Hot-rolled steel for reinforced concrete structures

Technical conditions

GOST 5781-82.

II.. Periodic profiles

State Standard of the SSR Union

Validity period from 01.07.83 to 01.07.94

This standard applies to hot-rolled round steel of a smooth and periodic profile, intended for reinforcing conventional and pre-stressed reinforced concrete structures (reinforced steel).

In terms of the norms of the chemical composition of low-alloy steels, the standard also extends to bars, blots and blanks.

1. Classification and sorting

1.1. Depending on the mechanical properties, the reinforcement steel is divided into classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600), A-V (A800), A-VI (A1000).

1.2. Reinforcement steel is made in rods or motges. A-I (A240) reinforcement steel (A240) is manufactured by smooth, Classes A-II (A300), A-III (A400), A-IV (A600), A-V (A800) and A-VI (A1000) - periodic profile.

At the request of the consumer, Steel classes A-II (A300), A-III (A400), A-IV (A600) and A-V (A1000) are made smooth.

1.1, 1.2. (Modified edition, change number 5).

1.3. Profile numbers, cross-sectional area, mass of 1 m The length of the reinforcement steel of a smooth and periodic profile, as well as the limiting deviations by weight for periodic profiles must be consistent with the specified in Table. one.

1.4. The nominal diameters of periodic profiles must correspond to the nominal diameters of isometrics on the cross-sectional area of \u200b\u200bsmooth profiles.

Table 1

|

Profile number (nominal rod diameter dN) |

Cross cross section area, cm2 |

Mass 1 m profile |

|

|---|---|---|---|

|

Theoretical, kg. |

Limit deviation,% |

||

| 6 | 0,283 | 0,222 | +9,0 -7,0 |

| 8 | 0,503 | 0,395 | |

| 10 | 0785 | 0,617 | +5,0 -6,0 |

| 12 | 1,131 | 0,888 | |

| 14 | 1,540 | 1,210 | |

| 16 | 2,010 | 1,580 | +3,0 -5,0 |

| 18 | 2,540 | 2,000 | |

| 20 | 3,140 | 2,470 | |

| 22 | 3,800 | 2,980 | |

| 25 | 4,910 | 3,850 | |

| 28 | 6,160 | 4,830 | |

| 32 | 8,010 | 6,310 | +3,0 -4,0 |

| 36 | 10,180 | 7,990 | |

| 40 | 12,570 | 9,870 | |

| 45 | 15,000 | 12,480 | |

| 50 | 19,630 | 15,410 | +2,0 -4,0 |

| 55 | 23,760 | 18,650 | |

| 60 | 28,270 | 22,190 | |

| 70 | 38,480 | 30,210 | |

| 80 | 50,270 | 39,460 | |

1.5. The mass of 1 M of the profile is calculated according to the nominal sizes at the density of steel, equal to 7.85 × 103 kg / m3. The probability of mass provision 1 m should be at least 0.9.

(Modified edition, change No. 3).

1.6. Limit deviations of the diameter of smooth profiles must correspond to GOST 2590-88 for conventional rolling accuracy.

1.7. The reinforcement steel of the periodic profile is round profiles with two longitudinal ribs and transverse protrusions running along a three-way screw line. For profiles with a diameter of 6 mm, protrusions are allowed along the same screw line, with a diameter of 8 mm-along a two-way screw line.

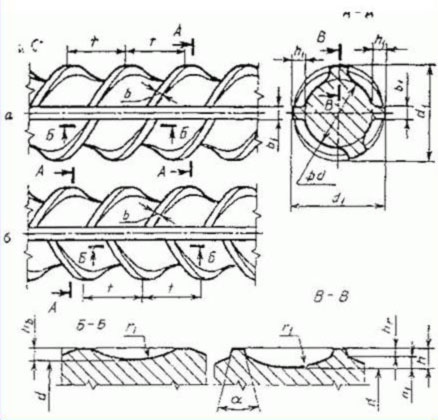

1.8. A-II (A300) reinforcement steel (A300), made in the usual performance, the profile shown. one a., and special purposes (AC-II) (AC300) profile shown. 2a should have protrusions running through screw lines with the same occasion on both sides of the profile.

