Semi-automatic type of welding is one of the varieties of classical electric arc welding. A similar type of welding has a difference in how the electrode falls into the workspace. For this, a special welding wire is applied, which acts as an electrode. It continuously enters the welding head with a constant tempo with a mechanical drive.

To date, it is possible to conduct welding with a semi-automatic with the use of carbon dioxide or without it. This is required in order to completely eliminate the likelihood of air from the welding zone, otherwise, as a result of contact with the environment, the seam will be soft and continuing. It is for this purpose that there are high-pressure cylinders with such gas as: argon, helium, carbon dioxide or their mixtures. However, this type of welding is quite time consuming and costly, and if you just need to make a couple of small seams, we will clearly not buy and refuel the gas cylinder.

In this case, many are wondering, is it possible to weld with semi-automatic gas with ordinary wire?

To create points (tapes), it can and will be consolidated, but for the formation of a high-quality seam is not fully suitable. Sheos succeeded uneven, not to mention the quality. And if you just get acquainted with the semi-automatic welding process, then the welding semi-automatic latter will bring you one disappointment.

So it will still have to fork on the purchase of a gas cylinder and related equipment?

I propose to get acquainted with a possible way out.

Welding semi-automatic powder wire without gas

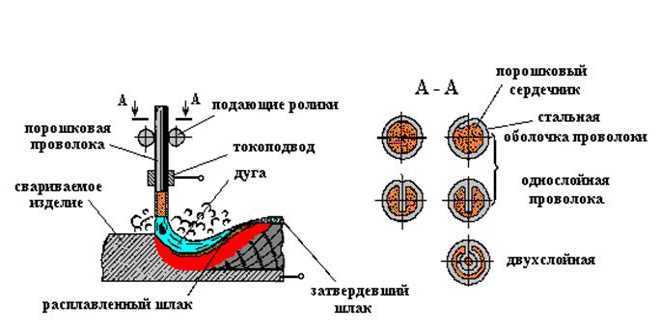

This type of welding without gas is possible due to the use of the so-called powder wire for the machine or, as it is also called the flux wire. From the inside its rod is filled with a special fluxed powder. During the welding work, the flux heats up at high temperature and forms a small gas cloud, the radius of which is sufficient to protect the molten metal.

Powder Welding Scheme

It is worth paying attention to the fact that in the process of cooking vertical seams, heat propagates from the lower parts to the top. In order to avoid such inconvenience, the pistol head should be headed from top to bottom, slightly tilting it to the top, and in the end you will be able to keep part of the heat in the welding bath. Movements should also be carried out in the imminent pace.

Benefits:

- mobility of welding equipment. No need to carry a balloon, gearbox and a bunch of sleeves;

- the presence of the possibility of using a wire is absolutely any chemical composition when forming a seam. We choose what type of metal we will weld.

Disadvantages:

- high cost of welding wire. Here we are talking about really high-quality material, and not a cheap Chinese analogue;

- requires increased attention when choosing the wire itself and the welding machine.

If positive moments for you in priority, it is worth examining the process in the form of a step-by-step instruction

The process of semi-automatic welding with your own hands

Here you can find out how to cook semiautomatics yourself. The algorithm algorithm itself requires experience and enhanced control. Otherwise, the welding of the powder wire will be performed poorly. You must properly configure the equipment, for this, a specific sequence of actions is performed:

In conclusion, I would like to note that the semi-automatic flux wedge was possible at home, but it is necessary to weigh everything for and against this method. Any novice welder is not recommended to try to use semi-automatic welding under the flux only because of one single moment - high costs.

You can learn more about this type of semi-automatic welding by looking at this video.