The question of how to correctly execute column reinforcement made of concrete, first of all worries those people who lead dIY house construction without a professionally designed project. Undoubtedly, this is not the best option for building a dwelling, but many people build this way. Build by consulting experienced builders or trying to find the information you need on the Internet. Tips - advice, but it is best to order the calculation of columns in the design organization. True, not everyone has such an opportunity. And among the large amount of information on this topic available on the Internet, almost all inexperienced people are looking not for formulas for calculating monolithic columns, but for a simple advice: do this. To help such people, I will try to give the maximum amount of information, using standard schemes as an example. column reinforcement for country houses of medium size.

Anticipating the comments of professional builders about the content of this article because of the deviation from the rule, it is necessary to perform calculations, I want to ask them about this. If, according to the schematic design of the future house, on the first floor in the middle of the building there will be only one or two (with spans less than 6 meters), and there will be an attic floor on the monolithic floor of the first floor, why fool people with calculations, especially if they do not have the opportunity to contact a design organization? It is quite another matter if the constructive scheme of the future house will consist of monolithic columns and monolithic floor, and the walls will be built from lightweight materials. In this case, the calculation of columns and floors is required!

Correct column reinforcement - the guarantee of the strength of the whole house. At the same time, you should not reinforce monolithic columns, using the common phrase that the more metal, the stronger the structure. In addition, the location of the main and assembly fittings in the column frame has a decisive influence on the stability of this structure.

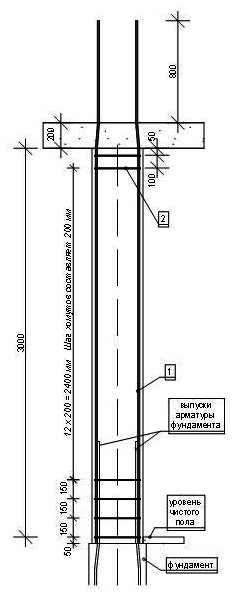

The section of a monolithic column depends on the total load acting on it. Most often, a section of 400x400 mm is used, although, according to the results of calculations, it is possible to arrange monolithic columns with a section of 300 x 300 mm. By the way, the first section coincides in size with the parameters of a brick column with a thickness of 1 ½ brick, but a monolithic column has greater strength. Therefore, I suggest you consider the reinforcement of a column made of concrete of exactly this section.

The standard reinforcement scheme of a monolithic column consists of four vertical rods of the main, working reinforcement Ø 14-16 mm A 400C, which is connected into a single structure using mounting reinforcement Ø 6 mm A 240C.

In order not to violate the properties of reinforcing bars at the points of their connection with other reinforcement, which inevitably occurs as a result of welding, it is better to “tie” the column reinforcement frame using a knitting wire Ø 1-1.2 mm. In addition, this method is more acceptable for those who have no experience in performing welding. To make it easier to knit the reinforcement cage, you can make a simple hook from a wire Ø 6 mm. But before the direct assembly of the column frame, its main working rods must be given a certain shape, and frames - clamps must be made from the mounting reinforcement, which is quite easy to do with a simple bending device.

Main reinforcement in the column

Depending on the structural scheme of your future home and the location of the columns, as well as,

accordingly, the load acting on them changes not only the diameter of the main reinforcement, but also its shape. So, if the columns in your house will be not only on the first, but also on the second floor, then the length of the columns of the first floor is determined taking into account the following values:

- Distance from the top of the foundation under the column to the level of the finished floor;

- Floor height (from the level of the finished floor to the bottom of the monolithic floor);

- Monolithic floor thickness;

- To the resulting sum of values, it is necessary to add 800 mm - it is to this height that the rods should protrude above the monolithic floor to securely connect the frames of the columns of the first and second floors.

In addition to such a release of reinforcement, for a reliable connection of the column frames to each other, the upper end of the bars of the lower column must have a bend, as shown in Scheme 1. monolithic overlap.

And one more detail. The main taper bars should be installed so that the offset of each bar is directed towards the center of the column.

If in your house they will be located only on one floor and serve to support the monolithic floor, to provide an additional connection between the frame of the monolithic floor and the column, the working rods in the upper part are bent, as shown in diagram 2. In this case, the length of the rods compared to the first calculation option decreases by 400 mm. I will tell you about how the additional reinforcement of the frame of a monolithic floor in the place of support on the column is performed in the next post.

Structural reinforcement of the column frame

As mentioned above, it is much easier to assemble a column frame if the structural (assembly) reinforcement is bent with frames or, as we say, with clamps. The size of such a frame made of reinforcement Ø 6 mm A 240C for a column with a section of 400 x 400 mm is determined taking into account that the protective layer of concrete around the frame should be at least 20 mm on each side. Based on this, the length of one side of such a clamp frame should be no more than 360 mm on the outside. In addition, special bends are made along the edges of the workpiece, which provide the clamps on one of the main rods in one frame. The inner diameter of such bends must not be less than the diameter of the main reinforcement.

The location of the mounting hardware (clamps) along the length of the frame is uneven. The optimal arrangement of the clamps with an indication of the step size is shown in diagram 1. I also want to draw your attention to the lowest clamps installed in the lower part of the column frame. Since in this zone of the column, the outlets of the main reinforcement of the foundation and the main frame of the column are connected, the bars in the lower part will be double. Therefore, the length of the bends at the edges of the clamp blank should be

more than shown in diagram 3 in order to capture two rods at once. In addition, it is necessary to install the lower clamps from the mounting reinforcement Ø 6 mm A 240C not during the manufacture of the column frame, but after its connection with the reinforcement outlets of the foundation. Otherwise, in a critical situation with a strong side impact, ready monolithic column may just fall off as shown in the photo. Judging by the outlets of the foundation reinforcement, they are of insufficient length, and the clamps installed on the column frame were simply removed from such short outlets.

1.Formwork device

Climbing formwork

Sliding formwork

Volumetric movable formwork

Rolling formwork

Formwork-facing

2.Reinforcement work

Installation of stress-free fittings

Column reinforcement

Reinforcement of beams, purlins and girders

Quality control of work and acceptance of mounted fittings

3. Installation of building structures

Mounting accessories

Structural erection methods

Installation of reinforced concrete structures of multi-storey frame buildings

1 Formwork device

Formwork is the form into which reinforcement and concrete are laid on the construction site.

The formwork must be strong, rigid, stable, maintain the specified design shape and dimensions. The design of the formwork should ensure its quick assembly and disassembly, and the accepted option is the most economical in comparison with others.

On the basis of repeated use, inventory formwork is distinguished, i.e. reusable and stationary - used for only one structure or structure. One of the ways to reduce the cost of formwork work is to reuse it.

Wooden plank formwork has a 10-fold turnover rate, waterproof plywood - 25-fold, metal - 100- and 300-fold, but has a high initial cost.

By the material of the formwork, they are distinguished: plank, made of waterproof plywood, metal, made of synthetic materials and combined.

According to the method of production of work, formwork is:

Collapsible and adjustable;

Volumetric adjustable;

Sliding;

Lifting-adjustable;

Rolling;

Formwork-facing.

Dismountable formwork, the most common in comparison with other formwork, is used in the construction of foundations, walls, columns, beams, floor slabs and coverings. The formwork is used small-panel, large-panel and block.

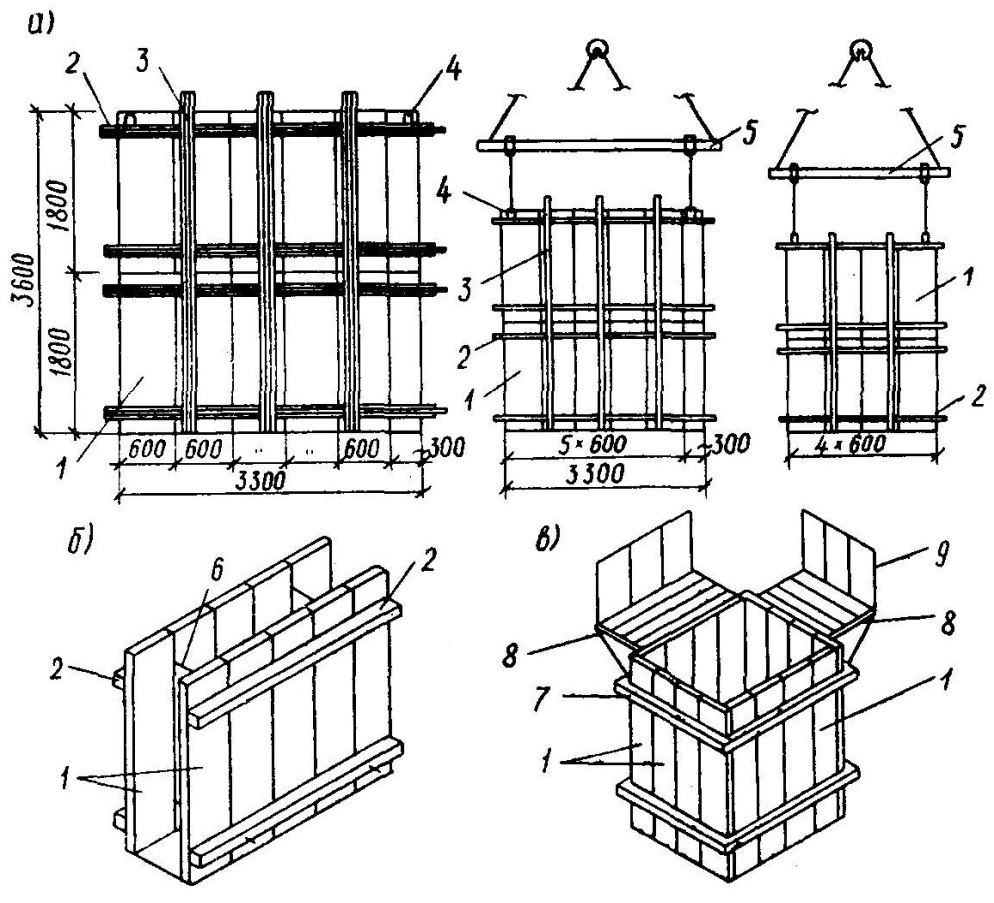

Small-panel formwork consists of several types of panels: flat, L-shaped or curved. The dimensions of the boards are multiples of the module 100 mm in height (width) and 300 mm in length.

