What is the difference between welding with a wire without gas and what is welding by a semi-automatic method is discussed in this article.

Preparatory work before welding

Before starting work, semiautomatic welding machines must go through the following preparatory procedures:

- Checking whether the device is grounded. This requirement refers to one of the important conditions when working with any type of welding equipment.

- Mains voltage detection is required because most devices are very sensitive to low or high voltage.

- It is required to decide in advance on the welding mode. The settings will be individual depending on the purpose of the device, type of metal, type of wire and welding method.

- The diameter of the ferrule should be checked to match the size of the wire.

- Also, before starting work, check the settings of the burner and the feeder.

- And at the last stage, you should check the quality of the wire - so that it does not have dents, damage and other defects.

Semiautomatic welding with and without gas

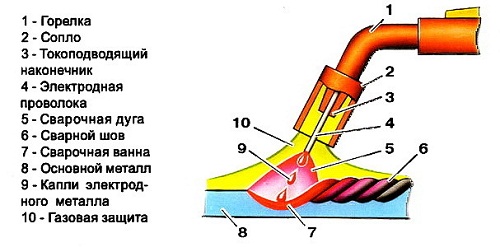

It is one of the traditional arc welding methods. In this case, the welding wire acts as a welded electrode. The wire is fed without stopping by a special mechanical drive at a predetermined speed to the welding point.

The use of welding fluxes makes it possible, even when using a wire with a small diameter, to provide a good and deep opening of the metal in the weld pool. Due to this, it is possible to obtain reliable seams when welding both thick and thin metal.

The use of a semiautomatic device can significantly improve the quality of the seam and the productivity of the work performed. Thanks to semi-automatic welding, specialists can create about 30 meters of a seam per hour.

Using gas

Welding with a semiautomatic device can be performed with or without gas. If used, it excludes the ingress of oxygen into the work area in order to exclude an excess of carbon or its shortage. Otherwise, the seam may be very brittle or too soft.

This method is quite laborious, because you have to carry gas cylinders and charge them quite expensively. In addition, the price for a semiautomatic welding machine without gas is much less, in contrast to this method of welding using gas.

Without using gas

For the use of gas-free welding, flux-cored wire and flux cored wire can be used. Flux cored wire is a steel tube, inside of which is contained powder for welding - flux. The combustion process creates a protective gas atmosphere in the area of the weld pool. Gas free flux cored wire welding is easier to use than conventional gas welding.

The use of the gas-free welding method has certain advantages:

- there is no need to use gas equipment;

- no need to spend money on filling the cylinders with gas, since when using the method without gas, the cost of costs compares favorably for the better;

- it is possible to change the chemical composition of the seam by using different types of wire.

Thus, the gas-free welding method is beneficial not only because it is more affordable for implementation, but also because it is more profitable from an economic point of view, since the cost of a semiautomatic welding machine without gas is much less expensive.

Welding with a semi-automatic method is similar to welding with conventional electrodes, therefore, when using this method, there is a risk of slag getting into the weld pool from burnt-out wire with filling. To prevent this phenomenon, it is recommended to make another one over the base seam. In this case, the first seam must first be cleaned.

Welding with flux-cored wire without gas requires the use of special mechanisms to prevent the wire from shrinking and breaking. Rough handling of the wire, sharp turns are also unacceptable.

The German brand Brima has been known to customers for over 50 years. The first welding machines were manufactured in Germany, today they are produced in China. Brim's products are delivered to ...

Almost any owner of a private house has a welding machine on the farm. But they can usually cook only parts made of ordinary thick-draft steel. It doesn't require ...