Hot-rolled fittings on the right can be called an integral component of reinforced concrete structures. But since there are huge loads and stresses on this product, it is only available in accordance with GOST. Our article is devoted to this metal, and it will not only consider the characteristics, but also the features of its operation.

1

This type of fittings is often used in the construction area due to a number of advantages. But before considering the features of the profile, attention should be paid to the term. It will be about the metal rods of the circular cross section, of which the framework of reinforced concrete structures make. Elements of small diameter are produced in the bays.

Hot rolled type of fittings

The reinforcement also call the parts intended for automatic protection, overlapping and controlling the parameters of the working medium in the pipelines of various purposes. In electrical engineering, so-called components and typical parts connecting wires, insulators, etc. Also under the reinforcement they mean headphones with balanced anchor used in audio engineering. In general, the term can be found quite often, but below will be discussed.

Products are made of hot rolled steel. Their main purpose is reinforced concrete reinforced concrete. Thus, it is possible to strengthen the composite material and give it the necessary characteristics. Especially in such hardening, there are places for which the tensile and compression efforts come. In some cases, reinforcement prevents the formation of shrinkage cracks. Moreover, the diameter of the rods and their location is selected involuntarily, and in accordance with strict calculations. However, optionally, this material can be used for other purposes.

2

There are several types of such metal rolling. The classification is carried out not only according to the geometric parameters, form, but also by type of material, despite the fact that all elements consist of steel. Depending on the mechanical properties, this alloy is divided into classes. In our case, the reinforcement is made mainly of hot rolled steel, indicating the symbol "A". The rods belong to the class A-I (240), and the products with a periodic profile: A-II (300), A-III (400), A-IV (600), A-V (800) and A-VI (1000 ). But at the request of the consumer from Steel A300-A800, smooth fittings can be made.

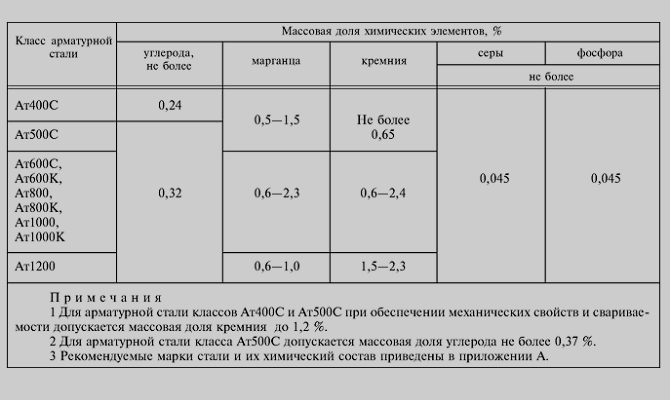

Separate attention deserves thermoproprotic products. In this case, the production is involved in the production steel class AT. The index "C" indicates that the material is characterized by good weldability, and "to" - resistance to corrosion cracking. It is worth noting that the higher the class of steel, the better its strength characteristics, the numbers in brackets correspond to the minimal limit of the alloy fluidity. In reference books, you can easily find tables, where the mechanical properties of the material are indicated - temporary resistance, relative elongation, and even the bend angle in the cold state.

Thermal products

In addition, such fittings are classified as appointment. The profile is divided into working, assembly and constructive. But the most popular should be called the working reinforcement, the main task of which is the perception of stretching effort. But when it is necessary to ensure the integrity of the structure, it is necessary to give preference to a constructive type. Its tasks include stressing shrinkage, as well as temperature stresses and load distribution. With the help of mounting reinforcement, you can create a pretty rigid frame.

It should be noted that the first two species can also perform the role of the mounting elements, but it is impossible to replace the structural or working reinforcement of the profile of another type.

On the form of the surface, the rod elements are smooth and periodic profiles. The latter are characterized by the presence of protrusions, reefs or dents on the surface of the product. Due to this, you can enhance the adhesion of the metal rod with concrete. Most often, the round profile has two rigidity ribs and transverse protrusions located on the same, two or three-way screw line. Looking into technical documentation, you can familiarize yourself with the appearance of the metal in more detail.

3

When we talk about reinforcement steel, we assume carbon and low alloy marks. For example, A-I corresponds to calm, semide and boiling steel ST3, and the class A-V is a structural low-alloy alloy 23x2g2t. You can more accurately familiarize yourself with this information in Guest. Still in the documentation are also tables for which the chemical composition of the alloy can be determined.

Reinforcement steel

Vermatural steel class I-IV is made by hot rolled, A-V - with low-temperature release. Steel A1000 may be subject to either low-temperature leave or thermomechanical processing in the flow of rolling mill. However, provided that after tests carried out within 12 hours, the relative and uniform elongation will not be less than 9 and 2%, respectively, is allowed not to carry out low-temperature leave for steels of the last two classes.