The area of \u200b\u200bthe panels is up to 2.0 m2, consists of a set of fastening elements and supporting devices, the mass of such formwork elements does not exceed 50 kg. Formwork assembly and disassembly is done manually.

In order to mechanize the formwork and reduce their labor intensity, small-panel formwork can be pre-assembled into large-size formwork panels or blocks, which are installed and removed by crane.

In the small-panel formwork, molds can be assembled for almost any concrete and reinforced concrete structures. The versatility of the formwork is achieved by the ability to connect panels on any edges.

Figure: 1.1. Small-panel collapsible formwork:

a - flat shields; b - corner boards; в - fastening elements; d - supporting devices; d - knot for attaching the shields to the fight; e - panel connection node; 1 - shield frame; 2 - shield deck; 3 - slab formwork shield in working position; 4 - fight; 5 - telescopic rack; 6 - girder truss; 7, 8 - sliding girders; 9 - mounting corner; 10 - corner post; 11 - traction; 12 - tapered spacer; 13 - washer; 14 - nut; 15 - tubular spacer; 16 - pad; 17 - hook; 18 - wedge; 19 - spring bracket

To reduce the labor intensity of the work, the small-panel formwork is enlarged and installed in the design position using a crane.

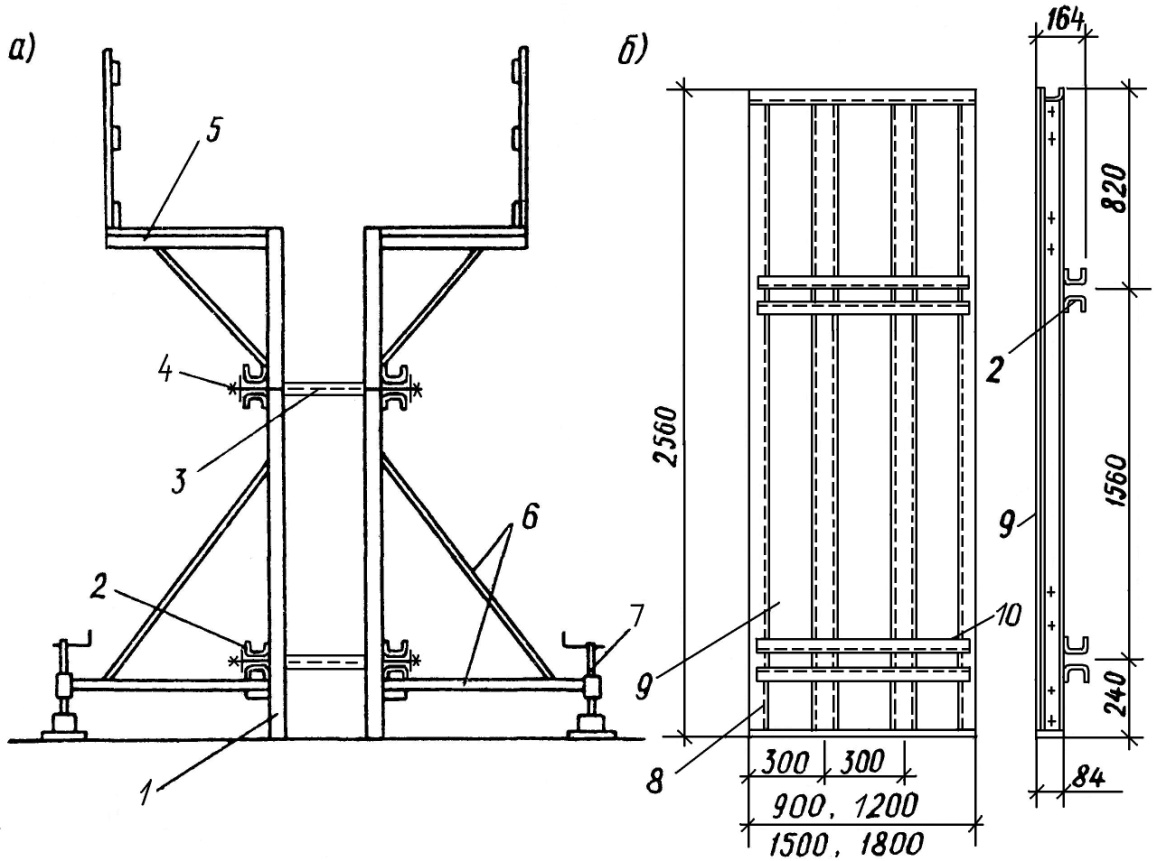

For the construction of monolithic walls of frameless civil buildings, large-panel formwork "Grazhdanstroy", "Monolitstroy", etc. are used.

Formwork "Grazhdunstroy" consists of shields, fastening elements, supporting and auxiliary devices. Formwork panels have a width of 0.9; 1.2; 1.5 and 1.8 m, height - 2.56; 2.76 and 3.06 m. They are made with a frame made of bent sections and a deck made of sheet iron.

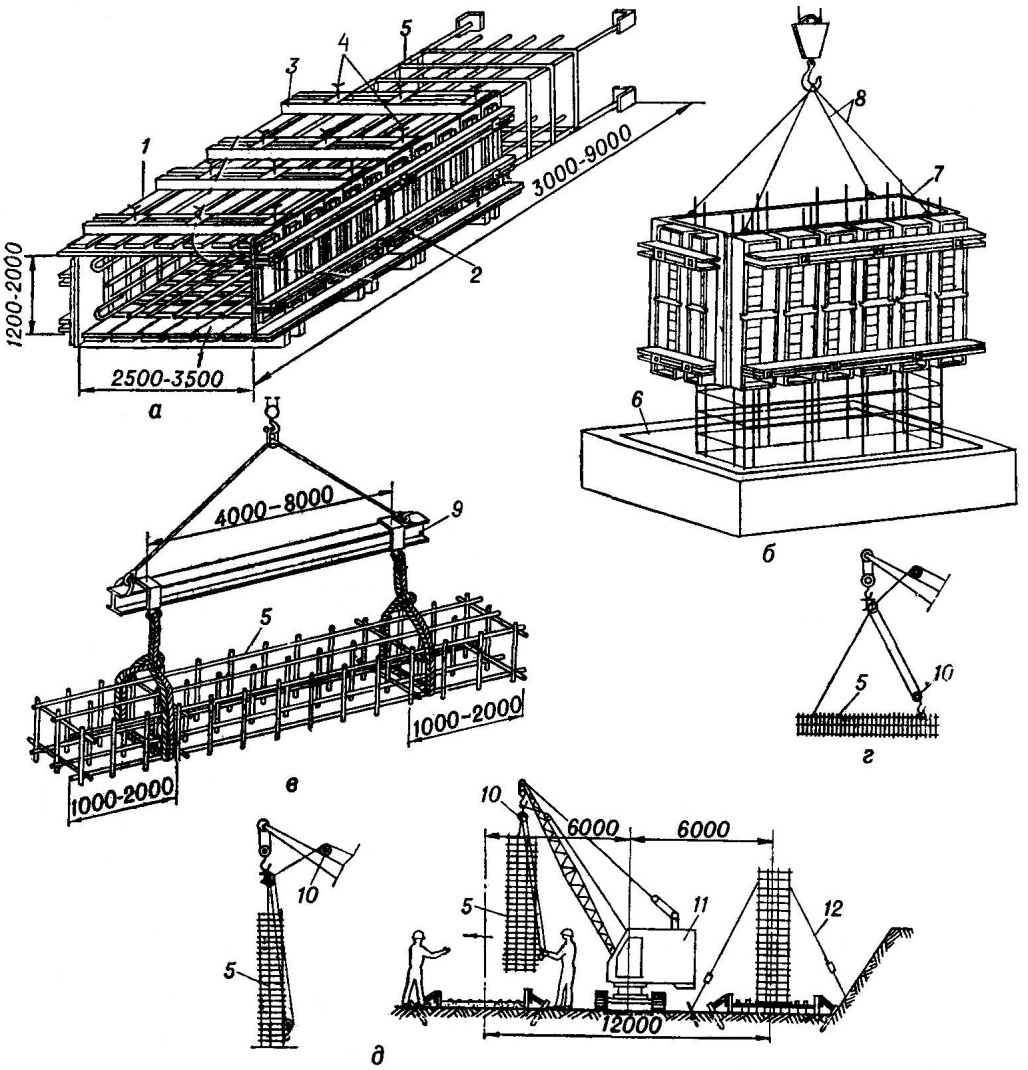

Figure: 1.2. Large-scale assembly schemes for small-panel formwork:

a - into large-panel formwork panels; b, c - in spatial blocks; 1 - shield; 2 - horizontal run-scrum; 3 - the same, vertical; 4 - mounting loop; 5 - mounting traverse; 6 - tie-bar; 7 - clamp; 8 - scaffolds; 9 - fence

