Smooth fittings are more versatile material, if you compare it with similar products with a corrugated profile. But despite the versatility of such reinforcement, it is not recommended to be used in cases if it is necessary to create reinforced concrete structures that differ in high strength. To date, several types of smooth fittings are produced, differing as manufacturing technology and its strength.

Applying fittings for smooth profile

Steel fittings are the main element used for an effective reinforcement of concrete structures. With the help of such metal rods, the strength of parts of building structures (overlaps, foundations, columns), single parts (beams, plates, staircase elements), as well as a variety of products made from concrete (pillars, pipes, slabs of overlapping, etc.) are reinforced.

Steel fittings with a corrugated profile have the best adhesion properties with concrete, therefore it is used to create structures to which increased requirements for their strength, reliability and durability are presented. Meanwhile, the cost of corrugated reinforcement is higher than the price of products with a smooth profile, so the use of the latter in many situations when they are able to provide the required characteristics of concrete structures, is more economically appropriate.

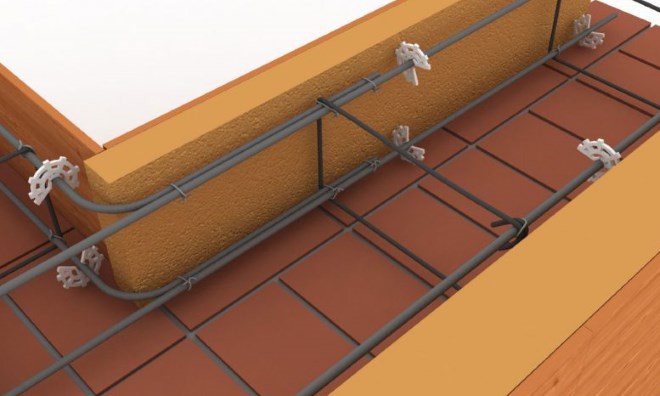

It is practically not to do without smooth fittings if concrete products of decorative purposes are created and weakly loaded during operation. Such products, in particular, include: short pillars and oversized columns, thresholds, floor screed and walls, building blocks, paving slabs, etc. With the help of smooth steel reinforcement, masonry seams between bricks and construction blocks are also reinforced than significantly increase their strength. And, accordingly, improve the strength characteristics and stability of the walls of the built structure. With such reinforcement, smooth steel rods can be laid into dissolve seams as separate elements or be linked to the reinforcing grid.

The universality of smooth steel reinforcement is also that such an element is used not only to improve the strength characteristics of various products from concrete, but also to solve a number of other tasks. The most common areas of application of this reinforcement are:

- production of hardware products for construction purposes and for use in other fields of activity: bolts, nuts, studs, etc.;

- use as elements of metal structures of various purposes;

- production of loops for lifting and installing concrete and metal structures;

- the creation of fences and other enclosing metal structures;

- use as elements of the grounding circuit.

Clamps made from the welded letter "g" smooth fittings

Requirements for smooth steel reinforcement

The standard contains the requirements for the technical and other characteristics of the most common types of fittings of the smooth type, is GOST 5781-82. The provisions of this GOST negotiate requirements for hot-rolled steel products having a round cross section and a periodic or smooth profile. The appointment of such steel products, as indicated in GOST, is the reinforcement of ordinary, as well as in advance of intense structures produced from concrete.

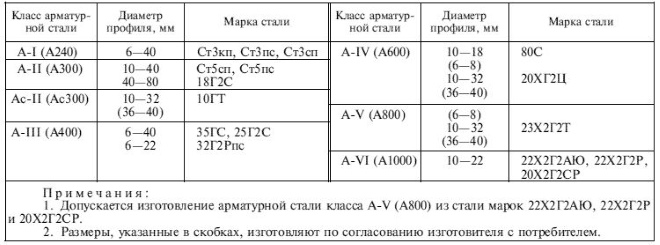

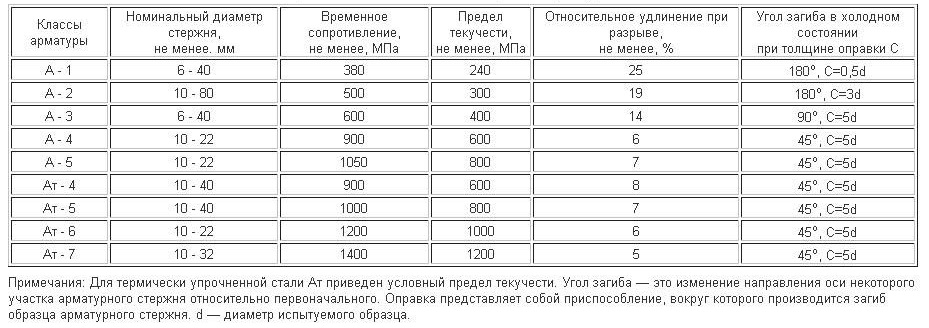

The State Standard 5781-82 divides reinforcement steel to a number of types, depending on the strength, mechanical, as well as other properties of this material:

- A-I (A240);

- A-II (A300);

- A-III (A400);

- A-IV (A600);

- A-V (A800);

- A-VI (A1000).

