Concrete, although a durable material, is only resistant to certain types of loads. The constant compression that the foundation experiences under the weight of the house, and it tolerates compression in frozen soil perfectly. But it is worth applying multidirectional or simply uneven efforts, as cracks appear in the monolith, and it collapses.

Concrete is brittle and cannot bear bending or stretching on its own. To increase the resistance of concrete structures to just such loads, the foundation is reinforced with metal rods. The steel grating, assembled from rods and repeating the shape of the base, takes on the bending pressure, preventing the deformation of the concrete.

In the direction of the reinforcing rods, two types of reinforcement are distinguished:

- Horizontal - compensates for the loads that the weight of the building and the counter pressure of the soil exert on the base. Since the foundation surface assumes the maximum pressure, it is here that the thickest rods (10-16 mm) are needed.

- Vertical - reinforces the reinforcement of corners and those parts of the structure where lateral pressure prevails. It is also used in the installation of bored piles.

Naturally, the maximum effect is achieved only with the simultaneous use of these two methods. Reinforcement can be abandoned if construction is carried out on very strong coarse and rocky soils that are not prone to heaving. But in order to make such a decision, the technical justification must be correctly calculated. If this is not done, reinforcement cannot be excluded from the technology.

Strengthening different bases

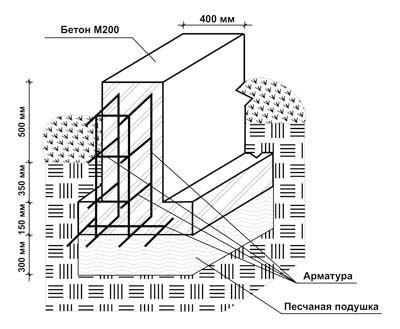

1. With a relatively small width, the strip foundation almost does not experience transverse loads, but longitudinal bending forces on long sections of the strip will certainly arise. Therefore, for it, vertical and transverse reinforcement can be made from rods of a smaller diameter (6-8 mm), but for longitudinal rods, it is necessary to correctly calculate. Their diameter will be in the range of 10-14 mm.

2. A pile or columnar foundation is completely undemanding to reinforcement - it is enough to use 1-4 corrugated bars with a cross section of 8-10 mm for it. The foundation, connected with a large-width reinforced concrete pad, experiences bending loads along its axis. To compensate for them, according to the instructions, additional transverse reinforcement should be laid in the lower part of the heel.

3. Monolithic slabs, resting on the ground with their entire plane, are unevenly loaded from above. As a result, the pressure on the concrete surface at all points of the foundation will be different, and in some cases the sum of the loads will even work to twist the slab. Here, equally thick reinforcement should be used for both longitudinal and transverse laying.

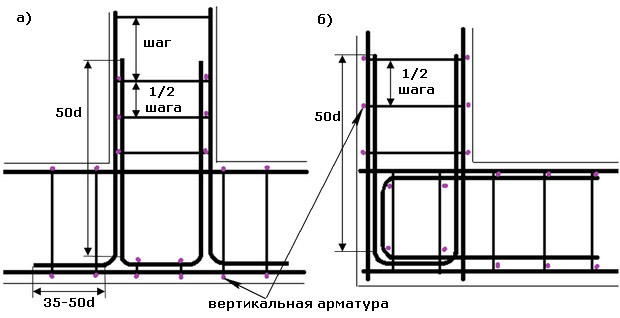

Particular attention is required to reinforce the corners of the strip foundation and junctions. At these points, there should be no conventional cross-connection of the longitudinal bars. Bent rods are laid in the corners, which are overlapped with those located on the straight sections of the concrete box.

It is strictly forbidden to bend the reinforcement with your own hands, making cuts in it or heating the bars yourself. For steel products, only cold bending technology is used.

Calculation features

The calculation of reinforcement for each foundation is performed separately, based on the schemes and geodetic data of a particular section. Only highly experienced professionals can afford to install the grid “by eye”, all the rest run the risk of making mistakes in the technology. Then, with a lack of reinforcement, the foundation will be short-lived, and with an excess of it, it will be too expensive.

Basic requirements for the design of the steel frame:

- The cell size is from 20 to 30 cm (2-3 times the size class of crushed stone in concrete).

- If the length of the section exceeds 3 m, the diameter of the products for longitudinal reinforcement is selected at least 12 mm.

- The transverse rods must be 100 mm shorter than the width of the formwork, so that 50 mm are left on the sides for pouring concrete. The diameter of the crossbars is not less than 6 mm or 8 - if the height of the frame exceeds 80 cm.

- Vertical bars are made shorter than the formwork height by the same 100 mm.

- All reinforcement overlaps are performed in a staggered way, that is, in the upper reinforcement zone, they should not be located above the connections of the lower mesh.

The density and reinforcement scheme is calculated based on the selected type of foundation and the conditions in which it will work. To make such a calculation yourself, you need to follow the instructions:

1. Select the class and appropriate size of steel reinforcement.

- For light wooden buildings on non-rocky soils, rods with a diameter of 10 mm are selected.

- Heavy houses on weak and moving soils are built on a foundation reinforced with 14-16 mm rods.

2. Determine the grid spacing (20 cm).

3. According to the dimensions of the foundation, calculate the number of rods for the upper and lower reinforcement belts.