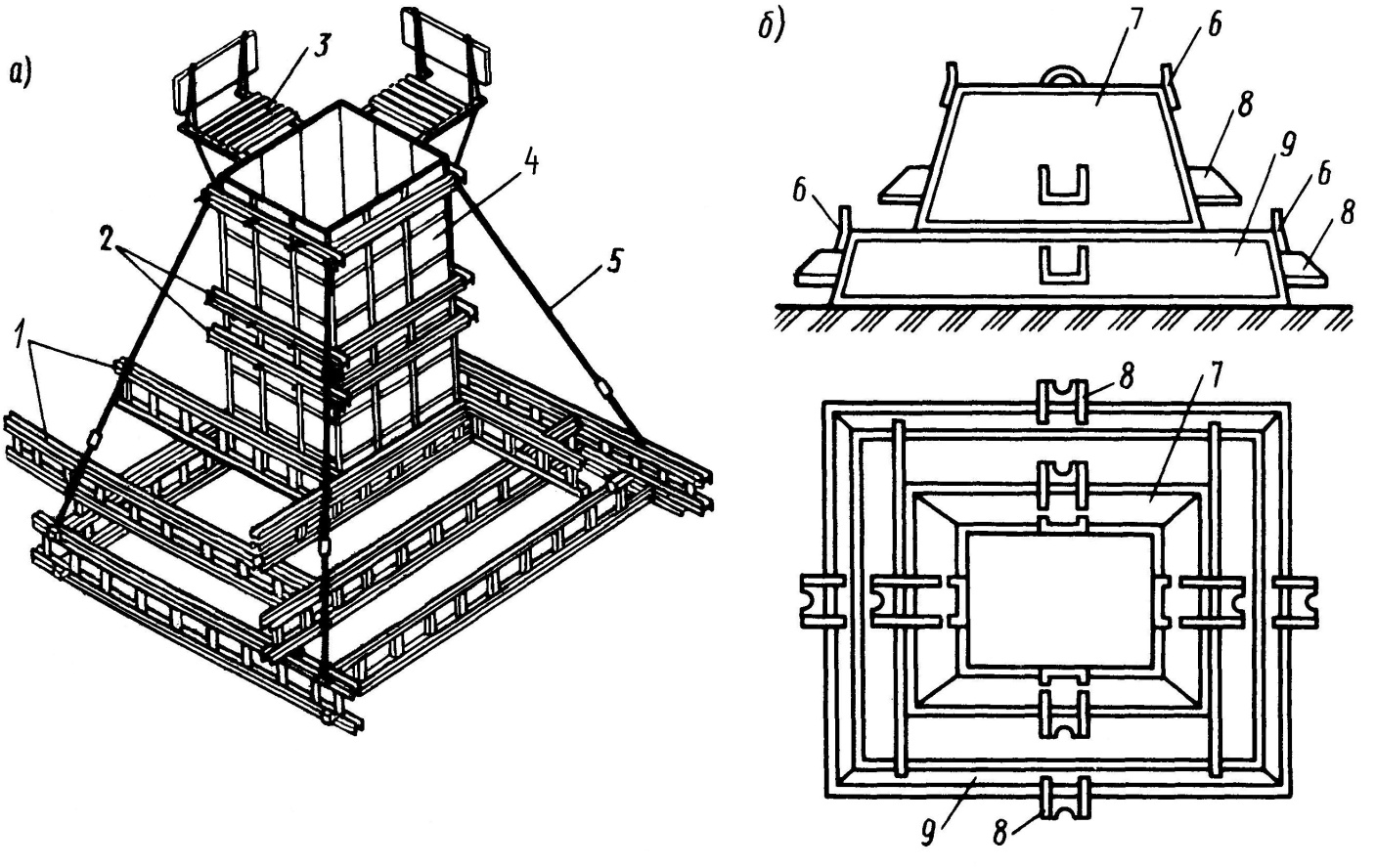

In industrial construction, during the mass construction of columnar stepped foundations, various block forms are used, which perform a rigid structure. Surfaces (planes) in contact with concrete are tapering to facilitate mold removal. Jacks are also used to detach forms from concrete.

When installing and fixing reinforcing cages in block formwork, reinforcing-formwork blocks are obtained.

Figure: 1.3. Large-panel formwork scheme:

a - general view (fragment of wall formwork); b - formwork panel; 1 - shield; 2, 10 - shield run; 3 - tie-bar; 4 - nut; 5 - scaffolds; 6 - brace; 7 - jack; 8 - shield edge; 9 - shield deck

Figure 1.4. Block formwork:

a - universal (readjustable) formwork block; b - block form; 1 - bearing trusses; 2 - contractions; 3 - working platform; 4 - shields; 5 - brace; 6 - mounting loops; 7 - the shape of the columnar; 8 - bracket for supporting jacks; 9 - step shape

Formwork device for strip foundations

When installing strip foundations, inventory shields are connected to each other with bolts, spring brackets, pins. The shields are attached to the inventory racks using tension hooks. The contractions of the opposing panels are fastened together with straps with screw or wedge locks. Contractions are used to perceive lateral pressure from the concrete mix. The required wall thickness is fixed with tie-rods or temporary struts.

Formwork device for columnar stepped foundations

The formwork of columnar stepped foundations is mounted in enlarged blocks. Dismountable blocks are assembled from shields, corner elements and fights. The blocks are assembled in the following sequence:

Formwork panels are enlarged into panels. For this, the shields are laid out with the working planes downward according to the assembly scheme and connected to each other with bolts, spring brackets;

Then, scrapes are installed on the panels, to which the formwork panels are attached with tension hooks. If necessary, stiffening ties are installed and fastened with 24 mm W bolts;

Panels are combined into a spatial block using corner elements and contractions.

Block-molds of individual production for concreting free-standing foundations are made one-piece, made on a cone and sliding.

Before use, the work surface is cleaned and an anti-adhesive lubricant is applied using a spray gun. Installation and dismantling of blocks is carried out with a crane.

Climbing formwork

Climbing formwork is used for the construction of structures of variable cross-section in height (factory pipes, cooling towers, etc.). The formwork consists of internal and external shields, bearing rings, a support frame, mechanisms for radial movement of the external formwork, a working platform for external and internal scaffolding. The external formwork is assembled from two types of panels, which are rectangular and trapezoidal. Rectangular shields have dimensions of 2700 × 850 mm, trapezoidal - 818 mm wide at the top, 850 mm at the bottom, 2700 mm high. The deck of the panels is made of steel sheet 2 mm thick and framed with corners. Trapezoidal shields ensure the taper of the erected structure. The sheets are connected to each other with bolts passed through the holes in the corners of the framing and a metal plate installed at the upper edge of the sheets.

In the outer formwork, there are also end sheets that close the formwork. To tighten the outer formwork at the locations of the end sheets, tie bolts are installed.

The internal formwork is assembled in two tiers from steel panels 1250 mm high, 550 mm wide and 2 mm thick. On the outer surface of the sheets, strips with brackets are welded, which serve to install spacer rods in them, providing rigidity and geometric invariability of the inner formwork. A horizontal bar with rings is attached to the upper edge of the shield for tying the rope when rearranging the shields. To connect adjacent boards in one tier, a metal plate is attached to the horizontal bar. When installing the upper shield on the lower extreme brackets overlap the horizontal bar. The inner formwork is closed with the help of terminal boards having one bar with brackets.

Outside formwork panels, a working platform are suspended from the bearing rings, and suspended scaffolding is also attached. With the help of radial movement mechanisms, the outer formwork is lifted, while changing the diameter of the concreted structure. The bearing rings are attached by means of hangers to the lifting head located on the mine hoist and designed to move the elements of the climbing formwork. Materials required for concreting are conveyed through a mine elevator. The average speed of concreting factory pipes is 1.2 - 1.5 m per day.

Sliding formwork

Sliding formwork is used in the construction of high-rise structures with a section that does not change in height (silos, cylindrical pipes, stiffening cores, high-rise buildings). Sliding formwork consists of formwork panels, U-shaped jack frames, jack rods, working platform and hanging scaffolds.

