Armature rental is in demand in many areas, therefore, it is produced in an extensive assortment. Each manufacturer must apply a certain marking on the products, which reflects the physical and mechanical properties and performance of products.

What is the fittings for?

Concrete is not in vain is considered one of the most durable and durable building materials. It perfectly withstands the load on compression, but weakly opposed with tensile or shifting loads. Because of this, the design can quickly crack or break.

To improve quality characteristics, reinforced concrete has been used for many years. This is a kind of metal alloy and artificial stone. First, the framework of steel rods is formed in the formwork -. And then concrete is already poured. The resulting structure has all the necessary set of properties: durable, while quite plastic, withstands almost all kinds of deformation loads, including vibration, bending, and the like.

Description of construction reinforcement will be incomplete if we do not list the areas of using steel products. It:

1. Construction of residential minor and multi-storey houses (foundation, monolithic walls, overlaps), industrial buildings, complex special designations (berths, hydroelectric power plants, metropolitan).

2. Erecting various support and protective structures (greenhouses, support for pipelines, columns).

3. Device screed, strengthening plaster.

4. Production of reinforced concrete products of the shaped type (rings, pipes, plates of overlaps, beams, foundation blocks).

5. Formation of roadbed, sidewalks, airfield runways, etc.

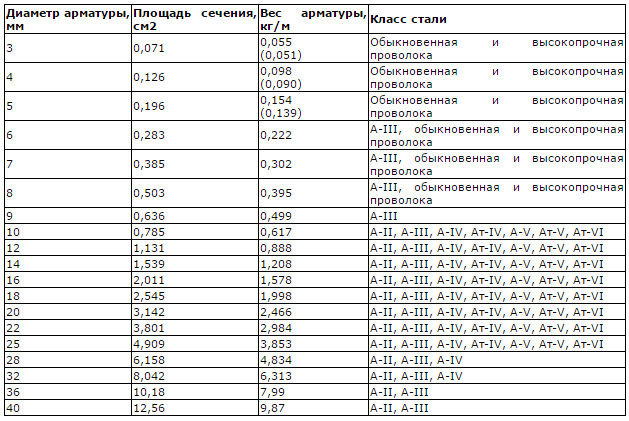

For each of the above region, the armature of a certain variety, type and diameter is manufactured. These parameters are specified as an alphanumeric symbol set on each rod.

Read the label symbols

The character code of reinforcing rental begins with the litera:

- A - hot-rolled or cold rolled (thermoproprotsed) products;

- B is cold-deformed;

- K - ropes.

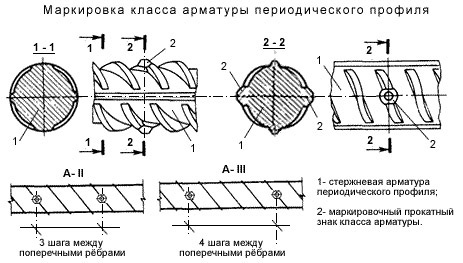

Allocate the following series of reinforcement rental:

1. A240 or A1 - produced from steel brands ST3SP, ST3PS, ST3CP, is classified as mounting rods with a smooth profile with a diameter of 4 to 40 mm.

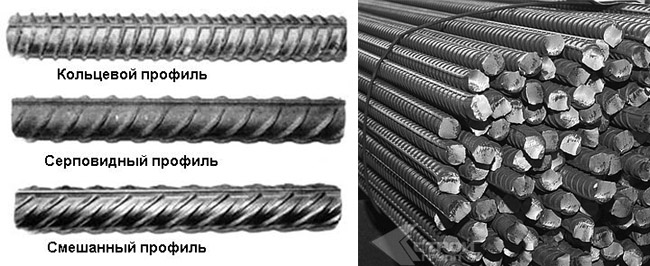

2. A300 or A2 - manufactured from the metal of the ST5SP series (PS) or ST18G2C, refers to the working products with a corrugated surface with a cross section of 10-80 mm. Depending on the diameter, it is made in the form of a wire, rolled by bays or rods 6-12 m long.

3. A400 / A500 or A3- is produced from steel grades 35GS, 25G2C, 32G2R. This is a working reinforcement of a periodic profile by a cross section of 6-40 mm. It also produces in the series "B" from metal by cold pulling. This is the most demanded fittings for the foundation of a slab, ribbon or pile type.

4. A600 or AT4 - produced from low-alloyed thermal-holding (cold-rolled) steel class 80c, 20Hg2c, designed for welded structures. The length of the rods is classified as measured (rods 6, 9 and 11.7 m) or non-meter (rods and bays up to 12 m). The diameter varies from 10 to 32 mm. The surface is periodic, sickle type.

5. A800 or AT5 - is made of metallic low-alloyed raw materials 23x2g2t. Products are produced in diameter of 6-40 mm and is designed to form welded frames in conventional and pre-stressed concrete.

6. A1000 or A6 - from low-alloyed steel classes 22x2g2a, 22x2g2p and 20x2g2c. A distinctive feature is the use of any type of welded work without restrictions. The diameter of the rods varies from 6 to 32 mm.

Marking also includes the indication of special properties of products:

- K - corrosion resistance. The products are subjected to the process of galvanizing, galvanization and others, as a result of which a protective film is formed on the surface, preventing oxidation.

- C - connection by welding.

- T - thermomechanically hardened steel.

After the basic parameters, the diameter is indicated. For example, the marking A500C Ø12 is deciphered as the fittings hot-rolled with a yield index 500 MPa and a periodic profile, designed for welded works, the diameter of the product is 12 mm.

For certain types of products, GOST demands to paint the ends of the rods. The following colors are used for different classes:

1. For reinforcement from low-alloy steel:

- A4 - red;

- A5 - red and green;

- A6 - red and blue.

2. For hire of thermoproprotic metal:

- AT3 - white and blue;

- AT4 - white and yellow;

- AT4K - green;

- AT5 - blue;

- AT5SK - white and green;

- AT5K - yellow and green;

- AT6 - yellow;

- AT6K - green and black.

Color marking complements digital-letter, provides additional information about the product.