The most popular foundation in private building is a tape. Most often it is a concrete tape on which the walls of the house are relying.

Concrete is capable of making large static loads (as it can withstand a tremendous compression effort), but vulnerable to dynamic loads.

With an effort on stretching, which often occurs when moving and frosty bent of the soil, the ribbon can crack.

So that this does not happen, it is reinforced with a metal rod. How to reinforce the ribbon foundation with your own hands?

What fittings are better for a belt foundation?

Reinforcement of the ribbon foundation can be performed by steel or composite materials, i.e. Metal or fiberglass rods. They are released in bays from 50 to 100 meters, sometimes in the form of a sliced \u200b\u200bmetal rolling from 6 to 12 meters.

Advantages of fiberglass reinforcement for foundation - resistance to corrosion, chemical inertness, non-profitability, lack of electrical conductivity and static electricity. This material is used, for example, when the foundations for technical structures are used for which the absence of radio cells are important.

In private buildings, it is rarely used: due to poor stretching on bending, it does not effectively perform its basic function.

Features and diameter of reinforcement for a ribbon foundation:

- for verticals and across, a smooth or corrugated rod thick is about a centimeter;

- for the longitudinal part of the carcass that takes on the main loads, the corrugated material is selected up to two centimeters (for the private house of this is enough);

- for knitting, steel wire or coupling clamps are used;

- sometimes welding is used to connect the rods. For it, metal with marking "C" is suitable.

For the reinforcement of the foundation is not allowed to use:

- profile corners;

- metal pipes;

- rabita grid, incl. with a large cell;

- iron cables;

- plastic bottles, etc.

How to calculate reinforcement for a tape foundation

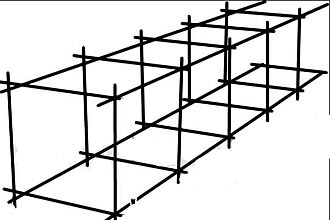

For small-breeding foundations (not deeper than 90 centimeters), the frame is performed from two longitudinal rows, two rods in a row. For swallowed (below ground freezing, i.e. deeper than one and a half meters) Longitudinal bars are put on three or four levels.

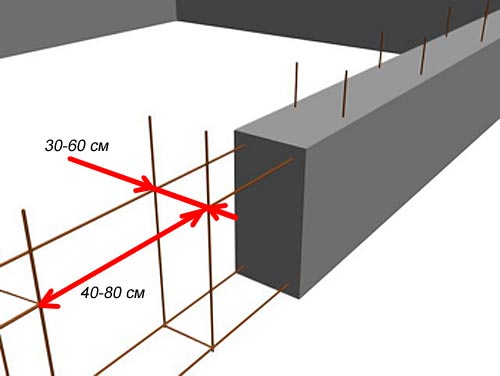

Distances:

- between verticals step from 40 to 80 cm;

- between horizontals - from 30 to 60.

note

In 52-01-2003 SNiP shows the minimum amount of metal: 0.1% of the foundation section. For example, if the height of the tape is 1.2 meters, and the width is 0.4, then the total armature cross section is from 480 square millimeters.

The minimum diameter of the rod depends on the reinforcement conditions:

- longitudinal rod for side up to 3 meters long - 1 centimeter;

- more than three - 1.2;

- accenes with a frame height of up to 80 cm - 0.6 cm;

- more 80 - 0.8 cm.

2. Pour the concrete sole with a layer of 5 centimeters to protect the metal from corrosion. Instead of soles, you can use a more economical option: to put the stones or brick fragments under vertical bars. But it is a long and energy-intensive way.

4. To put on concrete the calculated number of transverse rods in increments within 0.8 cm.

5. Put two rows of longitudinal rods along the walls of the ditches. Tie an intersection. Between themselves, horizontal fragments are combined. The length of the adolescent - 50 diameters of the rod minimum.

6. At the joints to install vertical bars. They are put on a perpendicularly laid lower level, there should be no deviations from the vertical. Tie

7. To verticals to bind the upper tier crossing. The overflow of the ends of the frame at the same time should be at least 20 centimeters.

8. To lay the upper longitudinal rods, copp with the rest of the clamps or wire.

9. Secure the framework relative to the formwork. There should be at least five centimeters between the metal and boards. The same minimum distance is left between the rods and the upper border of the concrete.

For the protection and carcass itself, and concrete from the development of corrosion before starting the installation, clean reinforcement bars from rust and dirt should be cleaned.

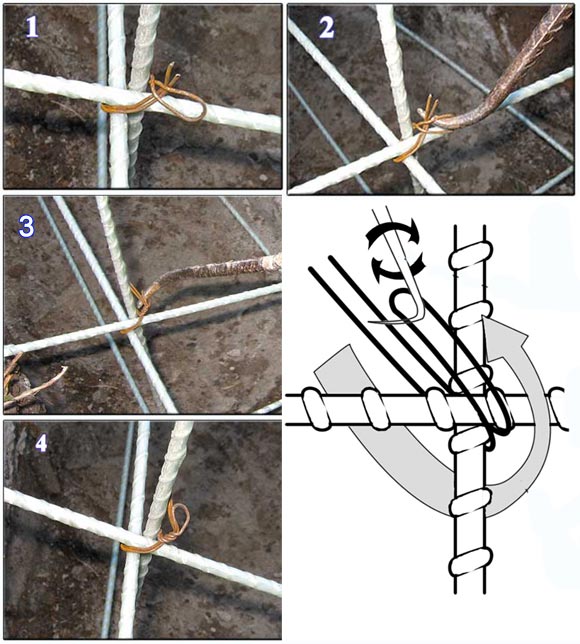

To work, you need a tool: clamps, special hooks for mating wires, canvas or scissors for metal.

A homemade hook can be made from a piece of fittings: to sharpen the ends of the rod 6 or 8 millimeters, bend and put on the opposite end wooden or plastic tube. The handle should be located under a stupid angle to the working part of the hook. On both sides, it is fixed with stubborn washers, the washers stick to welding.

Action when binding:

- Take a bent twice the wire under the desired junction of the rod.

- Pries in crocheted bending bending.

- In two or three turns to tie a loop with another (double) end of the wire.

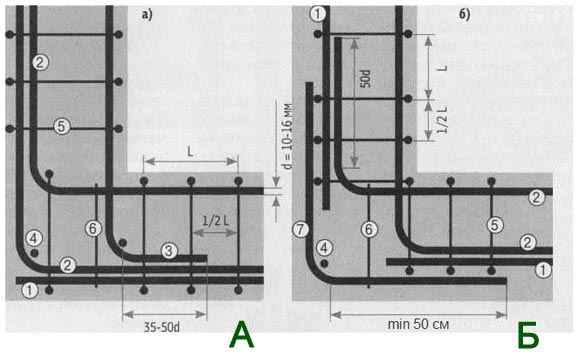

Problem moment during installation - reinforcement of angles. In the corners, concentrated voltage is formed, these are the most loaded points. To compensate for the load, M-shaped or P-shaped gains of clamps are used. M-shaped are used for stupid angles.

A) With the help of adhesion and legs, b) with the help of a M-shaped clamp. 1. Horizontal fittings, 2. Taste, 3. foot, 4. Vertical fittings, 5. Cross fittings, 6. Additional transverse fittings, 7.G-shaped clamp, D - reinforcement rod diameter

The clamps of the desired size and section are installed instead of ordinary vertical rods. In the angular compounds of the clamps should be twice as much as on linear sites.

- Tags: