Welded reinforcement grid (CAC) applies when performing a number of important construction activities. It is indispensable with reinforcing the reinforcement of monolithic reinforced concrete structures and with other works.

1 reinforcement grid - and where only it does not apply!

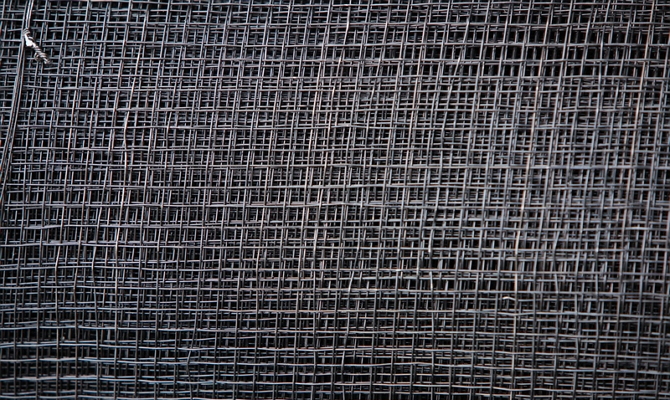

CAC is a steel grid made by a cold hood from low carbon wire. Its cells are combined with welding. The profile of the finished product is periodic or ordinary smooth.

The surface of the grid is allowed to apply a variety of protective coatings. They, firstly, increase the technical indicators of the mesh structure, and secondly, significantly expand its area of \u200b\u200buse.

The reinforcement grid of steel, which is also called reinforced, very reliable and durable. Most often it is used in the following areas:

- Building. The CAC is used in the construction and arrangement of the walls, guaranteeing them unique strength indicators. If you take the grid with the rods of the increased thickness, it can be created differently in the direction and complexity of the foundations in structures and buildings. Also reinforced net products are suitable for performing other rehabilitation and repair activities in the field of modern construction.

- Road works. The use of a grid for reinforcing from steel guarantees receiving roads of the highest quality. Their laying becomes faster and simple, and the strength of the resulting design is at a very high level. It is appropriate to the use of grids for reinforcement when carrying out planned road repairs.

- Household. Constructions from low carbon wire can now be seen on many nauded and garden sites. In this case, the reinforced CAC makes it possible to build any framework structures, whether large greenhouses or small greenhouses, as well as all sorts of fences.

- Finishing work. Described mesh products made of wire well proven themselves with the internal finishing of the premises. Easy CAC types provide high-quality leveling of irregularities on wall and ceiling surfaces and at the same time optimize and accelerate plaster events.

In addition, the reinforcement grid is currently very actively operated by bridge builders. It is used to strengthen bridges, their supports and other elements of such structures.

Two advantages of grids - competitors, envy!

CAC has a truly unique combination of excellent performance and technical indicators (weight, strength, and so on). At the expense of this, it can be used on the most complex industrial and construction sites, having always obtained a flawless result of the work.

The reinforced grid is described by such advantages of use:

- Multifunctionality - there is no such branch of modern industrial production, where the CAC would not be applied. And with each day of the area of \u200b\u200bits use expands.

- The acceptable cost of the material from the wire with a small content of carbon - the compete grids lose the CAC at the cost of their production. Increasing the cost of production of steel products, naturally, increase their selling price.

- The cost-effectiveness of work is to reduce the time of construction and other events, as well as simplifying the technological process.

- Small specific weight, convenience of fasteners, operation of operation and ease of installation

It is also worth noting a large selection of geometric sizes of reinforced grids allowed by GOST 23279-2012. This state standard, which describes all the requirements for the CAC, will consider in more detail below. In addition, the finished mesh products without any problems are transported and can be stored in almost any conditions.

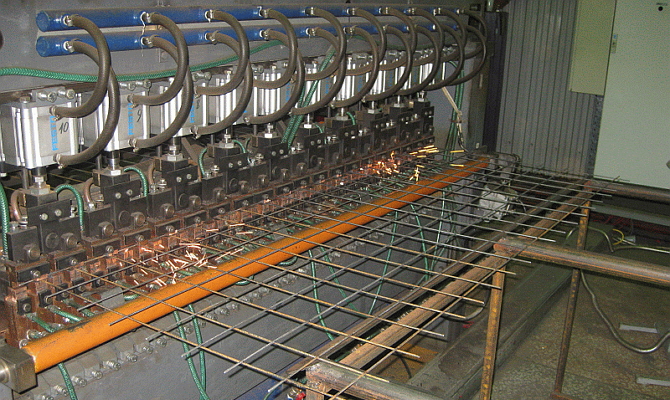

All specified advantages are achieved due to the fact that the CAC is manufactured on innovative equipment on the latest technologies that are adopted in the entire civilized world. In the production of nets from wires with a small carbon is used, it can also be used. Due to this, ready-made grid structures become highly resistant to mechanical external influences and receive an excellent strength indicator.