Steel class A-III (A400), manufactured by a profile shown. one b., and A-IV classes (A600), A-V (A800), A-VI (A1000), the profile shown. one b., 2B, should have protrusions on the screw lines having the right profile on one side, and on the other left side.

The reinforcement steel of the special purpose of the class AS- II (AC300) is manufactured by the profiles shown. one but or 2 but.

The profile shown. 2. but, Special purpose is made in coordinating the manufacturer with the consumer. The shape and dimensions of the profiles shown. 2. but and b.can be refined.

1.9. Dimensions and limit deviations of the size of the reinforcement steel periodic profile manufactured by damn. one but and b.must correspond to the table below. 2, but by damn. 2. but and b.-Wed in table. 3.

table 2

Dimensions, mm.

|

Profile number (nominal diameter DN) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Previous from |

Previous from |

|||||||||

| 6 | 5,75 | 0,5 | ± 0.25 | 6,75 | 0,5 | 5 | 0,5 | 1?0 | 0,75 | |

| 8 | 7,5 | 0,73 | 9,0 | 0,75 | 5 | 0,75 | 1,25 | 1,1 | ||

| 10 | 9,3 | 1,0 | 11,3 | 1,0 | 7 | 1,0 | 1,5 | 1,5 | ||

| 12 | 11,0 | +0,3 | 1,25 | 13,5 | 1,25 | 7 | 1,0 | 2,0 | 1,9 | |

| 14 | 13,0 | -0,5 | 1,25 | 15,5 | 1,25 | 7 | 1,0 | 2,0 | 1,9 | |

| 16 | 15,0 | 1,5 | 18,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | ||

| 18 | 17,0 | 1,5 | ± 0.5 | 20,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 20 | 19,0 | 1,5 | 22,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | ||

| 22 | 21,0 | +0,4 | 1,5 | 24,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 25 | 24,0 | -0,5 | 1,5 | 27,0 | 1,5 | 8 | 1,5 | 2,0 | 2,2 | |

| 28 | 26,5 | 2,0 | 30,5 | 2,0 | 9 | 1,5 | 2,5 | 3,0 | ||

| 32 | 30,5 | 2,0 | 34,5 | 2,0 | 10 | 2,0 | 3,0 | 3,0 | ||

| 36 | 34,5 | +0,4 | 2,5 | ± 0.7 | 39,5 | 2,5 | 12 | 2,0 | 3,0 | 3,5 |

| 40 | 38,5 | -0,7 | 2,5 | 43,5 | 2,5 | 12 | 2,0 | 3,0 | 3,5 | |

| 45 | 43,0 | 3,0 | 49,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 50 | 48,0 | 3,0 | 54,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 55 | 53,0 | +0,4 | 3,0 | 59,0 | 3,0 | 15 | 2,5 | 4,0 | 4,5 | |

| 60 | 68,0 | 1,0 | 3,0 | ± 1.0 | 64,0 | 3,0 | 15 | 2,5 | 4,0 | 5,0 |

| 70 | 68,0 | +0,5 | 3,0 | 74,0 | 3,0 | 15 | 2,5 | 4,5 | 5,5 | |

| 80 | 77,5 | -1,1 | 3,0 | 83,5 | 3,0 | 15 | 2,5 | 4,6 | 5.5 | |

Note. At the request of the consumer, the limit variations of the size d 1. should not exceed the limit deviations d.plus double limit deviations h.

Table 3.