In some cases, the replacement of one element is allowed to other, but all deviations for the chemical composition of alloys must correspond to GOST 380-88. For example, in steel 32G2RPs, it is possible to add zirconium or titanium instead of aluminum, and the amount must correspond to the proportion of the initial element. But the steel 25 G2C, 18G2C and 35GS are sometimes diluted with titanium, but only a mass fraction should not exceed 0.03% in the finished box.

4

The area of \u200b\u200buse of reinforcement largely depends on the chemical composition and properties of steel. In this paragraph, we will consider in detail the features of the use of such building elements. Products consisting of steel A-I and A-II are unrelated. They are used as workers, assembly and structural elements. Of them produce welded grids, as well as frames.

Low carbon and carbon steel steel grades 10GT, EST3PS2 and ESS3P2 are often used for the manufacture of loops of reinforced concrete structures. This is due to the increased value of the relative elongation of the material in the perception of stretching loads. In addition, these brands are characterized by an excellent ability to bend even in cold condition and high performance of shock viscosity. However, there are some restrictions on the alloy of EST3PS2 - if the ambient temperature will exceed 40 ° C, then such steel for the production of loops is not suitable. The advantages of the above alloys include excellent weldability. But ST5 class A-II has some restrictions on the weldability, it is especially rolling with rods with a diameter of more than 32 mm, since the welded joint is more fragile.

Loops of reinforced concrete structures

A-III alloys found their use in the production of conventional reinforced concrete structures. The steel of this type is distinguished by excellent weldability, you can only be called a brand of 35GS. The remaining three classes (A-IV - A-VI) are already related to strain type, their weldability deteriorates somewhat, but it can be called satisfactory.

Play a huge role and parameters of pre-hard structures. If their length is more than 12 m, only steel belonging to the type A-V and A-VI, or a brand of thermally hardened steel, should be used. In the case when there is no such possibility, the A-VIII class reinforcement is possible, but it is subjected to double control when hardening. When exploitation takes place in an aggressive environment, only steel, resistant to corrosion cracking, should be used for reinforcing reinforcement.

We do not always need a whole rod, sometimes we are forced to cut it into parts. It would seem that there should be no questions in this matter. However, there is a small feature. Steel classes A-III A-VI are cutting only in cold condition.

5

Now we will focus on the technological process of production. For the sake of justice, it should be said that it is characterized by consideration, and all the steps are under strict control, because finished products must have high quality. And from the name "hot rolled" it becomes clear that one of the main steps is hot rolling.

Begins the process with steel smelting. The raw material enters the oxygen-converter workshop, if it comes to large production or chipboard. But, regardless of the type of equipment, the workshop must necessarily be equipped with a special installation of the metal adjustment "bucket-oven". With the help of it, you can process and saturate the metal by alloying elements before entering the varietal MNF.

Flap of reinforcement steel

Next, continuously pilts are exposed to high temperatures of 1150-1200 ° C and come to the oscillator. After that, the round roller with a diameter of 55 mm follows the black crates consisting of vertical and horizontal rolls. The output obtains a finished profile with a diameter of 25 mm. If you need to even reduce the diameter of metal rods, they are sent to the piping group of the cell. In conclusion, the product is wounded in the bay either cutting on the dimensional lengths with special volatile scissors.

In order to increase the strength characteristics of the metal and at the same time not harm the plasticity, it is subjected to additional thermomechanical processing. Mostly this operation takes place in the flow of rolling. This uses a discontinuity circuit with self-free. Thanks to such an operation, it is possible to significantly improve the properties of relatively cheap material and avoid expensive processing.

6

At this point, we will pay attention to no less important stages of the production of reinforcement, on which the quality of the finished product is dependent, namely, tests and rules of acceptance. Products are received by parties, and all the elements should be made from the same steel grade, have the same diameter and are issued by one quality document. The battle weight usually does not exceed 70 tons, but in some cases it is possible to increase it to the mass of smelting-bucket. Next, select 2 emails or at least 5% of the elements from the party and are subject to tests.

To determine the geometric parameters of metal profiles, special measuring instruments of the desired accuracy are used. But the surface quality is checked by visual control without the use of any magnifying devices. On the surface of the profile, protrusions and ribs are unacceptable rvanins, tension cracks, sunsets. It is also relected products with the presence of rolling captivity and rolled cracks. Small damage to the ribs, as well as protrusions are possible, but their number should not exceed 3 pieces on the temporon meter. Metal rods are not selected with the presence of minor rust, influx, individual rolled contaminants.

Rabbyness, scalyness and traces of rolled bubbles are also not considered serious defects, the main thing is that their size and quantity are within the normal range. Be sure to measure the curvature of the elements, monitor the mechanical properties and mass of fittings. Also conduct bending tests, shock viscosity and stretching. For this, each rod is cut according to the sample of the required length. But samples for chemical analysis are selected according to GOST 7565-81.

Verification of the quality of reinforcement rods

In mandatory, the diameter of the rod and ovality is measured. Just do measurements not from the very edge, but at least 15 cm at least from the end of the profile. If the fittings are in motki, then minimize 1.5 m and 3 m with weight of less or more than 250 kg, respectively. GOST 12004-81 stipulates all the requirements and conditions that should be configured for tensile tests. Samples are made to check the shock viscosity in accordance with GOST 9454-78 and tests, according to the requirements specified in this technical documentation.