4. The standard length of the rods is 6 m, therefore, multiplying their number by 6, we get the reinforcement consumption in linear meters. Here it is necessary to take into account the loss of length at the overlaps.

It is convenient to determine the amount of reinforcement with the simultaneous drawing up of a diagram of its location. Already at this stage, through the density of steel, you can calculate the weight and determine the price.

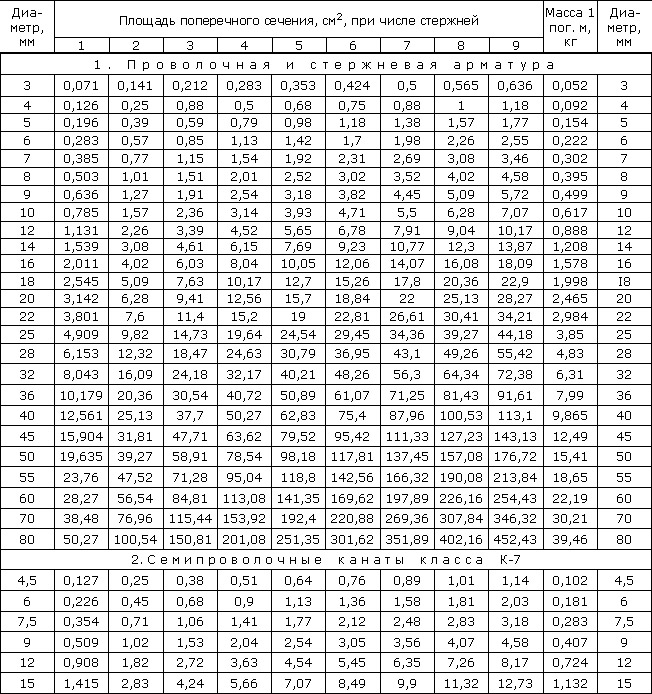

You can check how correctly the calculation was performed. According to the requirements of SNiP 52-01-2003, the total section of the reinforcement in the section must be greater than or equal to 0.1% of the area of the entire reinforced concrete structure in this plane. Based on this principle, it is easy to choose the appropriate reinforcement diameter for the foundation.

- The strip foundation has a cross section: 0.4 x 1 m or 4000 cm 2.

- The reinforcement area must be at least: 4000 × 0.001 = 4 cm 2.

We find the corresponding value in the table (there may be several of them) and determine the number and diameter of the rods:

In our example, these are 8 bars d = 8 mm, however, for laying it is more convenient to take rods with a small margin - 4 pieces of 12 mm each, in order to divide them into 2 strapping belts.

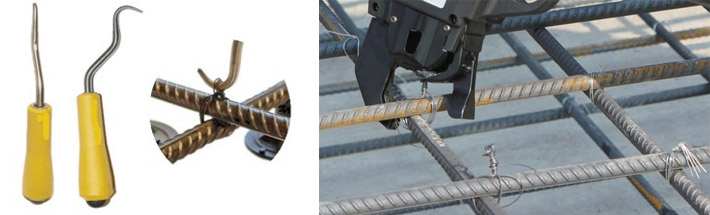

Wire laying technology

Do-it-yourself reinforcement of the strip foundation is carried out directly in the formwork prepared for pouring or nearby on a free site. The first method is the most reliable, as it allows you to control the correctness of the reinforcement. But the second one will be easier to do on your own.

Step-by-step instructions for assembling a steel frame:

1. Lay flat stones or bricks at the bottom of the trench for laying the longitudinal rods to raise them 5 cm above the surface.

2. From a smooth rod of a smaller diameter, make transverse jumpers with your own hands and lay them in increments of no more than 60 cm.

3. Fasten the vertical posts in the same way to the longitudinal reinforcement.

4. Tie the rods of the upper belt and fasten the transverse rods to them.

5. Lay the finished modules on the bottom of the trench and tie the longitudinal elements with an overlap.

Points 2 and 3 in the instructions can be replaced using a single clamp. It performs the functions of both vertical ligament and transverse reinforcement. Clamps should be no closer than 25 cm to each other. A more accurate step is defined as 3/8 of the height of the foundation.

How to properly reinforce corners, we have already described in the theoretical part. DIY installation instructions are as follows:

- Tie the reinforcement bent at a right angle to the vertical post at the bend point.

- Connect the ends of the rod diverging to adjacent walls with overlapping straight line segments. The overlap size is determined as 40 diameters of the selected rod, that is, for a 12 mm product, it will be at least 48-50 cm.

- Install clamps with a step half as small as when linking two belts on straight sections of the foundation.

Only rods marked with the letter “C” are suitable for welding into a single structure. All others are best connected by knitting, so as not to disturb the structure of the metal at the bonding points.

The metal reinforcement of the foundation has one significant drawback - susceptibility to corrosion. To eliminate the risk of destruction of the reinforcing mesh and weakening of the structure, it is necessary to provide products with reliable insulation from environmental factors.

To do this, even at the stage of laying the rods, it is necessary to ensure that the edges of the reinforcement do not extend beyond the future concrete monolith and do not even come closer to the ground and formwork walls closer than 50 mm. Then, when pouring, all metal rods will be securely hidden under a layer of concrete.