Dimensions, mm.

|

Profile number (nominal diameter d N.) |

a., hail |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Previous Off |

Previous Off |

||||||||||||

| 10 | 8,7 | 1,6 | ± 0.5 | 11,9 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 1,5 | 11 | ||

| 12 | 10,6 | 1,6 | 13,8 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 2,0 | 11 | |||

| 14 | 12,5 | +0,3 | 2,0 | 16,5 | 2,0 | 0,8 | 1,2 | 12 | 1,0 | 2,0 | 12 | ||

| 16 | 14,2 | -0,5 | 2,5 | 19,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 18 | 10,2 | 2,5 | +0,65 | 21,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 20 | 18,2 | 2,5 | -0,85 | 23,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | 50 | |

| 22 | 20,3 | +0,4 | 2,5 | 25,3 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 25 | 23,3 | -0,5 | 2,5 | 28,3 | 2,5 | 1,0 | 1,5 | 14 | 1,2 | 2,0 | 14 | ||

| 28 | 25.9 | 3,0 | 31,9 | 3,0 | 1,2 | 1,8 | 14 | 1,2 | 2,5 | 14 | |||

| 32 | 29,8 | +0,4 | 3,2 | +1,0 | 36,2 | 3,2 | 1,2 | 2,0 | 16 | 1,5 | 3,0 | 14 | |

| 36 | 33,7 | -0,7 | 3,5 | -1,2 | 40,7 | 3,5 | 1,5 | 2,0 | 18 | 1,5 | 3,0 | 19 | |

| 40 | 37,6 | 3,5 | 44,6 | 3,5 | 1,5 | 2,0 | 18 | 1,5 | 3,0 | 19 | |||

1.10. The relative shifts of the screw protrusions on the parties to the profile separated by the longitudinal ribs are not normalized.

The dimensions that the limit deviations are not installed are shown to build a caliber and are not checked on the finished profile.

1.11. The ovality of smooth profiles (the difference of the largest and smallest diameters in one section) should not exceed the sum of the positive and minus limit deviations in diameter.

1.9-1.11. (Modified edition, change No. 3).

1.12. The reinforcement steel of class A-I (A240) and A-II (A300) with a diameter of up to 12 mm and class A-III (A400) with a diameter of up to 10 mM is inclusive, manufactured in motges or rods, large diameters-in rods. The reinforcement steel class A-IV (A600), A-V (A800) and A-VI (A1000) and A-VI (A1000) of all sizes are made in rods, diameter 6 and 8 mm are manufactured by coordinating the manufacturer with the consumer in motges.

1.13. Rods produce from 6 to 12 m long:

- dimensional length;

- dimensional length with non-meter segments of at least 2 m long no more than 15% of the mass of the party;

- never-length.

In the battery of the neuroral length rods, the presence of a rods from 3 to 6 is allowed and no more than 7% of the mass of the batch.

In coordination of the manufacturer with the consumer, the manufacture of rods from 5 to 25 m is allowed.

1.14. Limit deviations on the length of the dimensional rods must correspond to the given in Table. four.

Table 4.

The rods of increased accuracy are manufactured at the request of the consumer.

1.15. The curvature of the rods should not exceed 0.6% of the measured length.

Examples of conventional designations

Reinforcement steel with a diameter of 20 mm, class A-II (A300):

20-A-II (A300) GOST 5781-82

Reinforcement steel with a diameter of 18 mm, class A-I (A240):

18-A-I (A240) GOST 5781-82.

In the designation of a class A-II class rods, an index C: AS- II is added.

(Modified edition, change No. 4).

2. Technical requirements

2.1. The reinforcement steel is manufactured in accordance with the requirements of this Standard for the Technological Regulations approved in the prescribed manner.

2.2. The reinforcement steel is made of carbon and low-alloyed steel grades specified in Table. 5. Mark steel is indicated by the consumer in the order. In the absence of instructions, the manufacturing company sets the brand. For the rods of the class A-VI (A1000), the steel grades are installed by coordinating the manufacturer with the consumer.