Formwork boards are usually made of metal-wood with a height of 1.1 - 1.2 m. The labor intensity of formwork is reduced by enlarging the formwork boards. To reduce the frictional forces when lifting the formwork, the shields are tapering with a broadening in the lower part by 10 - 12 mm. The inner surfaces of the boards are treated with a release agent.

Jack U-shaped frames and jack rods are load-bearing elements of the formwork. Jack frames are installed through jacks on jack rods. Jack rods are made of steel St 5 with a diameter of 25 - 32 mm, the distance between the rods depends on the lifting capacity of the jacks, the rigidity of the form, the location and dimensions of the openings and is usually equal to 1.5 - 2.0 m.

The flooring of the working platform is wooden, laid on metal purlins from bent profiles. The purlins are fixed to the racks of the U-shaped frames. If necessary, suspended scaffolds are fixed to them. Concreting defects are eliminated from suspended scaffolds and the concrete surface is rubbed.

The formwork is lifted using jacks resting on jack rods, which are installed inside the formwork of the structure being erected. The jacks, rising along the jack rods, carry along the U-shaped frames with the formwork and auxiliary devices suspended from them.

Recently, it is planned to increase the lifting capacity of the jacks to 10 tons and more, the diameter of the jack rods to 50 mm. This will increase the step between the jack frames, which will make it possible to mount reinforcement with large-sized frames and meshes, as well as mechanize the supply of concrete.

For the construction of stiffening cores, elevators, silos in sliding formwork, the rodless method of concreting is used. With this method, the jack rods are replaced by screw rods located outside the concrete structure. The rigidity of the formwork is provided by the upper and lower support rings. Application of this method allows to reduce the consumption of reinforcement, reduce labor intensity by eliminating welding and alignment of jack rods. From the bottom, extreme brackets overlap the horizontal bar, the metal plate is not attached. external formwork, works

Volume-shifting formwork

Volumetric movable formwork is used for the construction of high-rise, extended buildings with monolithic internal walls and ceilings. Formwork can be horizontally movable (tunnel) and vertically movable.

The horizontally movable formwork is used with the simultaneous construction of walls and floors. It consists of spatial U-shaped frames, from which the formwork block is assembled to the width of the building. The side surfaces of the frame serve as the formwork of the internal monolithic walls, and the upper one serves as the floor deck. The assembled formwork is set to the design position using a crane. After concreting and setting the stripping strength with concrete, the formwork is dismantled - the floor formwork is lowered with the help of jacks and the side surfaces are torn off the walls. Then the formwork is moved along inventory tracks laid along the floor to an adjacent position or special scaffolding. The scaffolds are arranged on the longitudinal side of the building. From the scaffold, the formwork is moved to the next floor.

A type of volumetric-movable formwork for horizontal movement is a formwork made of L-shaped panels. The panels are connected by adjustable struts and a central insert. To align the movement of the shields, screw jacks and hinge mechanisms are used. In this formwork, walls are concreted with a floor height of 2.8 and 3.0 m, and a wall pitch from 2.7 to 6.6 m.

When using vertically movable formwork, the floors are precast-monolithic or prefabricated. The formwork consists of a supporting frame with hinged shuttering boards fixed on it. The formwork is moved to the next position by a crane.

Rolling formwork

Rolling formwork is used in the construction of structures of linearly extended structures of constant and variable sections. The structures of horizontally movable formwork allow to move the formwork panels along the axis of the structure to be concreted, to raise the panels vertically for tier concreting, to adjust the slope of the surface of the concreted structures.

The formwork for the construction of walls is a spatial frame consisting of racks, two trolleys, a connecting beam and metal formwork panels. The shields are placed between the guide posts, which fix the position of the shields, perceive the pressure of the concrete mixture and transfer the forces from the horizontal movement mechanism - the shields. The shields are moved vertically by an electric winch mounted on the upper beam. Outrigger consoles on boards with a deck and fencing serve as working scaffolds. To receive the concrete mix, a receiving hopper with a vibrator is installed on the scaffolds.

Along the wall being erected, the formwork is moved along the rail track from an autonomous mechanical drive or an electric winch installed at the end of the section to be concreted.

Formwork-facing

Fixed formwork, depending on the purpose, is used:

Reinforced concrete - when erecting foundations of industrial buildings, technological equipment, when laying technological tunnels;

Expanded polystyrene blocks - as thermal insulation for the outer walls of residential buildings;

Asbestos-cement and metal formwork - they act as waterproofing.

The cladding formwork is attached to the main structure using anchoring loop-outlets, wire Ш 3 - 5 mm, embedded parts, and also gives the slabs a rough surface. Reinforced concrete formwork works in conjunction with monolithic concrete and is included in the design section of the structure.

2 Reinforcement work

Reinforcement works consist of a prefabricated reinforcement in the factory and its installation at the construction site.

Reinforcing steel with a diameter of 3 to 90 mm, hot-rolled and cold-drawn, wire, classes AI, A-II, A-III, A-IV are delivered to the construction site in the form of separate rods, 10 mm in diameter - in coils weighing 80-100 kg, coiled nets weighing up to 150 kg - made of wire Ш 3.0 - 3.5 mm.

Reinforcing steel, embedded parts and anchors arriving at the construction site are subjected to external inspection and measurements during acceptance. In the absence of the necessary data in the certificates of the manufacturers, they are subjected to control tests. The selection procedure, test methods and the number of control samples are taken in accordance with GOSTs, technical specifications, as well as additional project instructions.

Reinforcement types:

a - flat mesh; b, c - flat frames; d - space frame; d - frame of T-section; e - the same, I-section; g - curved frame; h - cylindrical frame; and - knitted frame with bent rods; 1 - end hooks; 2 - lower working rods; 3 - working rods with bends; 4 - clamps

According to the complexity of installation, the reinforcement is divided into heavy - with a diameter of more than 12 mm and light - with a diameter of less than 12 mm.

The fittings are flexible and rigid. Flexible reinforcement - smooth and periodic profile. Reinforcement bars are more economical. Rigid reinforcement is made of rolled profiles - channels, I-beams, angles. It is allowed to attach formwork to rigid reinforcement.

Installation of stress-free fittings

Reinforcement of structures is performed with separate rods, flat and volumetric frames, meshes. Reinforcement cages and nets are made in conductors that ensure the exact location of the elements to be welded. Load-bearing reinforcing cages using rods with a diameter of more than 32 mm must be manufactured taking into account the requirements for the manufacture, installation and acceptance of metal structures.

Places for slinging reinforcement products should be marked in accordance with the working drawings. When installing valves, the following requirements must be observed:

Before installing the reinforcement, the formwork must be checked;

The reinforcement should be installed in a sequence that ensures its correct position and fastening, as well as the required thickness of the concrete cover;

The required thickness of the protective concrete layer is provided by installing concrete, plastic and metal clamps;

The assembled reinforcement must be secured against displacement and protected from damage that may occur during the process of concreting the structure.

The displacement of reinforcing bars of cages and meshes should not exceed 1/5 of the largest diameter of the bar and 1/4 of the diameter of the bar to be installed. Butt joints of reinforcement are performed by resistance butt and spot welding, semi-automatic submerged arc welding and flux-cored wire in inventory forms, single-electrode or multi-electrode arc bath welding in inventory forms. It is allowed to weld butt joints with an arc bath, electrode or bath-seam welding with the remaining steel pads or pads, semi-automatic and single-electrode arc welding with multilayer seams, arc welding with extended seams with paired pads or overlapping.

Lap joints without welding are used when reinforcing structures with welded meshes or flat frames with one-sided arrangement of working reinforcement rods and with a reinforcement diameter not exceeding 32 mm. The amount of overlap (bypass) is established by SNiP, depending on the nature of the element, the location of the joint, the class of concrete and reinforcing steel.

When joining welded meshes of round smooth rods, at least two transverse rods should be placed within the joint.

