Hello!

But in this letter I want to express important accents that did not mention the article.

First- These are working seams of concreting. As we present, at a time all the stairs do not conclude. The most likely option: first make the platforms, and then fill marches. But due to the peculiar configuration of the design, it is necessary to thoroughly consider the shape and position of the concreting seams to ensure reliable operation of the reinforced concrete.

Consider the bottom of the march. It is all more or less simple: you can make horizontal seams, and eventually the march will just come around to the platform. Builders also suits such a seam: they are easier to do it than vertical.

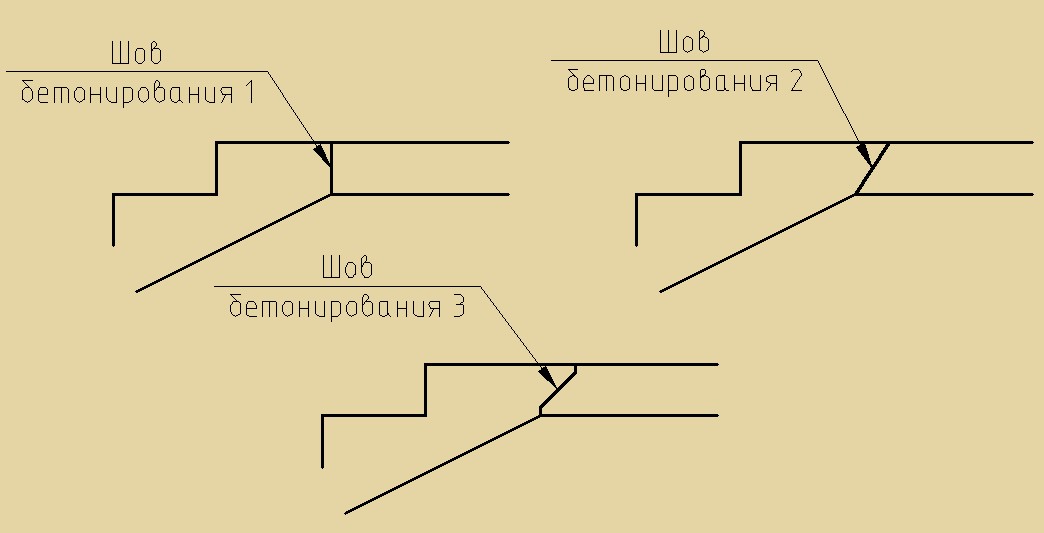

But with the upper part there may be options. Consider three.

In the first case, we seem to comply with the requirement that the seam should be strictly vertical to the concreting surface. But even in appearance, this seam looks suspicious - it seems that under the weight of the inclined march, the whole design will eventually hang on the reinforcement. I would not recommend such a seam.

The second seam is a way out of the first situation. On the one hand, we violate the requirement on verticality, but on the other - the march appears at least some kind of support, and the slippage of the march under its own weight will not be.

The third seam is a solution that is trying to satisfy both conditions: on the one hand, there are vertical sites (within the protective layer of concrete), which will prevent inclined cracks; On the other hand, the inclined seam section does not give march to separate from the site.

In this case, I will not recommend some of these seams, each of the solutions is not perfect. Just think carefully, plug in the design flair and make your choice. Or maybe you will come up with something your best than that. In any case, do not forget that in such difficult situations, the designer is obliged to designate the seams of concreting, without giving them to the bumps to builders - they will not worry, they will do as it is more convenient.

SecondWhat I want to talk about - this is the supporting platforms on the walls of the staircase. If monolithic walls, builders are very inconvenient to withstand the entire technological process described in the article, which I referred to above:

"First, set a formwork for both marches and platforms, while the overlap must be already done, the release of reinforcement from it is provided. After that, we put the lower reinforcement of the marches and the platform according to the drawings, then the upper fittings of the site. Install formwork for steps. Concrete either immediately all, or with technological breaks, but then the working seams of concreting are carried out strictly in the places indicated on the scheme, the concreting is not allowed in the flight of the staircase. Be sure to compact the fresh concrete mixture with vibration. Formwork to disassemble after reaching the concrete at least 70% strength. "

Imagine: for concreting walls it is necessary to make technological breaks at the level of each site. We concreted the wall to the bottom of the same site, made the pad, concreted the walls to Niza the other, again made the platform, they concreted march between them - and again in a circle. Of course, builders start looking for a way out and offer their own options. Which of them can not agree?

The first option is to leave the releases from the walls for sites, to then perform these sites. What is it bad? The fact that the seam of concreting is performed in the most stressful place of the staircase march - in the place of the restructure. It is unacceptable - categorically.

The second option is to leave a niche in the wall, in which the position fittings then will be charged; These niches will be concreted with the playground. What's bad about it? First, such niches are never normally concreted, and concrete does not compact them (I saw such amateur niches live - the spectacle depressing). Secondly, the playground will not rely on the rest of the way, but will hang on small sites. But it is not necessary to forget that the playground keeps on itself the whole march, and this is not a small load.

In general, my advice to you: Carefully consider all the consequences before agreeing to the offers of builders.

ThirdWhat I want to say: if you consider marches of non-standard sizes (distant from typical), be sure to check the inspection. In the center of the march, attach a load of 100 kg, from it the march must bend less than 0.7 mm. Dancing under the legs of marches - not for the faint of heart. And it is harder to correct this slip than to prevent.

I wish you a biggest time to think out the details!

Sincerely, Irina.