The thermoproprotte steel is subjected to additional tests in a nitrate solution with simultaneous exposure to the temperature of 98-100 ° C and voltage. The result is considered positive if the samples have sustained at least 100 hours in such conditions. In addition, the alloys of the AT400C class alloys, the AT500C and AT600C can be exposed not only to the bending test, but also on the subsequent bend, after which none of the samples should have visible defects (cracks, breaks).

The test product is first deformed until the predetermined angle (90 °) is reached, then heated to 100 ° C, withstand in this temperature for half an hour and cooled. And only after that the element is extension to an angle of 20 °. The axes of the two supports must be perpendicular to the direction of force. And the speed with which tests is conducted cannot exceed 20 degrees / s. Cross ribs must be in the stretch zone. In case of at least one indicator, the results turned out unsatisfactory, conduct repeated tests according to the above-mentioned gestures.

7

Now we switched to the final stage, after the manufacture and quality control, the product is marked, packaged and enters the warehouse. To easily determine the steel class from which the profile is made, the ends of the rods are painted. Red paint is applied to elements from steel A600. If you see a combination of green and red, then we are talking about steel A800. For high-quality alloy A1000, blue and red color is characteristic. The strips with a thickness of at least 20 cm are applied throughout the circumference at a distance of 0.5 m from the edge.

Classes of reinforcement steel

Next, the rods are formed in the battle weight of no more than 15 tons and tied with a rod or wire. At the request of the customer, you can reduce the weight of the battery to 3 tons. Then the label is fixed to each bundle, where the valve class is indicated or the material yield strength. We are talking about thermally hardened elements, it is necessary to indicate the index of weldability and resistance to corrosion cracking.

When entering the warehouse, the products that will be cutted are sorted depending on the desired length of the blanks. It is possible to store metal elements in a closed room or under a canopy, while contacting with an earth flooring should be avoided.

8

This profile imposes very serious functions, so it must fully comply with GOST 5781-82. If the product is exposed to thermomechanical hardification, it is manufactured according to the requirements specified in GOST 10884-94. Any inconsistencies can lead to very serious and even deplorable consequences, up to the catastrophe. The technical documentation contains tables where the parameters of each specific type of fittings are specified. Mostly the product number corresponds to its diameter.

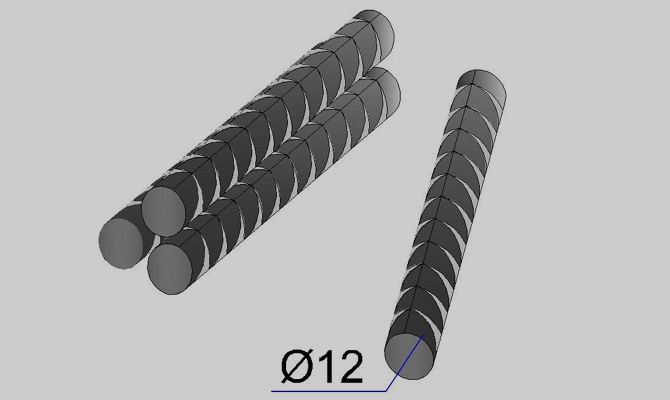

For example, if we are talking about profile 12, then the diameter of the rod in this case is 12 mm. Also, the tables indicate the cross-sectional area, the theoretical mass of the 1 M of the rod element and its limit deviations. The mass of the rose meter is determined by the calculation. In this case, the dimensions of the element and the density of the material are taken into account. But to get acquainted with the limit deviations in diameter, should be viewed in GOST 2590-88. All sizes and their limit deviations are stipulated in the technical documentation, only the relative shifts of screw protrusions are not normalized.

Hot rolled profiles diameter 12

If we are talking about the core elements, the length of one product is in the range from 6 to 12 m. The curvature cannot exceed 0.6% of the length. For steels of class A300 and A400, a decrease in the maximum permissible time resistance to a value of 426 MPa and 560 MPa, respectively, is allowed. At the same time, the relative elongation should be more than 30% and more than 20% for A300 and A400.

Ovality is the difference in the maximum and minimum diameter of one profile, and quite serious requirements are presented to it. This parameter should not exceed the amount of limit deviations in diameter. From steels of class A240 and A300, elements with a diameter of up to 12 mm are manufactured, with a diameter of no more than 10 mm, steel A400 is used, and the remaining 3 classes are perfectly suitable for the production of elements with a diameter of 6 and 8 mm. And the latter most often supplied in motges.

But the thermally hardened elements of the periodic profile need to withstand the angle of inclination of transverse protrusions. This value must be from 30 to 45 °. The angle between the longitudinal axis and transverse protrusions is 45 °, but in some cases it is allowed to increase to 70 °. The rod elements are made of a dimensional length of 5.3-13.5 m, but at the request of the client is allowed production of rods long and 26 m.