In the construction industry, a lot of materials are used, many of which can be made decently. But for a novice entrepreneur who decides to occupy his own niche here, it is better to choose as the material produced, one that does not require huge investments and labor costs. And in this list, without a doubt, fiberglass reinforcement can be attributed. If you buy equipment for the production of composite reinforcement of proper quality, you can supply the market with products that are in demand by both large construction companies and private builders. Fiberglass (composite) reinforcement is a bundle of continuous glass fibers characterized by high strength. The thinnest threads here are connected by means of a special synthetic resin. Products can be used in the field of construction and decoration.

Our business valuation:

Starting investments - from 1300000 rubles.

Market saturation is average.

The complexity of starting a business is 6/10.

But despite the fact that the implementation of the idea does not require significant investment, it is necessary to carefully work out a business plan for the production of composite reinforcement, which will include the following items:

- Market and competition analysis.

- Technology for obtaining material.

- Workshop equipment.

- Financial justification of the project.

How is the production of composite reinforcement?

Technological scheme of production

The workshop for the production of composite reinforcement within its walls will process 2 main components:

- Bonding material (special mixture prepared on the basis of epoxy resin).

- Reinforcing material (roving).

In the finished product, the roving takes on all the mechanical load exerted on it, and the binder distributes it along the entire length of the rod.

It is impossible to designate at least any exact ratio of components - a lot depends on the purchased raw materials, temperature and humidity indicators in the workshop, the type and diameter of the manufactured reinforcement. And therefore, the final recipe will either have to be developed independently (if there is specific knowledge), or a specialist should be involved in the work. And the second option is more optimal here, since in the future the technologist will also monitor compliance with all modes in the process of manufacturing reinforcement.

Whatever raw materials are processed in the workshop, its strict incoming control should be organized, since the guarantee of the quality of the finished product is high-quality components from reliable suppliers.

The manufacture of composite reinforcement is a high-tech process that includes many physical and chemical reactions. But since all operations here are carried out with the help of special machines and devices, the technology for the production of composite reinforcement is quite simple:

- Fiberglass is impregnated with resin to form continuous lines.

- The roving is fed to a shaping die, at the output of which a rod of a given geometry and characteristics is obtained.

- The material is pulled under certain temperature indicators through the polymerization chamber.

- A "ribbing" is created on the rod.

The received products after the final stage are sent to warehouses for storage. Composite rebar can be stored in warehouses for a very long time, which is another advantage of the planned business - you do not have to worry about damage to products.

Technical equipment of the workshop

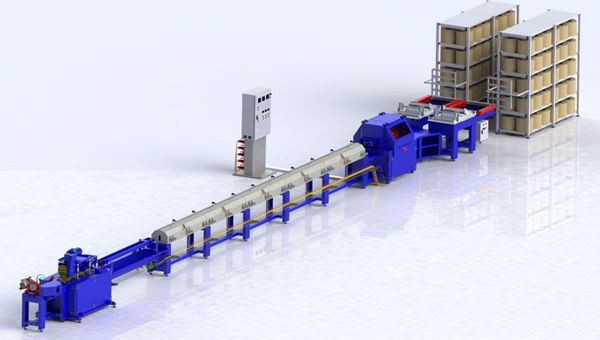

Composite Rebar Production Line

Mini plant for the production of composite reinforcement must be equipped with special automatic equipment. And its choice will depend on the planned sales volumes and available investments. And when choosing, you should not focus only on the cost of machines, it is better to prefer a proven manufacturer that supplies only high-quality machines and devices to the market.

The complete composite rebar production line is equipped with the following machines:

- creel for unwinding threads,

- yarn warmer machine

- soaking bath,

- filter set,

- wrapper,

- polarizing oven with the possibility of cooling products,

- stretching machine,

- rod cutting machine.

It is better for an entrepreneur to buy a line ready for work immediately, and not to equip the workshop with separate machines.

The price of equipment for composite reinforcement will depend on its functionality and power. On average, a good quality line that can produce products of different diameters costs 800,000-1,500,000 rubles. In the absence of such funds, you can think about purchasing used machines or renting them.

Requirements for a production facility

You can find a production facility in the industrial part of the city. Any empty building is suitable here, where water supply, sewerage and electricity can be provided. As for the area of the workshop itself, the machine for the production of medium-sized composite reinforcement can be placed on 50 m 2. But separately it will be necessary to allocate space for an office, staff rooms and storage facilities.

Mandatory requirements for the premises:

- Powerful ventilation.

- Temperature indicators - 16-18 ° С.

How profitable is the planned business?

The sale of composite reinforcement will only bring consistently high incomes when all manufactured products are shipped to customers. And therefore, we throw all our efforts into the search for wholesale customers.

The use of composite reinforcement is quite extensive, and its customers can be:

- Major developers.

- Companies specializing in interior decoration.

- Construction shops, bases and warehouses.

Selling finished products in bulk will bring a significantly higher profit. But here you should not bypass buyers from the niche of small businesses.

To indicate the profitability of the planned business, it is important to calculate the capital costs.

This may include:

- Registration of an enterprise - from 20,000 rubles.

- Purchase and commissioning of equipment - from 900,000 rubles.

- Preparation for the work of the premises - from 300,000 rubles.

- Purchase of raw materials for the production of the first batches of products - from 500,000 rubles.

It turns out that according to the most minimal estimates, the launch of the workshop will require ≈1,700,000 rubles. Costs can be reduced to 1,300,000 rubles if you buy a used production line.

The workshop of medium capacity produces up to 150,000 linear meters of finished products monthly. The current cost of composite reinforcement in the wholesale market is 6-10 rubles per linear meter. In this scenario, an entrepreneur can have revenue of up to 1,500,000 rubles per month. But it's still not a net profit. To get the figure we need, the variable costs that the composite reinforcement for the foundation will require during the manufacturing process should be subtracted from the revenue:

- purchase of raw materials,

- payment of taxes and wages to employees,

- transport and communication costs,

- communal payments.

As practice shows, a medium-sized workshop can bring its owner up to 100,000 rubles of net profit every month. It turns out that in less than 2 years it is quite possible to recoup all the investments invested in the launch of the enterprise. But these profitability figures are achievable only if the products are fully sold.