According to the design class of a material that is visible in brackets, you can find out its characteristic as the yield strength. In general, next to the letter designation is not the result of steel yielding limit for the production of a certain class fittings, measured in kgf / mm2, and its value, increased 10 times. So, for steel class A1 (A240) the yield strength is 24 kgf / mm2, and for the material of class A2 (A300) - 30 kgf / mm2.

According to GOST 5781-82, only fittings of class A1 are produced with a smooth profile, and products of all other categories - with periodic. Meanwhile, GOST also stipulates the possibility of production with a smooth profile of steel reinforcement Classes A2-A5, if this wishes the customer.

Among the consumers of reinforcement products, fittings belonging to the class of class I are the most popular. It is released only with a smooth type profile. It is for this reason that the provisions of GOST are provided for the production of reinforcement of all other classes mainly with a periodic profile.

The high popularity of class A1 reinforcement is due to the fact that only mechanical properties, as well as other characteristics of the material used for its manufacture, make it possible to take advantage of all the advantages provided by a smooth profile. Carbon steel grades of ST3SP, ST3PS and ST3CP, from which class A-I is manufactured, makes such a product of truly universal. This steel fittings are not bad, it is perfectly welded and easily succumbed to other methods of processing.

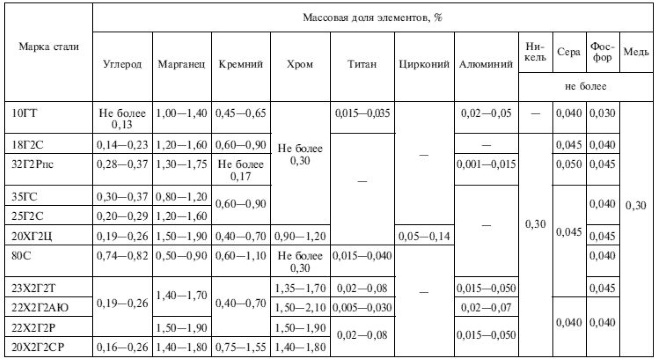

In accordance with GOST 5781-82, the reinforcement products of other classes are made of carbon steel with higher strength characteristics or from low-alloy steel alloys. So, materials to obtain valves of various types are:

- A-II - ST5SP, ST5PS, 10GT, 1NG2C;

- A-III - 25G2C, 35GS, 32G2RPs;

- A-IV - 20Hg2c, 80c;

- A-V - 23X2G2T, 22X2G2R, 22X2G2AY, 20X2G2SR.

If the chemical composition of low-alloyed steels used for the production of reinforcement products are negotiated by the provisions of GOST 5781-82, then for carbon steels there are norms of another standard: 380.