Table 5.

| Class of reinforcement steel | Profile diameter, mm | steel grade |

|---|---|---|

| A-I (A240) | 6-40 | ST3KP, ST3PS, ST3SP |

| A-II (A300) | 10-40 | ST5SP, ST5PS |

| 10-80 | 1n2s | |

| AC-II (AC300) | 10-32 | 10GT |

| (36-40) | ||

| A-III (A400) | 6-40 | 35GS, 25G2S. |

| 6-22 | 32G2RS | |

| 10-18 | 80s. | |

| A -IV (A600) | (6-8) | |

| 10-32 | 20Hg2c | |

| (36-40) | ||

| (6-8) | ||

| A-V (A800) | 10-32 | 23x2g2t |

| (36-40) | ||

| A-VI (A1000) | 10-22 | 22x2g2A, 22x2g2p, 20x2g2c |

Notes:

1. The manufacture of reinforcement class A-V (A800) is allowed. From steel grades 22x2g2a, 22x2g2p and 20x2g2c.

2. The dimensions specified in brackets are manufactured by the manufacturer with the consumer.

(Modified edition, change No. 3, 4).

2.3. The chemical composition of reinforcement carbon steel should correspond to GOST 380-88, low-alloyed steel-standards shown in Table. 6.

Table 6.

Brands of steel |

Mass fraction of elements,% |

|||

|---|---|---|---|---|

|

Manganese |

||||

| 10GT | No more than 0.13. | 1,00-1,40 | 0,45-0,65 | No more than 0.30 |

| 18G2S | 0,14-0,23 | 1,20-1,60 | 0,60-0,90 | No more than 0.30 |

| 32G2RS | 0,28-0,37 | 1,30-1,75 | No more than 0.17 | No more than 0.30 |

| 35GS | 0,30-0,37 | 0,80-1,20 | 0,60-0,90 | No more than 0.30 |

| 25G2S | 0,20-0,29 | 1,20-1,60 | 0,60-0,90 | No more than 0.30 |

| 20Hg2c | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 0,90-1,20 |

| 800 | 0,74-0,82 | 0,50-0,90 | 0,60-1,10 | No more than 0.30 |

| 23x2g2t | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,35-1,70 |

| 22x2g2Ayu | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,50-2,10 |

| 22x2g2p | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 1,50-1,90 |

| 20x2g2cr | 0,16-0,26 | 1,40-1,80 | 0,75-1,55 | 1,40-1,80 |

Continuation of table. 6.

Brands of steel |

Mass fraction of elements,% |

||||||

|---|---|---|---|---|---|---|---|

Zirconium |

Aluminum |

||||||

| 10GT | 0,015-0,035 | - | 0,02-0,05 | 0,0-10 | 0,030 | 0,30 | |

| 18G2S | - | - | - | 0,30 | 0,045 | 0,040 | 0,30 |

| 32G2RS | - | - | 0,001-0,015 | 0,30 | 0,050 | 0,045 | 0,30 |

| 35GS | - | - | - | 0,30 | 0,045 | 0,040 | 0,30 |

| 25G2S | - | - | - | 0,30 | 0,045 | 0,040 | 0,30 |

| 20Hg2c | - | 0,05-0,14 | - | 0,30 | 0,045 | 0,045 | 0,30 |

| 80s. | 0,015-0,040 | - | - | 0,30 | 0,045 | 0,040 | 0,30 |

| 23x2g2t | 0,02-0,08 | - | 0,015-0,050 | 0,30 | 0,045 | 0,045 | 0,30 |

| 22x2g2Ayu | 0,005-0,030 | - | 0,02-0,07 | 0,30 | 0,040 | 0,040 | 0,30 |

| 22x2g2p | 0,02-0,08 | - | 0,015-0,050 | 0,30 | 0,040 | 0,040 | 0,30 |

| 20x2g2cr | 0,02-0,08 | - | 0,05-0,050 | 0,30 | 0,040 | 0,040 | 0,30 |

2.3.1. In steel brands 20HG2Cs, an increase in the mass fraction of chromium is allowed to 1.7% and zirconium replacement by 0.02-0.08% titanium. In steel grade 23X2G2T, a titanium replacement is allowed to 0.05-0.10% of zirconium. In this case, in the designation of steel grades 20Hg2c instead of the letter C put the letter T, steel brand 23x2g2t instead of the letter T put the letter C.

In steel brands 32G2RPs allowed to replace aluminum by titanium or zirconia in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22X2G2A10 should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT - more than 0.008%.