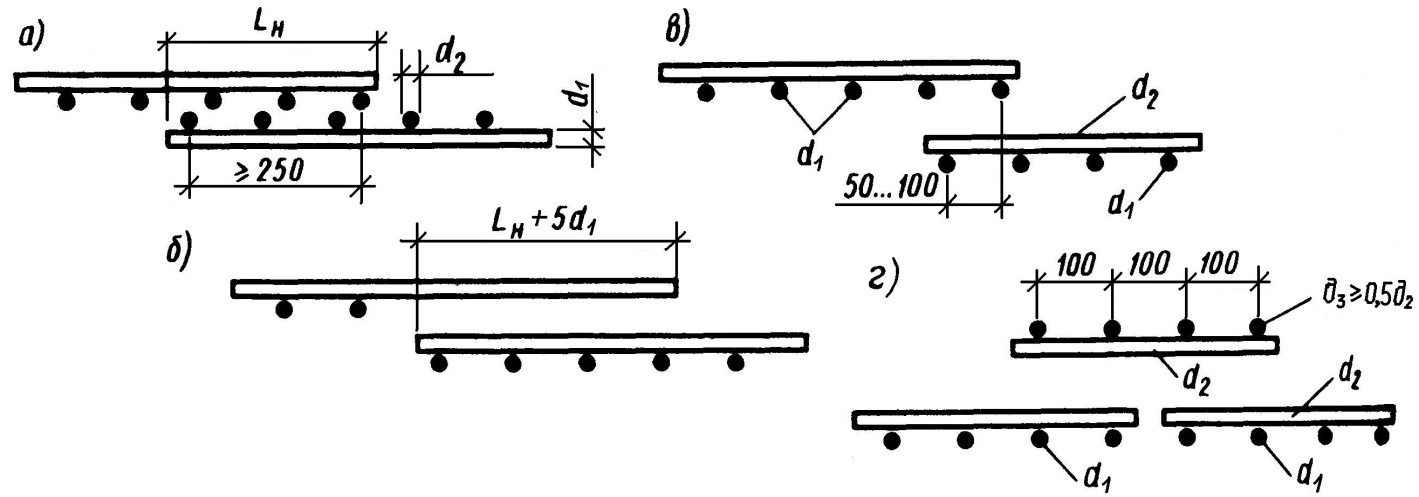

Figure: 2.1. Overlapping welded mesh:

a - from rods of a smooth profile with an overlap; b - the same, periodic profile; c - the same, in a non-working direction with a bypass; d - the same, with an additional mesh; d1 is the diameter of the working rods; d2 is the diameter of the distribution rods; d3 - diameter of the additional mesh distribution rods

When joining meshes made of rods of a periodic profile, it is not necessary to weld transverse rods within the joint, but the length of the overlap in this case is increased by five diameters (see Fig. 2.1, b).

The joints of the rods in the non-working direction (transverse mounting rods) are performed with a bypass of 50 mm with a diameter of distribution rods up to 4 mm, and 100 mm with a diameter of more than 4 mm (see Fig. 2.1, c).

With a working reinforcement diameter of 26 mm or more, it is recommended to lay welded nets in the non-working direction close to each other, overlapping the joint with special butt nets with a bypass in each direction of at least 15 diameters of distribution reinforcement, but not less than 100 mm.

The assembled reinforcement is taken before the concrete mixture is laid and an act of inspection of hidden works is drawn up.

Stress reinforcement of structures

The tensioned reinforcing elements are harvested on technological lines. High-strength wire and reinforcing ropes are cut with mechanical shears or friction circular saws. Cutting them with an electric arc is not allowed. For bar reinforcement, hot-rolled steel of periodic profile of classes A-II, A-IIIв, A-IVн, At-IV, A-V, At-V, At-VI and high-strength wire B-II and Bp-II are used.

Prestressing in monolithic and precast-monolithic structures is performed on hardened concrete.

According to the method of laying prestressing reinforcement, there are linear and continuous methods. With the linear method, channels are left in prestressed structures during concreting. After the concrete has acquired a given strength, reinforcement is placed in the channels and its tension is made with the transfer of forces to the concrete of the structure. The linear method is used in the manufacture of beams, columns, frames, pipes, silos, etc.

The continuous method provides for winding with a given tension of an endless reinforcing wire along the contour of a concreted structure. The method is used for prestressing the walls of cylindrical tanks, gas tanks, sedimentation tanks, etc.

When tensioning reinforcement onto concrete of a structure, the following conditions must be observed:

The strength of the concrete of the structure and joints must not be lower than that established by the project, which must be confirmed by the results of testing control samples;

The actual dimensions of the structure must correspond to the design;

The concrete of the structure should be free of cavities, cracks and other defects that weaken the bearing capacity;

The structure to be crimped must rest in the places indicated in the project, and the supporting nodes must have freedom of movement;

In the places where anchors and jacks are installed, the concrete surface should be flat and perpendicular to the direction of the reinforcement; during installation, anchors and jacks must be centered along the axis of the reinforcement while maintaining this position during the tension period;

The stretched reinforcement must be injected, concreted or covered with anti-corrosion compounds provided for by the project, within the time frame excluding its corrosion.

In structures with a straight channel length of less than 18 m, the reinforcement is tensioned from one side. First, the reinforcement is tensioned with a force equal to 0.1 of the design force, at which the stress elements are straightened and tightly adhered to the concrete surface. An effort equal to 0.1 of the calculated one is taken as a zero reading during further control of the tension by the pressure gauge and deformations.

With the length of rectilinear channels more than 18 m and curved channels, the reinforcement is pulled from both sides of the structure.

The canals are injected with a solution of at least M 300 on cement of grades M 400, M 500 and washed sand. The canals are injected immediately after tensioning the reinforcement and are carried out continuously under a pressure of 0.1 MPa to 0.4 MPa. Stop pumping after the solution starts to flow out from the other side of the channel.

With channelless stress, the reinforcement is covered with an anti-corrosion compound, and then with fluoroplastic (Teflon), which has an almost zero coefficient of friction. When pulled, the rope slides relatively easily in the concrete body.

Reinforcement of the soles of columnar foundations

Reinforcement of the soles of columnar foundations is carried out with welded, steel, unified nets. The meshes are made in reinforcement shops.

Figure: 2.2. Reinforcement of the soles of foundations

Figure: 2.3. Concrete cover formation

The thickness of the concrete cover in the foundations must be at least 70 mm in the absence of concrete preparation and at least 35 mm in the presence of concrete preparation. For concrete preparation, concrete of class B 5 is used, for the foundation - B 12.5 (grade M 150, M 200

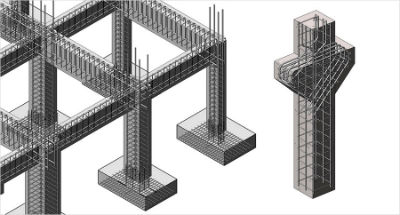

Column reinforcement

Reinforcement of columns is carried out with spatial and flat reinforcement frames, separate rods.

Reinforcement cages weighing more than 100 kg are fed and installed in the design position using a crane. Slinging of frames is carried out with semi-automatic slings.

Figure: 2.4. Installation diagrams of reinforcement-formwork and reinforcement blocks:

a - general view of the reinforcement-formwork block of the sub-column; b - installation of this block; c - installation of the strip foundation reinforcement block; d, d - the same, columns; 1 - formwork panels; 2, 3 - contractions; 4 - fastening bolts; 5 - valve block; 6 - glass of the foundation; 7 - reinforcing and formwork block; 8 - slings; 9 - traverse; 10 - semi-automatic sling; 11 - crawler crane

Light column frames are manually installed in a formwork box, open on one side. The frame rods are seized by electric welding with the release of the reinforcement. After releasing the crane hook, the design fastening of the rods to the outlets or embedded parts is performed.

When reinforcing with flat frames, they are connected by welding at the installation site into spatial ones.

If the reinforcement of the columns is knitted in place from separate rods, then the outlets of the reinforcement of the underlying structures are straightened, the vertical rods are tied to them and fastened with clamps. The rods are fastened with knitting wire between themselves and with clamps.

Reinforcement of beams, purlins, crossbars

Reinforcement of beams, girders, girders is carried out with volumetric and flat frames. Heavy frames are lifted and erected with cranes, light ones manually. The ends of the frames are wound up behind the column reinforcement outlets and attached to them. Flat welded frames are alternately lowered into the formwork and fixed in the desired position by welding the transverse rods.

Reinforcement of floor slabs, coatings

Reinforcement of floor slabs, coatings are performed after the installation of reinforcing cages of beams and girders. Reinforcement of the slabs consists in rolling out rolled nets along the formwork, which are fixed in the design position according to the markings made on the formwork. With double reinforcement of slabs, fixing the position of the upper meshes is made with reinforcing steel hinges.

Figure: 2.5. Scheme for fixing the position of the upper nets and ensuring the thickness of the protective layer

Reinforcement of floors, coverings with profiled sheet steel

Application of profiled metal decking:

Combines the functions of permanent formwork and working reinforcement;

Allows to exclude such labor-intensive processes as the device and dismantling of the formwork;

Reduce metal consumption for reinforcement;

Improve the aesthetic perception of structures.

Figure: 2.6. An example of a permanent formwork:

1 - monolithic concrete slab; 2 - profiled steel deck; 3 - bent plate anchors; 4 - spot welding

The use of flooring allows to reduce the labor intensity of work by 0.24 man-hours / m2.

To increase the connection of the flooring with concrete, anchors are welded, additional corrugations and dents are stamped.

Dents are arranged with a depth of 4 - 5 mm with a step of 150 mm.

Anchors are made of sheet metal 1.0 mm thick, with a height equal to 1/2 of the corrugation height. The anchors are fastened to the deck by spot welding.

Quality control of works and acceptance of mounted fittings

Reinforcement work is a hidden work. Each deviation from the project - replacement of the diameters of the reinforcement, its relative position - must be fixed by an act.

Before concreting, all mounted reinforcing structures are inspected, their dimensions are checked for design. At the same time, the location, diameter and number of rods, the distance between them, the correctness of the joints, the position of the pads to form a protective layer are checked.