A variety of reinforcement products smooth type

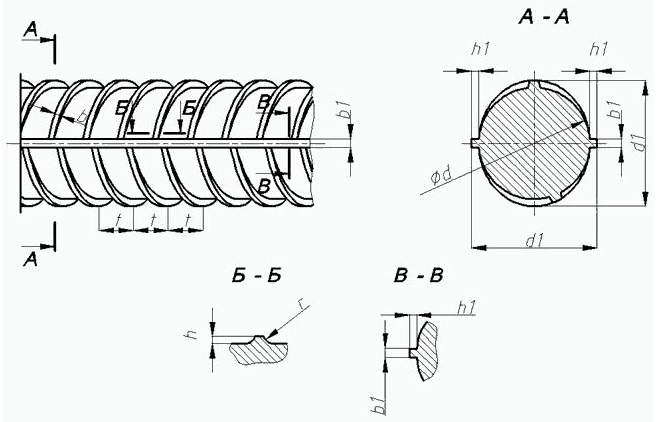

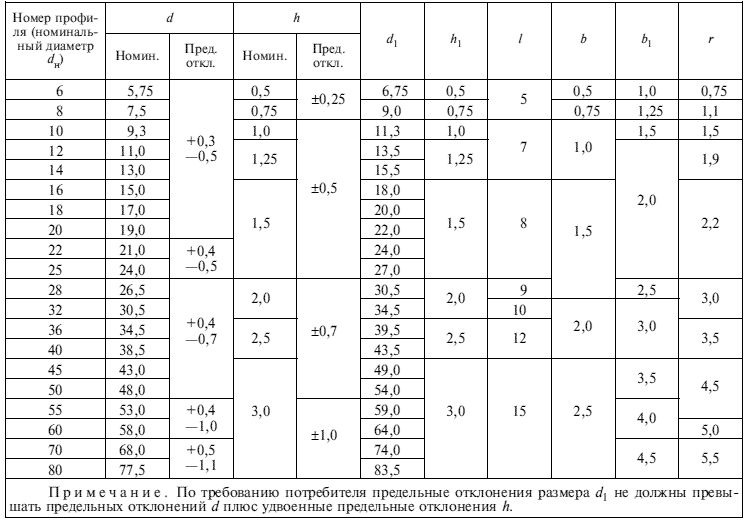

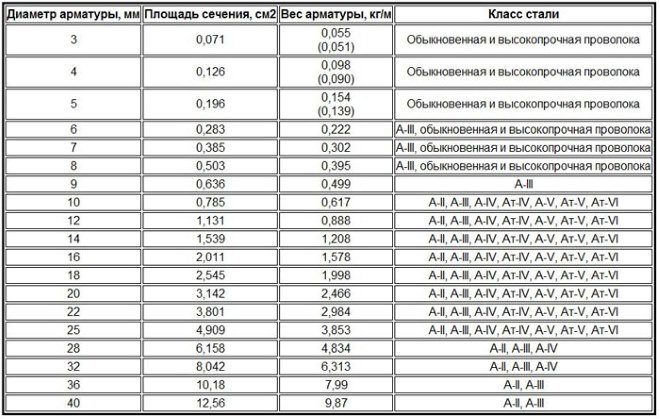

GOST 5781-81 stipulates not only the technical and remaining characteristics of the reinforcement products of the smooth profile, but also their sorting, which includes 20 sizes of such reinforcement. Thus, the provisions of GOST envisages the release of smooth reinforcement of the following diameters: 6, 8, 10, 12, 14, 16 mm, as well as 18, 20, 22, 25, 28, 32, 36, 40, 45, 50, 55, 40, 45, 50, 55, 60, 45, 50, 55, 60, 45, 50, 55, 60 70 and 80 mm. The area of \u200b\u200bthe reinforcement of each size and its specific mass (theoretical) can also be found from the provisions of GOST 5781-82. For example, theoretical weight of the reinforcement, the dimer of which is 16 mm, is 1.58 kg, and the products with a diameter of 80 mm are 39.46 kg.

The standard also stipulates the rules for the designation of reinforcement products, as examples of which can be considered the labeling of the following elements:

16-A-I (A240) GOST 5781-82 - the reinforcement bar with a diameter of 16 mm, corresponding to the class A-I;

22-A-IV (A600) GOST 5781-82 - a class A-IV reinforcement rod, the diameter of which is 22 mm.

In the table, which presents the entire range of smooth reinforcement, you can find out all the sizes corresponding to each class of products, as well as their specifications.

Deviations that may have in its nominal diameter are negotiated by the provisions of the standard 2590. Its requirements are obliged to correspond to all hot-rolled rolling of round-section, the diameter of which is in the range of 5-270 mm. It is stipulated by the standard and such a parameter of round reinforcement rods, as their ovality, calculated as follows: The difference between the largest and smallest values \u200b\u200bof the actual diameters of the profile measured in one section takes. This difference, according to the requirements of GOST, should not be larger than the amount of tolerances (positive and minus), specified for this diameter.

Reinforcement steel related to different classes, as well as various diameters, manufacturers are released in the following form:

- the armature relating to the A-I and A-II classes, with a transverse size of up to 12 mm, is allowed to supply to customers in rods or sweating, and if its diameter is more - only in the rods;

- products related to the class A-III with a cross-sectional size of up to 10 mm are allowed to supply in motges or in the form of rods, if the diameter is greater - in the rods;

- the armature of the A-IV and A-V classes is supplied mainly in the rods, with the exception of products with a transverse size of 6 and 8 mm, by prior arrangement with the customer such products can be supplied as motels.