2.3.3. Mass fraction of boron in steel brands 22x2g2p, 20x2 g2cp and 32g2pc should be 0.001-0.007%. In the steel brand 22x2g2a, the addition of boron 0.001-0.008% is allowed.

2.3.4. Titanium additive in steel grades 18g2c, 25g2c, 35GS at the calculation of its mass fraction in finished rental 0.01-0.03%, in steel grade 35GS at the calculation of its mass fraction in the finished rolling, made in MOTKi, 0.01-0 06%.

2.4. Deviations on the chemical composition in the finished rental from carbon steel-according to GOST 380-88, from low-alloyed steels when complying with the norms of mechanical properties - along Table. 7. Minus deviations on the content of elements (except titanium and zirconium, and 20x2 g2cp silicon steel) is not limited.

Table 7.

| Elements | Limit deviations,% |

|---|---|

| Carbon | +0,020 |

| Silicon | +0,050 |

| Manganese | +0,100 |

| Chromium | +0,050 |

| Copper | +0,050 |

| Sulfur | +0,005 |

Phosphorus |

+0,005 |

| +0,010 | |

| Zirconium | -0,020 |

| Titanium | ± 0,010. |

Note. In coordination of the manufacturer with the consumer, steel can be made with other deviations on chromium, silicon and manganese.

(Modified edition, change No. 3).

2.5. Fitting steel classes A-I (A240), A- II (A300), A-III (A400), A-IV (A600) produce hot rolled, class AV (A800) - with low-temperature release, class A-VI (A1000) - with low-temperature leave or thermomechanical processing in the flow of rolling mill.

It is allowed not to carry out the low-temperature vacation of steel A-V classes (A800) and A-VI (A1000), subject to the preparatory elongation of at least 9% and uniform elongation of at least 2% when tested for 12 hours after rolling.

2.6. The mechanical properties of reinforcement steel must comply with the standards specified in Table. eight.

Table 8.

|

Class of reinforcement steel |

Yield strength sT |

Temporary resistance rupture sV |

Relative extension d5, % |

Uniform elongation d R., % |

Shock viscosity at a temperature of -60 ° C |

Bending test and cold condition ( from- sending sending, d.-Diameter rod) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

|

kgf × m / cm2 |

||||||||||

| A-I (A240) | 235 | 24 | 373 | 38 | 25 | - | - | - | 180 °; c.= d. | |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | - | - | - | 180 °; from = 3d. | |

| AC-II (AC300) | 295 | 30 | 441 | 45 | 25 | - | 0,5 | 5 | 180 °; c.= d. | |

| A-III (A400) | 390 | 40 | 590 | 60 | 14 | - | - | - | 90 °; from = 3d. | |

| A-IV (A600) | 590 | 60 | 883 | 90 | 6 | 2 | - | - | 45 °; from = 5 D. | |

| A-V (A800) | 785 | 80 | 1030 | 105 | 7 | 2 | - | - | 45 °; from = 5d. | |

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | 2 | - | - | 45 °; from = 5d. | |

Notes:

1. In coordination of the manufacturer with the consumer, it is allowed not to test the test viscosity of the assembly of class AC-II (AC300).

2. (Excluded, change No. 3).

3. For reinforcement steel class A-IV (A600) with a diameter of 18 mm, the steel of 80c is the bending norm in the cold state is set at least 30 °.

4. For reinforcing steel class A-I (A240) with a diameter of over 20 mm with bending in a cold condition by 180 ° from = 2d., class A-II (A300) with a diameter of over 20 mm from = 4d.

5. The brackets indicate the conventions on the yield strength.

(Modified edition, change No. 1, 3).

For steel class A-II (A300) with a diameter of over 40 mm, a decrease in relative elongation is allowed by 0.25% per millimeter to increase diameter, but not more than 3%.

For steel AC-II class (AC300), a decrease in the time resistance to 426 MPa is allowed (43.5 kgf / mm2) with relative elongation: d 5.30% or more.