To increase the anti-corrosion protection of the CAC on its surface, a special layer may be applied (most often zinc). Such processing is performed according to electrolytic technology or a method of hot applying a protective coating. Both techniques have proven themselves well. It is usually selected that technology that allows you to get a layer of a given thickness in each particular case and a certain appearance.

3 GOST 23279 - What should be the grids for reinforcement?

This standard describes rolled and flat CAC with a cross section of 3-40 mm, in which the rods that are elements of the mesh design are perpendicular to each other. The considered products according to GOST 23279 are divided into different species by the method of placing fittings (working) and on the cross section of the rods.

The armature in welded nets from low carbon wire can be located in transverse and longitudinal directions, only in transverse or only in the longitudinal. By section of the rod, the product is divided into light and heavy. Under the last GOST implies CAC, in which the rods in one direction have a cross section of more than 12 mm. Lightly call structures with transverse and longitudinal rods not more than 10 mm in diameter.

There are five types of welded grids from steel:

- With longitudinal reinforcement (working), a cross section of which is more cross-section of distribution fittings. Such products refer to heavy.

- Armature in both directions, heavy.

- With the transverse reinforcement of a large cross section, heavy.

- With displaced rods located transversely, lungs.

- With rods (transverse) to the entire existing CAC width.

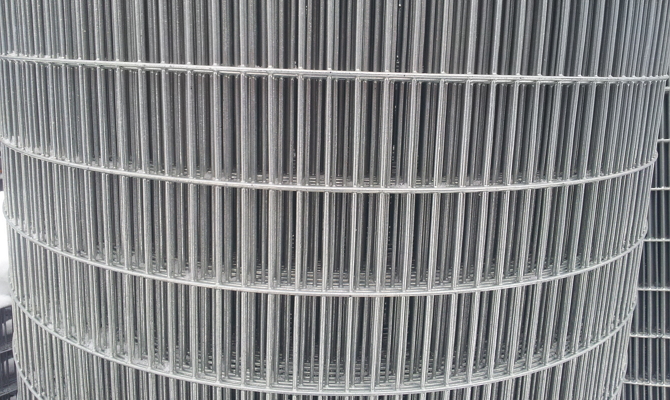

GOST allows producing designs from wire with rectangular and square cells, in rolls or in a flat form. Pay attention - in rolls it is allowed to produce exclusively 3-5-millimeter light CAC from whose weight does not exceed the values \u200b\u200bspecified in the standard.

The cross sections of the working fittings for reinforcement products are determined taking into account the area of \u200b\u200bcross section (transverse) reinforcement elements (calculation should be calculated in which not only the diameter, but also the weight of the latter). The ratio of the cross section of a smaller rod to more is obliged to be 0.25. The CAC should have (necessarily!) Same on the diameter of the rods in one direction.

The weight of the grid is determined by its type (light, heavy), long, width and cross section of the rods used. If the design is manufactured, for example, from rods with a diameter of 4 mm, with dimensions of 200 per 600 cm and with 20 cm cells, the mass of one square meter will be 0.99 kg. But the weight of the grids with the same parameters, but made from the cross section of 8 mm, will be already 3.95 kg.

4 Other requirements of the State Standard - this is important!

According to GOST 23279 for heavy grids for reinforcing the working reinforcement, the reinforcement steel (rod) section of 10-40 mm CLASS A600C, A500C, A400 is a cross section. It is allowed to use the rods of hot-rolled alloys A240. Lightweight CACs are made of wire with a cross section of up to 5 mm (type B-I, BP-I) or from reinforcement steel 6-10 mm CLASS A240, A500C, A400, B500C.

GOST clearly stipulates the intersection of rods in a wire and rod periodic armature can be welded in a chess manner through two or one position. At the same time, in all intersections, two last rods in the mesh design should be connected. If the CAC is made of steel A240, all without exception is welded.

Connections of the cross-shaped form in the described products are welded with a point technology according to GOST 14098. Welding modes for performing this operation are selected based on the requirements of the existing regulatory documentation.

The temporary resistance and discontinuous force of the rods of the grid in the places of their welding is checked according to the standard 10922. The strength to the slice must correspond to the provisions of the same GOST.

Acceptance of CAC is carried out in rolls or parties. In addition to all standard analyzes, additional checks are undergoing additional checks on the precipitation of the rods and the magnitude of their rectinity.

The reinforced grid binds to packages weighing no more than three tons. In mandatory, packets are binding to four sections with a soft metal wire. If the product comes in rolls, the bundle is performed in three or more places.

Mesh transportation is made in a horizontal position. At the same time, it is necessary that the packages relieve on 3-centimeter gaskets either to the wooden bars similar in thickness. Storage CAC is carried out in the same way.