Weld seams and assemblies made during installation are controlled by random tests of samples. To test the strength of welded joints, 3 samples are taken from each batch. Welded joints made by resistance butt welding, when tested for strength, must withstand loads corresponding to the ultimate tensile strength of a given class of steel.

3 Installation of building structures

Installation of structures is an industrial, mechanized, complex process of erecting buildings and structures from prefabricated structures and elements manufactured in a factory.

Installation of building structures includes the implementation of transport, preparatory and assembly processes. Transport processes are associated with horizontal and vertical movement of structures and consist of loading, delivery, acceptance, unloading and storage of structures.

The preparatory processes include: making grippers, checking the correctness of the foundation, pre-assembly, reinforcement before lifting. The actual assembly processes consist of slinging, lifting, installation, temporary fastening, alignment, permanent fastening and protection of embedded parts from corrosion.

Site preparation for installation work

Before starting the installation of structures, the following must be completed:

Backfilling of soil after installation of foundations, laying of underground structures;

Foundations for assembled structures of the entire building;

Roads for movement and operation of vehicles and crane tracks for assembly mechanisms;

Areas for temporary storage and pre-assembly of structures.

There should also be:

Sources of energy and water were supplied to the places of their consumption, lighting of the assembly site was arranged;

Mounting mechanisms, mounting devices, tools are prepared for operation;

Technical documentation developed and approved.

Incoming control. During the incoming inspection, they check the availability of documents on the structure (passports, quality certificates, etc.), the compliance of the geometric parameters of the structures with the design ones, the completeness of all embedded, fixing, fastening and slinging devices, the compliance of the strength properties of the material of structures with the requirements of standards and the project.

Mounting accessories

Mounting devices should ensure fast slinging and unstitching of structures, performance of operations related to the installation and alignment of mounted structures, stability of structures before their design fixation.

Limiting and adjusting devices of mounting devices must ensure the specified accuracy of alignment of structures.

The weight of manual installation devices should not exceed: struts, guy wires and ties with a length of up to 3 m - 18 kg, with a length of up to 6 m - 35 kg; spacers - 5 kg; clamps - 7 kg; conductors - 50 kg. The mass of individual parts of mounting devices, assembled manually at the site of installation of structures, should not exceed 20 kg, and the length should be 6 m.

When a steel rope bends around the elements of mounting devices, the ratio of the diameter of the bending element to the diameter of the rope must be at least four. In this case, splicing of the rope is not allowed.

Mounting devices are made in a climatic version according to the conditions of regions with moderate and cold climates.

Structural erection methods

Methods for assembling structures are fundamental, characteristic solutions that determine the technical policy in the production of installation work.

By the enlargement of the mounted structures, they distinguish element-by-element, block and installation by whole structures. With element-by-element installation, the structures are installed one on top of the other. They are widely used in the installation of reinforced concrete structures.

The block installation method provides for the enlargement of structures into flat or spatial blocks of full or incomplete technological readiness. In blocks of full technological readiness, all types of

Similar abstracts:

Technological process of formwork for the construction of walls, columns and ceilings. Development of a construction schedule. Determination of labor and machine capacity of work. Calculation of the need for construction in temporary buildings and structures.

Description of the design of the main elements of the KUB-2.5 precast-monolithic system - floor panels, multi-storey columns, staircases, ventilation blocks, external wall panels, truss system; their installation. Rules for monolithing joints.

Description of the necessary equipment and the project for the construction of an industrial five-story building. Selection and justification of production methods and technical means. Technology and organization of production of bored piles. Concrete stripping and maintenance.

Designing the production of earthworks. Determination of the composition of processes and initial data. Counting the volume of earthworks. Organization and technology of earthworks. Selection of the leading machine for the excavation. Calculation of operational performance.

Determination of the dimensions of the pit for the building. Calculation of the volume of soil of the cut off vegetation layer and the soil developed in the excavation by an excavator, the volume of soil when cleaning the bottom of the excavation and making trenches for entry. Calculation of labor costs.

Conditions for the construction of a twelve-story residential frame building in Smolensk. Preparation of precast reinforced concrete structures, monolithic pile and grillage foundations, hollow-core slabs, curtain wall panels.

The main direction of technical policy in the field of improving technologies for the production of construction and installation works. Monolithic concrete construction. Calculation of the scope of work. The choice of the assembly crane. Organization and technology of the construction process.

Installation diagrams for multi-storey columns using a set of individual assembly equipment. Installation of internal walls, stiffening diaphragms in a frame building. Installation of a girder-free stiffening panel. Laying tie and ordinary floor slabs.

The technique of reinforcing beams with prestressed flexible elements, the stages of its implementation and the equipment used. Carrying out installation work when hanging structures. Restoration and waterproofing device. Preparation of concrete mix.

Prefabricated slabs with a longitudinal arrangement of reinforced concrete monolithic beams and columns in a two-storey administrative building: layout, calculation and design; determination of standard and design loads, choice of material, its characteristics.

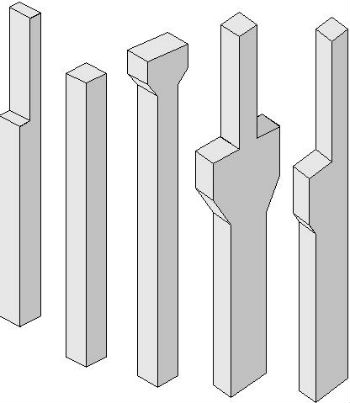

For columns and racks operating in central compression, a square section, sometimes rectangular, circular or annular, is generally accepted.

If the eccentricity is large (usually with eccentric compression), the cross-section of the columns is assumed to be rectangular. In this case, the large sides of the rectangle are located parallel to the axis relative to which there is an eccentricity.

Also, sections can be T-shaped or I-beams.

For the purpose of standardization, rectangular and square sections of columns are taken as multiples of 50 mm.

Concrete for columns is used not lower than B15 (C12 / 15), and for very loaded ones not lower than B25 (C20 / 25).

Columns are reinforced with longitudinal bars of reinforcement with a diameter of ≥ 12 mm made of steel of class A400C or A500C and transverse bars or clamps made of steel of class A240C

The dimensions of the cross-sections should be taken such that the flexibility l0 / r relative to any of the axes of the cross-section does not exceed 120.

The thickness of the concrete cover should be taken as ≥ the diameter of the longitudinal reinforcement bars and at least 20 mm. If strip, angle or shaped steel (in columns with a rigid frame) is used as longitudinal reinforcement, the thickness of the protective layer is taken as ≥50 mm;

Light distance between vertical rods reinforcement placed vertically during concreting must be ≥ 50 mm. The distance between the bars of the longitudinal reinforcement, located horizontally or at an angle during concreting, is taken ≥ 25 m for the reinforcement of the lower part of the section and ≥ 30 mm for the reinforcement of the upper part of the section. In addition, this distance is taken in all cases ≥ the largest diameter of the reinforcement;

Cross bars or clamps are installed without calculation, but subject to the following requirements:

If the column cross-section width is ≤ 400 mm and the number of longitudinal bars is ≤ 4, flat welded frames are designed without additional bars or single clamps;

For a cross-sectional width\u003e 400 mm or a number of longitudinal bars\u003e 4, additional bars are installed on one side or double clamps are installed; - instead of double clamps, it is allowed to install connecting pins;

Bendings of the clamps are provided at distances ≤ 400 mm along the width of the element cross-section.

The design of the knitted collars of the columns should be such that the longitudinal rods (at least through one) are located at the bend points of the collars, and these bends - at a distance of no more than 400 mm along the width of the column section. If the width of the edge is not more than 400 mm and the number of longitudinal bars at this edge is not more than four, it is allowed to cover all the longitudinal bars with one clamp.

The distance between transverse reinforcement bars is taken ≤ 15 d for knitted frames and ≤ 20 d for welded frames to prevent lateral buckling of longitudinal reinforcement bars. Moreover, in all cases, this distance is taken ≤ 500 mm, where d is the smallest of the diameters of the longitudinal compressed rods.

In columns with a longitudinal reinforcement coefficient of\u003e 3%, cross bars or stirrups are placed at distances ≤ 10d and ≤ 300 mm.

The diameter of the transverse reinforcement in welded cages is taken:

5-6 mm - with d \u003d 14-20 mm of longitudinal rods;

8 mm - with d \u003d 22-25 mm;

10 mm - with d \u003d 28-32 mm;

12 mm - with d \u003d 36-40 mm;

In knitted frames, the diameter of the clamps is taken as ≥ 5 mm and ≥ 0.25d, in this case d is the largest diameter of the longitudinal reinforcement bars.

As a rule, in the manufacture of knitted frames, clamps from wire of class A240C with a diameter of 6-8 mm are used.

In this article, we will talk about different types reinforcement of structures and reveal some secrets of the reinforcement profession. There will also be simplified calculations, documentation descriptions, reinforcement schemes. In the article you will find practical advice and recommendations for the management reinforcement works.