Notes:

1. S.- subsequent deviation in the general totality of testing;

SO-Connexual deviation in the melting party;

Average in the general totality of testing;

The minimum average value in the swimming party.

2. For reinforcement steel in motges, a diameter of 6 and 8 mm is allowed to increase the rules for S.and SO by 4.9 MPa (0.5 kgf / mm2).

3. (Excluded, change No. 5).

The probability of ensuring the mechanical properties specified in Table. 8 should be at least 0.95.

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, tension cracks, riban, rolling captivity and sunsets.

Small damage to the ribs and protrusions are allowed, in an amount of no more than three per 1 m length, as well as a slight rust, separate rolled pollution, imprints, influx, traces of rolled bubbles, ripples and flakes within allowable deviations in size.

(Modified edition, change No. 2).

2.9. The weldability of the reinforcement steel of all brands, except 80c, is provided by the chemical composition and manufacturing technology.

2.10. Carbon equivalent ![]() For the welded rod reinforcement from low-alloyed steel class A-III (A400) should be no more than 0.62.

For the welded rod reinforcement from low-alloyed steel class A-III (A400) should be no more than 0.62.

3. Rules of acceptance

3.1. The reinforcement steel is taken by parties consisting of one diameter profiles, one class, one melting-bucket and decorated by one quality document.

The battle weight must be up to 70 tons.

It is allowed to increase the mass of the batch to the mass of smelting-bucket.

3.2. Each batch is accompanied by a document on quality according to GOST 7566-81 with additional data:

3.3. To check the size and quality of the surface, select:

- in the manufacture of reinforcement steel in rods, at least 5% of the party;

- in the manufacture and serics, two shoes from each batch.

(Modified edition, change No. 3).

3.4. To verify the chemical composition of the sample, select GOST 7565-81.

Mass fraction of aluminum The manufacturer determines periodically, but at least once a quarter.

3.5. For tensile check, bending and shock viscosity from the party are selected two rods.

For the manufacturer of the manufacturer, the sampling interval must be at least half the time spent on rolling one size of a single batch profile.

(Modified edition, change No. 3).

3.6. Upon receipt of unsatisfactory test results, at least one of the indicators, repeated tests are carried out according to GOST 7566-81.

4. Test methods

4.1 Chemical analysis of steel is carried out according to GOST 12344-88, GOST 12348-78, GOST 12350-78, GOST 12352-81, GOST 12355-78, GOST 12356-81, GOST 18895-81 or other methods that ensure the required accuracy.

4.2. The diameter and ovality of profiles are measured at a distance of at least 150 mm from the end of the rod or at a distance of at least 1500 mm from the end of the wow with a mass of the wow to 250 kg and at least 3000 mM with a mass of a maximum of 250 kg.

4.3. Dimensions check the measuring instrument of the required accuracy.

4.4. From each selected rod for tensile testing, bending and shock viscosity is cut off one sample.

4.5. Sampling for tensile testing, bending and shock viscosity is carried out according to GOST 7564-73.

4.6. Tensile test is carried out according to GOST 12004-81.

4.7. The bending test is carried out according to GOST 14019-80 on the samples section equal to the cross section of the rod.

For the rods with a diameter of over 40 mm, the test of samples cut along the rod axis, on the mandrel, diameter, reduced by half compared to those specified in Table. 4, with an application of bend force from the cut side.

4.8. Determination of shock viscosity is carried out according to GOST 9454-78 on samples with a type 3 type concentrator for rods with a diameter of 12-14 mm and samples of type 1 for rods with a diameter of 16 mm and more. Samples are manufactured in accordance with the requirements of GOST 9454-78.

4.9. It is allowed to apply statistical and non-destructive methods for controlling the mechanical properties and mass of profiles.

4.10. The curvature of the rods is measured at the length of the profile supplied, but not shorter than 1 m.

4.11. Definition of statistical indicators of mechanical properties in accordance with the required application 2.

4.12. The quality of the surface is checked without the use of magnifying devices.

4.10-4.12. (Introduced additionally, meas. No. 3).