The length of the rods of reinforcement, which can be in the range of 6-12 m, is also required to comply with certain requirements. Thus, the rods can be released to the customer of dimensional and non-night length, a lot of dimensional length is also allowed, which contains no more than 15% neuroral rods, the length of which is at least 2 meters. The regulatory document is allowed that by prior arrangement with the customer of the rod, smooth reinforcement can be cut down the length in the range of 5-25 m.

For the length of measuring products, which can correspond to normal or high accuracy, the following are negotiated by the following tolerances:

- reinforcement rods, the length of which does not exceed 6 m: the usual accuracy - +50 mm, cutting increased accuracy - +25 mm;

- products longer than 6 meters: normal accuracy - +70 mm, elevated - +35 mm.

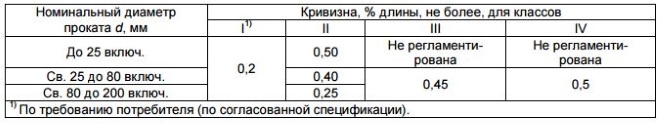

Standards the standard and curvativity of steel reinforcement rods, this parameter should not be greater than 0.6% of their length. Smooth reinforcement rods of steel A-I-A-IV are not subjected to further heat treatment, and for Class A-V products, manufacturers perform a low-temperature vacation. Such thermal processing in accordance with GOST can not be performed if after the tests that need to be carried out for 12 hours after the production of products, the value of the relative elongation of the reinforcement is at least 9%, and a uniform - minimum of 2%.

Mechanical properties of fittings

GOST on, as already happened above, stipulates various specifications and mechanical properties of products. With all of these characteristics and properties, you can read by studying the appropriate tables, but for information we consider some of them.

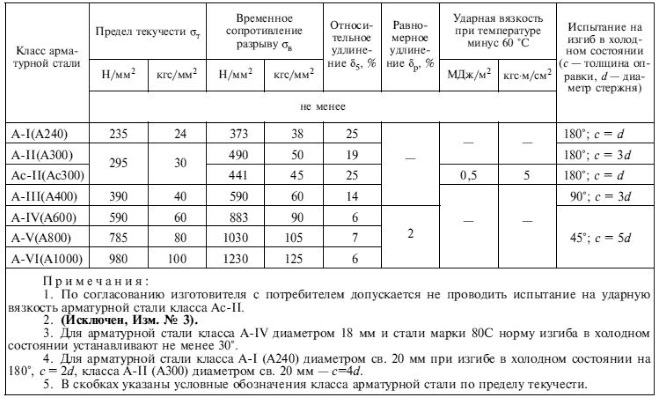

To such parameters of smooth reinforcement, as a temporary break resistance, minimal relative and uniform elongation, the standard stipulates the following requirements:

- A-I: 373 N / mm2 (38 kgf / mm2); 25%; The indicator is not rationed;

- A-II: 490 H / mm2 (50 kgf / mm2); nineteen%; non-normalized indicator;

- A-III: 590 N / mm2 (60 kgf / mm2); fourteen%; non-normalized indicator;

- A-IV: 883 H / mm2 (90 kgf / mm2); 6%; 2%;

- A-V: 1030 H / mm2 (105 kgf / mm2); 7%; 2%.

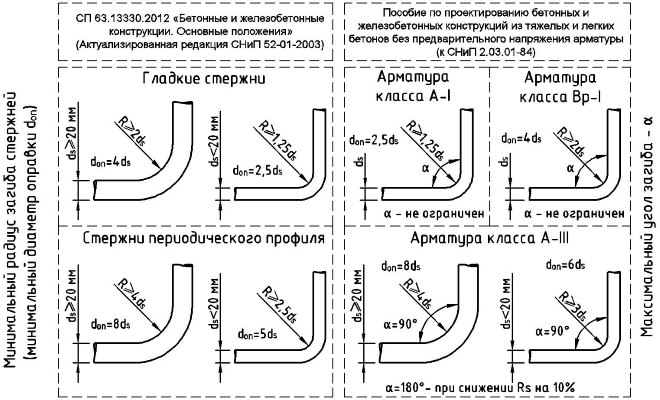

The steel reinforcement of a smooth type is subjected to bending tests, and for each class, mandrels are used with various parameters:

- A-I: the diameter of the mandrel - C is equal to the diameter of the test fittings - D, the bending of the product is performed at an angle of 1800;

- A-II: C \u003d 3D; The bending of the reinforcement is also performed on 1800;

- A-III: C \u003d 3D; The bending is performed by 900;

- A-IV: C \u003d 5D; Bending is performed by 450;

- A-V: C \u003d 5D; Bending is also performed by 450.

