- One of the most common. It is easy to manufacture, with its help is easily implemented by a variety of buildings configurations. You can build a house in several floors or a small bath. To give concrete greater strength, and the basis of greater reliability foundations reinforced with steel rods of various configurations.

If there are steel elements in the design, this is no longer concrete, but reinforced concrete, and it has a strength at times higher. These works are not the simplest, but the work of the brigade is quite expensive. And it is not a fact that they will do as it should: for them it is only another order, but for the owner - a favorite house (bath, cottage, etc.). Therefore, the reinforcement of the foundation with their own hands is an excellent choice. There is only one nuance: if the soils are complicated, the subsidized waters are high, and the construction will also be difficult, ordering better calculation of the foundation in a specialized office. So you will have guaranteed correct and reliable base for the house in such difficult conditions.

Ribbon foundation - one of the most widely used in our country

The feature of the tape base is that their length is many times the width and height. The load from the building presses on the foundation from above. It turns out that at the same time the ribbon is compressed, and the bottom is stretched. Since there are cracks in the monolith in the monolith, then to ensure its integrity, the lower reinforcement belt is required.

The ribbon foundation of any height almost always has two reinforcement belts - upper and lower

On the other hand, from the bottom, periodically pressing the power tape, which appear when the soils are bent. Here the picture is the opposite - the bottom of the foundation is compressed, the top is stretched. And again in the stretching places are formed cracks. Therefore, to prevent their appearance and the top edge, it is necessary to strengthen.

Which is characteristic, the middle of the base is practically not loaded, and therefore whatever the height, the middle belt is rarely made.

If it is necessary to deepen the foundation strongly, it is advisable to order a professional calculation. Then the specialists will definitely tell you how many belts will be required to ensure that the structure stood for a long time, from which rod to do it.

It turns out that two belt belts are required for a belt foundation: one below, the other is at the top. And to protect against corrosion, they should be located 5 cm deep into the edge.

What fittings use

Now you need to understand, in which direction you need fittings, which thickness it should be. It depends on the distribution of loads, and they are distributed in this basis in such a way that most of all the impacts fall on the longitudinal rods. Therefore, they must be durable and corrugated - class AIII. On solid and delicate soils for small mass facilities, an armature with a diameter of 12 mm is used. On more complex soils or for heavier walls 14 mm are used. To be restred, laid 16 mm. Large diameters in low-rise construction - a rarity, although at times are placed 20 mm.

Vertical and transverse rebar of reinforcement in the tape foundation are loaded weakly. Mostly, they are needed to give shape and stabilize the design. Therefore, a smooth bar of 6-8 mm diameter is used for vertical and transverse racks. His strength is more than enough to perform these functions.

The pitch of the ribbon foundations (by SNU)

At the location of all rods, a key condition is observed: at least 5 cm of concrete should be from the edge to steel. Only in this case the valves turns out to be protected from corrosion (water and oxygen permanently penetrate into such a depth). But a strong blowing belt is also impossible: large forces affect the surface layers, the closer to the middle. Therefore, deep into the hide reinforcement should not: it will not fulfill its tasks. The distance from the edge is 5-6 cm - the optimal option.

For a ribbon foundation, it is necessary to determine the number of longitudinal rods in each of the belts. According to SNIPA 52-01-2003 (paragraph 7.3.6), the distance between them should be no more than 400-500 mm.

But the width of the tape for small buildings that the bath is (one-two-storey house too), it rarely happens more than 40 cm. If we consider that it will be necessary to retreat from the edges 5 cm, it turns out that the distance between two rods will be no more than 30 See, that is, 2 longitudinally laid "Armaturin" is quite enough.

Since the main loads account for precisely along the ribbon, then it is desirable to lay items, without compounds steel elements. On average, the length of the reinforcement of the required class is 6-11 m. This is enough for most houses and baths. Uncomfortable with delivery, but the base will be reliable. Moreover, take a rod at least 1.5 meters longer: they will need to bend when the corners pass. So it turns out securely and firmly.

The next step is to determine the step for the location of the vertical racks and the cross. To refer to again on SNiP. Only this time I need item 7.3.7. It says that transverse fittings in the tape foundation should be placed from each other at a distance of no more than 300 mm. There is some controversy: Practices say that on normal soils, it is enough to arrange the crossbars not closer than 500 mm. Moreover, even a brick house on this basis will stand normally. Actually, you decide. Do not know how to do - order the calculation. Or rearrate, and place after 300 mm. The foundation is the part in which it is better to overdo it. Cheaper will cost. Especially since the smooth bar is not so and roads.

Sometimes vertical and transverse racks in the ribbon fund make bent. It still increases its strength and reliability. And some, reinsured, put three rods ...

So, we have determined that laying of reinforcement in a ribbon foundation (up to a meter of height and up to 600 cm wide) is necessary in two tiers: one by 5x above the lower edge, the second is 5 cm below the top. In each belt there will be two corrugated longitudinal rods with a diameter of 12-14 mm. Vertical racks and transverse reinforcement passes through 300-500 mm and make them from a smooth rod 6-8 mm.

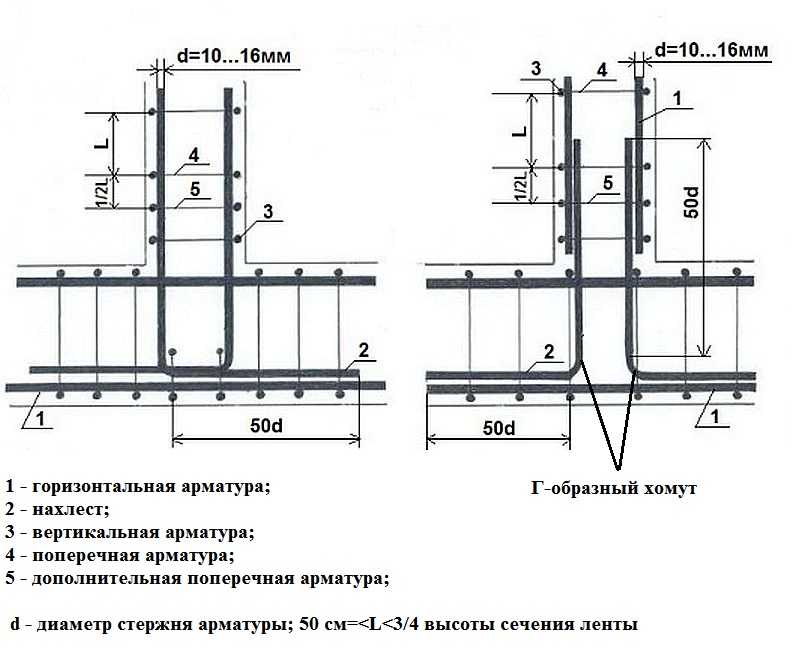

Reinforcement of ribbon foundation angles

The angles of any building are places where different loads of loads are connected. Therefore, it is so important to perform the reinforcement of the angles correctly. A simple connection of two rods is unacceptable here: it is unable to pass and distribute the load. This area requires a special approach and special laying of fittings.

For the correct strengthening, it is necessary to use bent elements. It is desirable that they are a continuation of longitudinal rods, and "logged in" an angle by 60-70 cm (see the scheme on the left).

If the lengths are missing, the elements are used in the form of the letter "g" - clamps. Their parties should be at least 50 diameters of rods (if you use 12 mm, then the sides should be at least 12 mm * 50 \u003d 600 mm, for 14 mm bar - 700 mm). As fit for the reinforcement in this case, it is shown on the right scheme.

Please note that in the corners of vertical and transverse belts you need to put two times more often: the reinforcement step is half smaller here.

No less attention also requires an increase in places, where ribbons under the inner partitions are departed from the main perimeter. The locations of these walls also require the use of bent items according to the same rules. The reinforcement scheme of the left shows how to lay a rod in the presence of a length of length, on the diagram on the right - using a separate M-shaped clamp.

Now you know how to proper fittings in the corners. Following these rules and implementing the scheme, you will create a solid base that will withstand the static load from the building itself, and on the forces of the sheep. And your building will never give cracks in the corners, with whom it is very difficult to fight.

When and how to install fittings

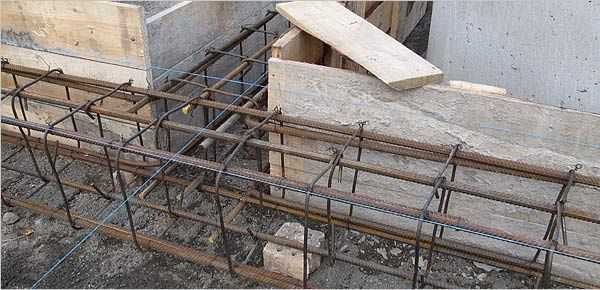

Reinforcement of the belt foundation begin after the formwork is collected and installed. Longitudinal and transverse guides need to somehow connect. There are two methods: welding and knitting wire. It is not recommended to weld it faster, but this method is not recommended: welding places are corrosive faster, and the design is obtained too tough as a result, which is worse than the loads. Therefore, desirable

With the connection method determined. Now you need to choose where to collect the frame. There are two methods:

Both methods are used. It is more convenient, probably the second - is in a narrow trench uncomfortable. In addition, it is possible to damage the film that the bottom and wall of the formwork often linse (to minimize the leaks of concrete and prevent it from drying out).

But with a high length of ready-made modules, it will be necessary to somehow deliver a completely difficult and fairly flexible design to the place, and even smoothly lower it on the bottom of the trenches. Here without technology can not do. So, too, there are difficulties and disadvantages.

RESULTS

Reinforcement of the belt foundation with their own hands - the case is not an easy, but quite real. One person will have to work for a long time, but also this option is real for small houses (country houses or baths).