4.13. Measuring the height of transverse protrusions of the periodic profile should be carried out along the vertical axis of the cross section of reinforcement rolled steel.

(Introduced additionally, meas. No. 4).

5. Packaging, Marking, Transportation and Storage

5.1. Packaging, marking, transportation and storage-according to GOST 7500-81 with additions:

- the ends of the rods from the low-alloyed steels of class A-IV (A600) must be painted with red paint, class A-V (A800) - red and green, class A-VI (A1000) - red and blue. It is allowed to paint bundles at a distance of 0.5 m from the ends;

- the rods are packaged in bundles weighing up to 15 tons tied with wire or rod. At the request of the consumer, the rods are packaged in bundles weighing up to 3 and 5 tons;

- on a label attached to each rod binder, the adopted designation of the class of reinforcement steel (for example, A-III) or the conditional designation of the class on the yield strength (A400) is applied.

On bundles, paint is applied with stripes with a width of at least 20 mm on the side surface around the circumference (at least 1/2 of the circumference length) at a distance of no more than 500 mm from the end.

On the hundreds of paint is applied with stripes with a width of at least 20 mm across the turns from the outside of the sides.

The paint is applied to the non-fallen production to the end or on the side surface at a distance of no more than 500 mm from the end.

(Modified edition, change. No. 3, 5).

ATTACHMENT 1

Mandatory

Requirements for statistical indicators of mechanical properties

1. The manufacturer's enterprise guarantees the consumer averages of temporary resistance sVand yield strength (physical sTand conditional s0,2) in the general aggregate i.and the minimum average values \u200b\u200bof the same indicators in each melting party i.; The values \u200b\u200bof which are set from the conditions:

where x i b pBloom values \u200b\u200bvalues s B., s 0,2shown in table. 8 of this standard;

t.- Quantile value, taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for the rods of Class A-IV (A600), A-V (A800) and A-VI (A1000).

2. Control of the quality of indicators of mechanical properties of products at the manufacturer.

2.1. The required performance indicators of profiles are ensured by compliance with production technology and are monitored by the test according to the requirements of Section 3.5, PP. 4.4-4.8.

2.2. Values \u200b\u200b,, S.and S O.installed in accordance with the test results and the provisions of Annex 2.

3. Control of the quality of indicators of mechanical properties of products at the consumer enterprise.

3.1. The consumer in the presence of a document on the quality of the products of the highest category of quality may not test mechanical properties.

3.2. If you need to check the mechanical properties from each batch, a test of six samples taken from different packets or motors and from different profiles are carried out and the following conditions are checked.

where in - the average value of mechanical properties according to the test results of six samples;

tmin.- The minimum value of the test results of six samples.

3.3. Minimum values \u200b\u200bof relative elongation d 5.and uniform elongation d R.there must be no less values \u200b\u200bgiven in Table. eight .

(Modified edition, change No. 3).

Appendix 2.

Mandatory

Methodik

Definitions of statistical indicators of the strength characteristics of the mechanical properties of hot-rolled rolling for reinforced concrete structures

The present method applies to hot rolled, accelerated-cooled, thermomechanically and thermally strengthened rental of periodic profile made in motges or rods.

The technique is used in assessing the reliability of mechanical properties in each wop and steel batch in general, monitoring the stability of the technological process.

1. To identify statistical indicators of mechanical properties (physical yield strength sTor conditional s0,2, time resistance rupture sV) Test test results started by the general aggregates.

2. Compliance with the mechanical properties of rolling with the requirements of the regulatory and technical documentation is determined on the basis of statistical processing of test results forming a sample from the general population. All conclusions, results and conclusions made on the basis of the sample belong to the entire general population.

3. Sampling - a set of results of control tests that form an information array to be processed.

The sample includes the results of the delivery tests of the rolled one class, one brand and method of smelting, rolled to one or group of close profile sizes.

4. Sample, on the basis of which the statistical indicators are calculated, must be representative and cover a sufficiently long period of time, but at least three months during which the process does not change. If necessary, the time interval for the sample can be increased. Check the homogeneity of the sample on the regulatory and technical documentation.

