I devoted the history of composite materials. I continue to occupy my leisure this topic and today I want to tell a little about the terms and technologies of prototyping using polymer composites. If you have nothing to do with long winter evenings, you can always make a snowboard from carbonistic fabric, a motorcycle case or a case on a smartphone. Of course, the process may eventually become more expensive than buying a finished product, but I wonder something to make your own hands.

Under the cut - overview of the methods of manufacturing products from composite materials. I will be grateful to you if in the comments you will add me to result in a more complete post.

Composite material is created at least of two components with a clear boundary between them. There are layered composite materials - for example, plywood. In all other composites, components can be divided into a matrix, or a binder, and reinforcing elements - fillers. Composites are usually separated by the type of reinforcing filler or by the material of the matrix. You can read more about the use of composites in the post, and this publication is devoted to the methods of manufacturing products from composites.

Manual molding

In the case of the manufacture of products, single specimens the most common method is manual molding. Gelcoout is applied to the prepared matrix - the material for obtaining good finishes on the outer part of the reinforced material, which also makes it possible to choose a color for the product. Then the filler is placed in the matrix - for example, fiberglass - and impregnated with the binder. We remove the air bubbles, we wait until everything cools, and we refine the file - we cut, drill and so on.This method is widely used to create car body parts, motorcycles and mopeds. That is, for tuning in cases where it is not limited to the sticker of the "Under Carbon" film.

Spraying

Spraying does not require cutting glass materials, but instead you need to use special equipment. This method is often used to work with large objects, such as boat housings, vehicles and so on. In the same way as in the case of manual molding, the gelkout is first noted, then the glass.

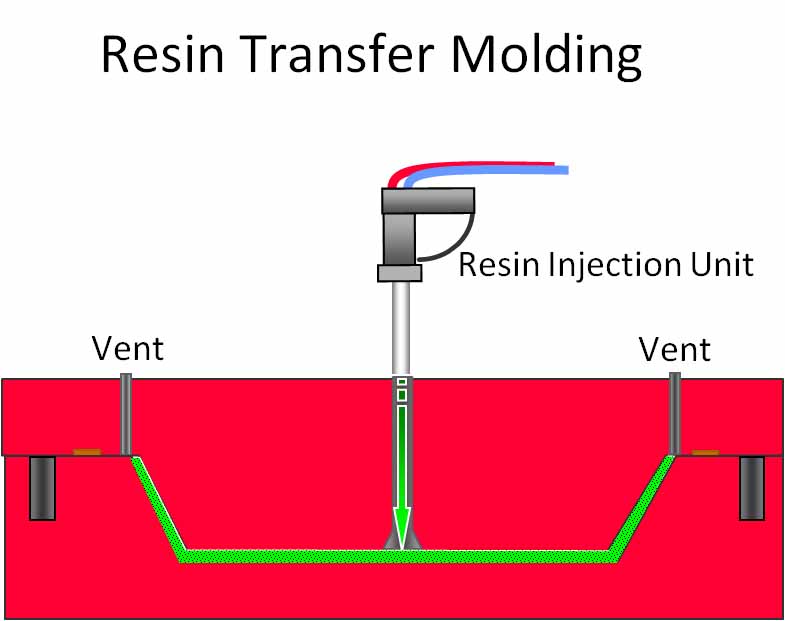

RTM (injection)

When the injection of polyester resin in a closed form, a snap-in from the matrix and a response - PuNson is used. The glass material is stacked between the matrix and the response form, then the hardener is poured into the form under pressure - polyester resin. And, of course, refinement with a file after curing - to taste.

Vacuum infusion

For the method of vacuum infusion, a package is required in which a vacuum is created using a pump. In the packet itself, the reinforcing material is located, the pores of which after pumping air are filled with liquid binding.An example of a method - for the manufacture of a skateboard.

Winding

Method of winding composites allows us to make ultra-light cylinders for compressed gas, for which they use the retra liner, rolled up to 2-5 atmospheres, as well as composite pipes used in the oil producing industry, chemical industry and communal services. It is easy to understand from the name that the fiberglass is wound on a movable or motionless object.On the video - the process of winding fiberglass to the cylinder.