Reinforcement types

Reinforcement is an integral part of the structure, the material of which provides for the transition from a liquid state to a solid state. This process is called setting or hardening. Reinforcement methods are distinguished:

- Dispersed - adding fiber fibers or metal shavings to a liquid solution. Provides rigidity and abrasion resistance to the monolithic area. Applied in the device of floors, screeds. Can be used in combination with the rod method.

- Rod - in the volume of concrete or mortar, a system of rods (mesh, frame) is included, which distributes the load within the structure. They are used for load-bearing and free-standing building elements.

- Layer (layer reinforcement) - a mesh is included in the layer of liquid solution or putty to give stability to the finishing layer. Used for finishing and repairing planes.

In this article, we will consider the reinforcement of structures using a frame and meshes.

Reinforcement of structures

The hardened concrete can withstand high compressive loads - up to 1000 kg / cm 2, but is unstable to fracture, rupture and tension. Moreover, its production is relatively inexpensive.

The reinforcing bar carries significant tensile loads, but is not resistant to compression and bending. In addition, the cost of production is high considering that it includes the cost of mining the metal.

Since any load-bearing structure is subject to combined loads, a material is needed that meets several requirements. The combination of rebars and concrete gives a combination of their properties. The result is reinforced concrete that is resistant to compression, bending and fracture.

Since all reinforced concrete products are conditionally subdivided into factory and local production, the fittings work in them in different ways. Most of the factory products are manufactured using prestressed reinforcement. Before placing concrete in a mold, the rods are pre-stretched (strained) with a special device. After hardening, the stress in the rods remains - the reinforcement, as it were, "presses" the entire element along them, which significantly improves the mechanical properties of the part. For example, a beam or slab with prestressed reinforcement can withstand higher bending loads (+ 40-60%) than conventional ones.

In high-rise buildings, the reinforcement cage serves as the basis for the entire structure. The rods move from one element to another, which makes them interconnected and gives the required rigidity to the building frame. This effect makes it possible to build skyscrapers on a relatively small area.

Reinforcement SNiP

In the construction of critical buildings and structures, the calculation of the cross-section and the number of rods is one of the main ones. Reinforcement standards are regulated by documents - SNiP 2.03.01-84 "Concrete and reinforced concrete structures" and the appendix to it "Reinforcement of elements of monolithic reinforced concrete buildings. Design Guide ". These documents describe in detail the calculations, tolerances and requirements for structures in which reinforcement is applied.

Operating conditions and requirements for the rods themselves are standardized by the document GOST 10884-94 "Steel for reinforced concrete structures".

Deep calculations are necessary in the construction of large and complex objects - high-rise buildings, bridges, towers, dams. To calculate the reinforcement of structures in private construction, it is enough to adhere to the basic rules that are relevant for all applications of reinforcement.

Reinforcement range

Another useful document is assortment. It contains all the possible characteristics of reinforcing products - the weight of a running meter and its dependence on the diameter, the cross-sectional area of \u200b\u200bthe bar and steel grade, and many others. This data is necessary for more complex calculations - monolithic floors, tanks or buildings with more than 3 floors.

Reinforcement class

As a rule, the most common brands and rod diameters are used privately. This set can be conventionally called the "optimal discharge". It includes rods with a diameter of 6 to 18 mm. Classes of valves of optimal discharge according to GOST 5781:

- A1 (A240). Smooth rod Ø 6-12 mm - in coils (bobbins, skeins), 12-40 mm - in rods (circle).

- A2 (A300). Has helical ribs. Diameter 10-12 mm - in coils, 12-40 mm - in rods.

- A3 (A400). The transverse ribs diverge "herringbone" from the longitudinal rib. Ø 6-12 mm - in coils, 12-40 mm - rods.

Other grades are rare - mainly in high-demand facilities, these products are made to order from higher quality steel.

There are only two types of concrete reinforcement in terms of construction - a flat mesh (can be bent) or a spatial frame. The mesh is used for recumbent slabs and screeds, the space frame is used for volumetric elements - beams, lintels, armored belts, columns, walls, etc. In this case, two grids arranged at a stable distance from each other already represent a frame (for example, a wall).

Reinforcement calculation

When the shape of the product (element) and its size have been determined, it remains small to determine the diameter and pitch of the frame cell. In construction with low requirements, it is optimal to use an effective system of adapted calculation. The principle of using reinforcement of different diameters is simple - the more load the element carries, the thicker the rods are needed.

Indicators of frames and meshes for different structures:

| Item name | Rebar brand | Rod diameter, mm | Cell pitch, mm | Note |

| Concrete, blind area | A1, A2, A3 | 8 | 150-250 | Unloaded areas |

| Reclining plate, recumbent beam (armopoyas) | A2, A3 | 12-16 | 150-200 | No deeper than 50 mm from the top of the plate |

| Foundation beam, hanging beam, hanging plate | A3 | 16-18 | 100-160 | Depending on the presence of reinforcements and attachment points, load |

| Column, thrust wall | A3 | 14-18 | 100-160 | Depends on applied load |

| Sideboard | A2, A3 | 12-16 | 120-160 | No significant load |

| Building wall | A3 | 16 | 100-160 | Depending on the binding |

In the adapted calculation, the general principle can be applied - a sufficient cell pitch will be equal to the diameter of the bar multiplied by 10. In critical places - abutments and connections of elements - reinforcements should be added, that is, additional rods should be installed.

Reinforcement scheme

As a rule, two types of elements are arranged from reinforced concrete - beams and slabs. In 80% of cases, two positions will be enough to complete a frame of any complexity:

- working rods - reinforcement rods Ø 12-18 mm, arranged along the structure;

- distribution (structural) elements - products made of wire Ø 6-8 mm, which are distributed in space and fix the working rods with a given pitch.

Of course, knitting wire is needed.

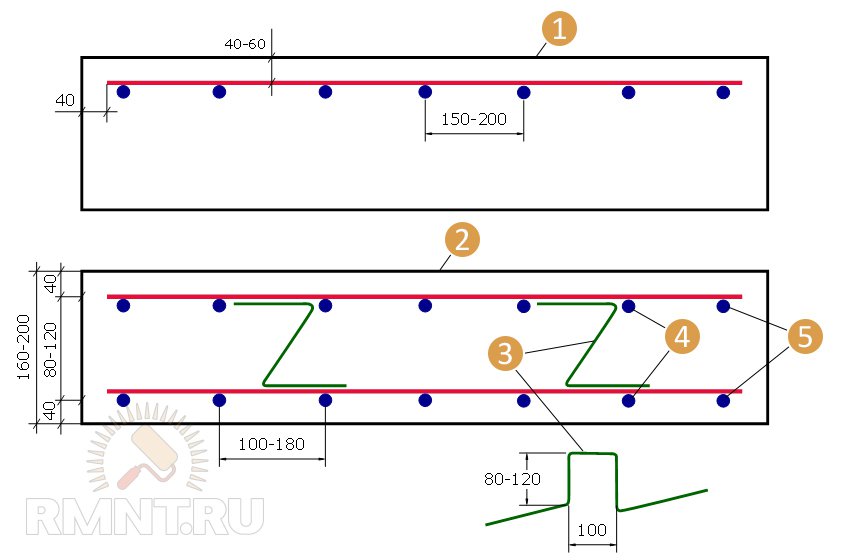

Beam reinforcement scheme: 1 - reinforcement of recumbent, foundation beams and armored belt; 2 - reinforcement of hanging beams, foundation; 3 - protective layer 40 mm; 4 - auxiliary working rods; 5 - main working rods; 6 - clamp

Beam reinforcement scheme: 1 - reinforcement of recumbent, foundation beams and armored belt; 2 - reinforcement of hanging beams, foundation; 3 - protective layer 40 mm; 4 - auxiliary working rods; 5 - main working rods; 6 - clamp

If the beam is supposed to be hanging, all the bars in it must be of the same cross-section (at least 16 mm). For a recumbent beam, the auxiliary rods can be smaller in diameter.

Plate reinforcement scheme: 1 - recumbent plate; 2 - hanging plate; 3 - "frog"; 4 - distribution fittings; 5 - working fittings

Plate reinforcement scheme: 1 - recumbent plate; 2 - hanging plate; 3 - "frog"; 4 - distribution fittings; 5 - working fittings

The hanging slab frame consists of two mirrored meshes. The equal distance between them is kept with the help of stops.

Rebar machine

In order to make elements of the "clamp" or "frog" type, you will need a special device - a bending machine. If a tangible amount of concreting is expected, you should start with the manufacture of this machine from the material at hand. It is a workbench on a steel frame, securely installed in a horizontal position.

To assemble a machine for reinforcement in place, you will need an available material - metal trimmings, among which there should be two corners 40x40 or 45x45.

Work order:

- The main element of the machine is a stop with a sleeve. In the middle of the workbench, we weld a rod 8-10 mm long vertically and select a steel tube that can be easily put on it.

- We weld a lever to the tube - the best corner is a horizontal shelf to the tube. If there is no corner, then the stop is 100 mm from the welded rod.

- We weld a comfortable handle to the outer edge of the lever.

- We lay the reinforcement of the largest diameter (but not more than 18 mm), which must be bent parallel to the long edge of the workbench.

- We weld an emphasis to the workbench - a corner is best.