5. The number of melting batches in each sample should be at least 50.

6. When forming a sample, the condition of accidental sampling from the swimming party should be observed. The assessment of the abnormality of test results is carried out according to regulatory and technical documentation.

7. With statistical processing, the average value is determined, the average quadratic deviation s of each sample (general aggregate), the average quadratic deviation within the melting party SO, as well as the average quadratic deviation of smelting medium S1.. Value S1.determined by the formula

Values S. Defined on regulatory and technical documentation.

8. Check stability characteristics and S. Conducted in accordance with OST 14-34-78.

9. Value SO.it is determined for accelerated-cooled, thermomechanically and thermally hardened reinforcement steel, only the experimental method for the hot-rolled-experimental method and method of scope by the formula, where S V.accordingly, the average value and the average quadratic deviation of the discharge distribution over two tests from the party. Minimum value SOequal 1.

10. Definition of value SOan experimental method is made at least two melts for each steel grade, class and profile of rolled products by random selection of at least 100 samples from each melting.

11. The magnitude of the minimum average strength characteristics sT(s0,2), sV in every wage batch 2 determined from the condition i.= - t.× S. 1 where t.- quantile value 1.64 for the probability of 0.95.

12. The minimum value of the results of tensile tests of two samples ( n.\u003d 2) of each batch subjected to control should be at least xmin.defined by the formula

![]() .

.

13. To ensure the guarantee, the consumer of mechanical properties must be satisfied with the following conditions:

where xi Br.- Bracker value sT(s0,2) I. sVspecified in the relevant regulatory and technical documentation.

(Introduced additionally, out of No. 3).

1. Classification and sorting

2. Technical requirements

3. Rules of acceptance

4. Test methods

5. Packaging, Marking, Transportation and Storage

Appendix 1 mandatory.Requirements for statistical indicators of mechanical properties

Appendix 2 mandatory. Methods for determining the statistical indicators of the strength characteristics of the mechanical properties of hot-rolled rolling for reinforced concrete structures.

Information details

1. Developed and introduced by the Ministry of Black Metallurgy of the USSR, the USSR State Building

Developers

N. M. Vorontsov, Cand. tehn sciences; I. S. Ghin., Cand. tehn sciences; K. F. Peretta; G. I. Snimshchikova; L. G. Big, E. D. Gavrilenko; Cand. tehn sciences; K.V.Mikhailov, Dr. tech. sciences; S. A. Madathan, Cand. tehn sciences; N. M. Mulin, Cand. tehn sciences; V. Z. Miskov, Cand. tehn sciences; B. P. Goryachev, Cand. tehn sciences; B. N. Friedlas; V.I. Petina

2. APPROVED AND INTRODUCED RESOLUTION of the USSR State Committee on Standards No. 17.12. № 4800

3. Instead of GOST 5.1459-72, GOST 5781-75

4. Reference regulatory and technical documents

| Designation of the OTD to which the link is given | Point number |

| GOST 380-88 | 2.3, 2.4 |

| GOST 2590-88 | 1.6 |

| GOST 7564-73 | 4.5 |

| GOST 7565-81 | 3.4 |

| GOST 7566-81 | 3.2, 3.6, 5.1 |

| GOST 9454-78 | 4.8 |

| GOST 12004-81 | 4.6 |

| GOST 123.14-88 | 4.1 |

| GOST 12348-78 | 4.1 |

| GOST 12350-78 | 4.1 |

| GOST 12352-81 | 4.1 |

| GOST 12355-78 | 4 1 |

| GOST 12356-81 | 4.1 |

| GOST 14019-80 | 4.7 |

| GOST 18895-81 | 4.1 |

| OST 14-34-78 | Appendix 2. |

5. Reprinted with amendments No. 1, 2, 3, 4, 5, approved in February 1984, June 1987, December 1987, October 1989, in December 1990 (IUS 5-84, 11- 87, 3-88, 1-90, 3-91).