Bending test parameters for reinforcements of different diameters are also vary. So, for class A-I products (transverse size exceeds 20 mm), the bending is performed on the mandrel, the diameter of which is 2D; For elements of class A-II (diameter also exceeds 20 mm), a mandrel with a diameter of 4d is used. The indicators obtained during such tests should be at least 0.95 from the values \u200b\u200bspecified in GOST 5781-82.

Conducts GOST and the condition of the surface of reinforcement rods, which should not contain rolling cracks and damage resulting from voltage, so-called rolling captivity, Rvannin and sunsets. Separate prints, rolling sticks, pollution, small areas of corrosion, scalyness and ripples on the surface of the rods can still be present. The quality and simplicity of weldability of reinforcement rods will be completely dependent on the chemical composition of steel, as well as on the technology of their manufacture.

Other regulatory documents

Steel reinforcement products with a smooth profile, which additionally undergo hardening by the thermomechanical method, are manufactured according to GOST 10884-94. The requirements of this regulatory document are applied to products with a transverse size of 6-40 mm, used for reinforcing concrete structures.

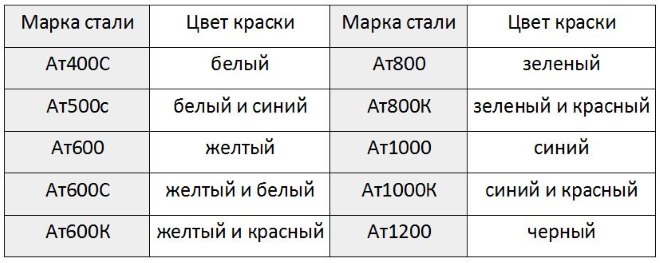

Strengular reinforcement from steel is also represented by several classes to which it is subdivided, depending on the parameters below.

- Mechanical properties of reinforcement. Under this parameter, the class of strength, which is determined by the conditional or actual (physical) yield strength measured in H / mm2 is implied.

- Operational characteristics. For this parameter, the reinforcement refers to a weldable (C) and characterized by increased resistance to such a factor as corrosion cracking (K).

So, depending on the above parameters, the strengthened fittings of the smooth type are represented by the following classes: AT400C, AT500C, AT600, AT600C, AT600K, AT800, AT800K, AT1000, AT1000K, AT1000.

According to the standard 10884-94, products with a periodic profile are predominantly produced. An exception can only be AT800 class products and with a higher level of strength, which, according to the manufacturer and customer, can be manufactured with a smooth profile. If the strengthened fittings are produced with a smooth profile, then its important technical parameters: weight, cross-sectional area, tolerances for mass deviations and geometric parameters, curvature, ovality of products, etc. should be laid in the framework of the requirements of GOST 5781-82.

The following products of the produced products are applied to various classes of smooth hardened fittings:

- AT800 - 10-32 mm;

- AT800K - 18-32 mm;

- AT1000, AT1000K - 10-32 mm;

- AT1200 - 10-32 mm.

The length of the rods of smooth hardened reinforcement, which is negotiated at the placement stage, may be a dimensional (5.5-13.5 m) and permissible measuring (length up to 26 m). Permissible deviations of the length of the rods of such valves should also comply with the requirements of the standard 5781-82.

The rules for marking a smooth fittings relating to the hardened type are no different from the order of the designation of elements that relate to the usual category.

Specifications for harmonious fittings

Reinforced-type reinforcement products are made exclusively from low-alloyed steels:

- AT800: 08G2C, 10GS2, 20GS, 20GS2, etc.;

- AT800K: 25С2R, 35GS;

- AT1000: 20GS, 20GS2, 25С2R;

- AT1000K: 20HGS2;

- AT1200: 30xc2.

The strengthened fittings of the smooth type according to the parameters as temporary resistance to the gap (H / mm2), the yield strength (H / mm2), the relative and uniform elongation (%) must comply with the following values:

- AT800: 1000; 800; eight; 2;

- AT1000: 1250; 1000; 7; 2;

- AT1200: 1450; 1200; 6; 2.

The smooth reinforcement of these types is also checked for bending, for which the mandrel is used, the diameter of which is 5D, and the product itself is bent at an angle 450.

A very important requirement for hardened fittings made with a smooth profile is that such products should not be destroyed even after 2 million cycles of the voltage applied to them, the value of which should be at least 70% of the values \u200b\u200bof the limiting tensile strength (nominal) What corresponds to the material of the manufacture of the rod.(Votes: 2 , average rating: 5,00 out of 5)