The machine can be of any design. The basic idea is that the force is applied at three points through the levers.

On sale you can often find factory hand tools for rebar bending, but they rarely withstand heavy loads and are intended for home use. For large volumes, you can purchase an electric bending machine 220 or 380 V. Using an electric machine, you can bend rather complex elements, which are also used in artistic forging. The price of a new electric bending machine up to 40 mm starts from 70,000 rubles.

Rebar welding

The most common mistake when performing reinforcement work is the use of electric welding to connect the frame elements. The reasons why this cannot be done:

- Overheating of the metal. Steel with a relatively high carbon content is used in the production of valves of classes A1, A2, A3. This means that after heating it loses up to 50% of its strength properties. This is especially important for angled connections.

- Incorrect load distribution. The rigidly fixed (welded) section of the rod is, as it were, isolated from it and works separately from the rest of it. For this reason, abnormal stresses arise, concentrated in the places of rigid fixation (welding) instead of being distributed along the entire length.

- An incorrectly assembled frame will only have to be thrown away (it is impossible to remake).

- Danger to other workers - Accidental electric shock possible.

- Electricity costs.

However, there are cases when welding is not only irreplaceable, but also required:

- Installation of embedded parts (ZD). ZD - priority elements on which a large load is concentrated. They are welded into the frame for better load transfer to the rods.

- Welding of longitudinal joints (overlaps). Overheated reinforcement retains up to 70% of its tensile properties. In addition, it is doubled on the overlap. Butt welding of longitudinal rods is meaningless.

- Fastening in place to the existing ST or steel elements (during the reconstruction of buildings).

Rebar knitting

Fastening intersecting rods to each other is a painstaking and time-consuming job. But it cannot be avoided when reinforcing structures. To do this, use a soft knitting wire thickness from 0.5 to 2.5 mm. The device for work - the hook of the fitter - each specialist chooses for himself. There is a small assortment of factory models, but in most cases the hook is made on site from a rod of wire Ø 8-12 mm. To do this, you need to bend it in a convenient shape and sharpen it at one end. You can put a plastic tube on the opposite end of the hook bar. Also, the hook can be installed in a cordless screwdriver, which will greatly facilitate the work.

To facilitate the work of the fitter, there are developed forms of a crochet hook:

- Factory reinforcement hook. A bearing is installed between the handle and the hook shaft.

- Automatic hook. It rotates due to the spring in the handle connected to the sting.

- Knitting device (gun). The operation is automated, the gun itself presses the rods and knits the wire.

When creating frames for different elements, a different knitting step is used. The more critical the site, the denser the nodes will be.

Step of nodes in different frames:

Reinforcement work often involves the installation of formwork, which is often oiled to facilitate dismantling. Be careful not to get oil on the rods - this will lead to a lack of adhesion between the concrete and the reinforcement. The use of highly oxidized fittings is categorically undesirable.

Vitaly Dolbinov, rmnt.ru

Columns are reinforced concrete load-bearing structures designed to transfer loads from higher structures to foundations or walls.

Columns are used on the floors, for installation on their capitals or consoles of higher floors. They also have a pillar support.

The most important point in the construction of columns is the calculation and arrangement of their reinforcement. Let's talk about him now.

1 Features and purpose

1.1 Construction

Consider the design of reinforced concrete columns in order to understand in the future what kind of diagram and drawing they need.

A drawing of any bearing support transferring loads to the foundation cavity shows that it consists of several basic parts. In particular, the scheme provides for the presence of:

- the main bearing part;

- capitals or consoles;

- podkolon.

Main part drawing - elongated rectangle, minimum size whose section is approximately equal to 150 × 150 mm. Maximum size sections are not limited to indicators of 500 × 500 mm, although it is reasonable to use the latter only when interacting with flat foundation structures.

At the top of the columns, there are capitals or consoles - these are supports for the floors... The capitals are protrusions on which the floors can be mounted. Such a scheme simplifies the work of builders, saves on materials, in particular, significantly reduces the use of beams.

However, capitals are used with the same success as a base for beams.

As for the reinforced concrete elements such as a sub-column, their scheme is an example of a conventional sole. The design of the standard sub-column resembles a stepped expansion under the column base. The task of the column column is to relieve point stress and evenly transfer it to the walls of the foundation.

The use of a sub-column is optional, it is quite possible to do without it when it is planned to install a strip or pile foundation. But for a tiled foundation, the presence of a sub-column is simply necessary.

1.2 Calculation

Before starting the analysis of the column reinforcement, you need to carefully examine the drawing and carry out the calculation. Calculation is the cornerstone of all such processes. The calculation allows a person to clearly determine what he needs, for what and in what quantities.

The standard calculation of a column provides for taking into account its bearing loads, the type of foundation, the presence or absence of additional elements (capitals of the column, etc.), the grade of concrete, etc.

After the calculation is completed, a drawing and a reinforcement diagram are drawn up. The drawing shows how much reinforcement is needed, what kind of reinforcement it should be, in what order it should be knittedwhat additional elements to use.

The calculation is performed using special formulas. They include the resistance of materials, the ratio of the level of ultimate loads to the desired, etc.

The calculation is carried out exclusively by specialists. A person without experience will not be able to design the reinforcement of bearing supports. Not enough knowledge, and more importantly, experience.

1.3 Percentage of reinforcement

For correct reinforcement, as we have already noted, you need a high-quality calculation and a correctly drawn up drawing or diagram.

Such an interesting indicator as the percentage of reinforcement or filling with reinforcement is also included in the calculation. The percentage of reinforcement indicates the specific gravity or proportion of the reinforcement cage in the overall structure.

There is a maximum and minimum percentage of reinforcement for reinforced concrete supports. The minimum percentage is the line below which you cannot go. If the reinforcement of reinforced concrete structures does not cover the minimum percentage, then the structure is considered unreliable and even potentially dangerous.

The maximum percentage is the limit after which the structure from reinforced concrete turns into steel-reinforced concrete. It is also undesirable to exceed the maximum percentage, especially in civil engineering.

The indicator, the minimum percentage of column reinforcement is 3%. The maximum percentage of reinforcement is 6%. However, the calculation shows that 5% is enough for small buildings, and in some cases 4% in specific gravity.

2 Technology, scheme and materials

Reinforcement technology is quite simple, as it includes only a few basic working steps.

It is necessary to create a reinforcing cage in stages, tie it into a single structure, if necessary, carry out transverse or indirect reinforcement, and then install it into the formwork. The main task of the builders is to tie the correct frame. The process is very simple here.

Several large round rods with a cross-sectional diameter of 20 mm or more are taken. As a rule, these are round bars, class A3 or higher.

The length of the rods must fully correspond to the length of the column, minus 10-15 cm per layer of protective concrete.

The minimum number of rods for a working frame is three. Which, however, is quite obvious, because we do not need a flat, but a volumetric frame.

In practice, four to six rods are used in conventional columns and more than eight in heavily loaded columns. If the column is not square, but elongated in one of the directions, then it is reinforced with additional reinforcement.

Longitudinal reinforcement is tied together in several places. However, it will not be possible to manage only with it. With a column length of 2 meters, longitudinal products under pressure will begin to protrude, which is not good. To prevent such problems, indirect or lateral strengthening of the frame is used.

Indirect reinforcement consists in tying long reinforcement with transverse short rods. Indirect reinforcement is done at intervals. It is desirable to tie the frame with transverse elements with an interval of 20-50 cm, depending on the level of bearing loads.

Indirect reinforcement is a time-tested method, very convenient and simple. Without it, the creation of load-bearing reinforced concrete columns is now highly undesirable.

2.1 An example of column reinforcement in construction (video)

2.2 Reinforcement of additional elements

Do not forget that the construction of additional parts of the column, such as capitals, consoles and support structures of the sub-column also need reinforcement.

In this case, the frame for the same capital must also be correctly integrated into the target supporting structure.

The example of a capital is a flat ledge at the top of a column. Therefore, a reinforcing mesh is needed for the frame of the capital. Everything is quite simple here. We take reinforcement with a thickness of 15 mm and more, and knit a square mesh from it with cells from 10 × 10 cm.

We integrate the mesh with the upper part of the frame by tying with wire. As a rule, a single-level grid is sufficient. In extreme cases, one more stabilizing frame is arranged along the rim, consisting of one or two elements.

With consoles, the situation is somewhat different. A console, unlike a capital, is a concrete ledge at one of the edges of the columns. The frame for it is a two-level protrusion of a short reinforcement attached to one of the transverse bars.

The sub-column scheme strongly resembles that of a monolithic capital, only the sub-column is made thicker, it can have several steps and is placed on the lower part of the support.

Consequently, the frame for it is made at least two-level, from the same mesh. Otherwise, there are practically no differences from the drawing of the frame for the capital.

If the sub-column is stepped, that is, it has several extensions with different sizes, then the mesh is made under each step and tied with wire. The more steps, the thinner the reinforcement is needed. Reinforcement with a thickness of 15-20 mm is taken for one step, and reinforcement with a thickness of up to 12 mm is enough for three.