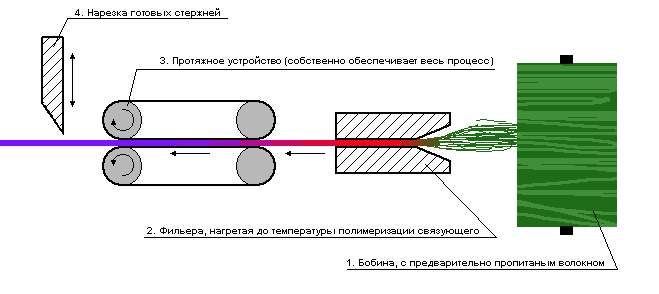

Pultruzia

Pultrausia is a "broach". In this method, the method occurs a continuous process of stretching the composite material through the pulling machine. The speed of the process is up to 6 meters per minute. The fibers are passed through a polymer bath, where they are impregnated with a binder, after which they pass through the preformed device, obtaining the final form. Then, in the mold, the material is heated, and at the output we get the final hardened product.The process of production of tongue piles by Putrusia method.

Direct pressing

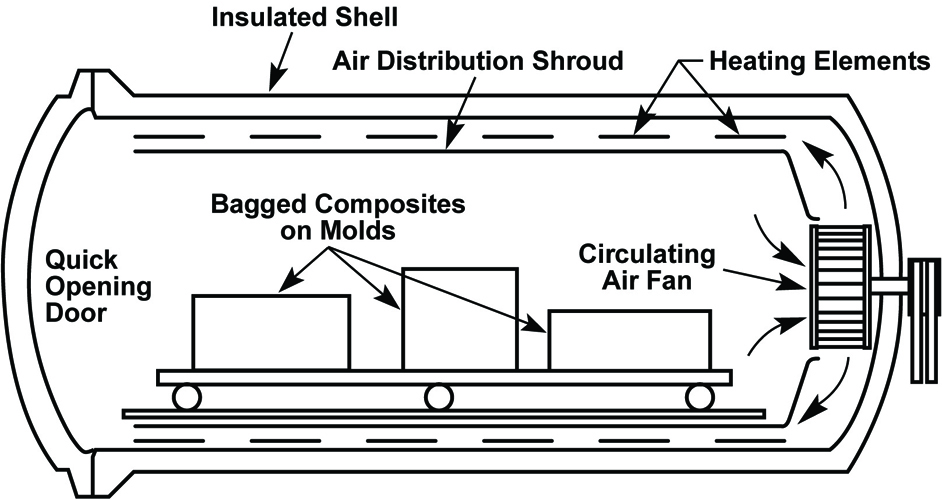

Products from thermoplastics are manufactured in pressure molds. For this purpose, high-temperature hydraulic presses use with an effort from 12 to 100 tons and the maximum temperature of about 650 degrees. In this way, plastic buckets are made.Autoclave molding

The autoclave is necessary for conducting processes when heated and under pressure above atmospheric in order to accelerate the reaction and increase the product output. Composite materials are placed inside the autoclave on special forms.

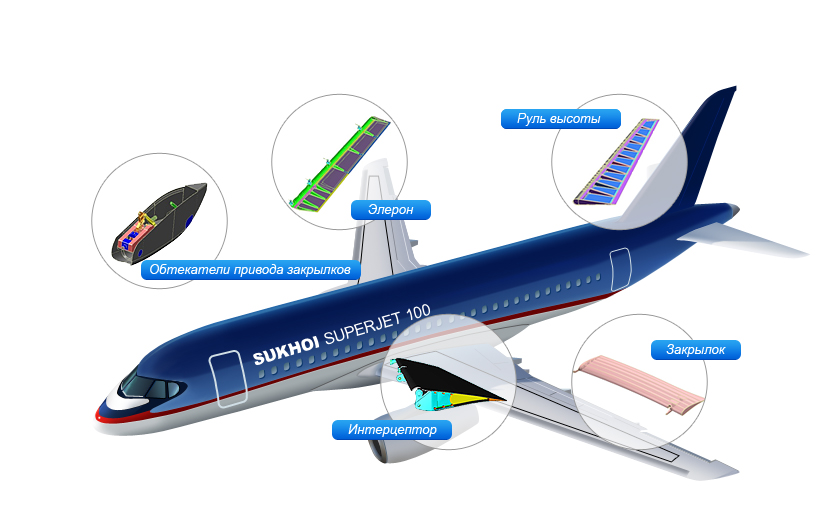

Products from composites

Composite materials are widely used in aircraft. For example, built of them.

Auto industry.

Prostheses and Ortesa.

If you have add-ons, you will definitely write about them in the comments. Thank you.