For a beginner entrepreneur, the production of fiberglass fittings is one of the promising options for opening your business. Since it does not require huge capital investments and labor costs.

- How much money is needed for the start of the business for the production of composite reinforcement

- How to start a business for the production of fiberglass fittings

- How much can you make money on the production of fiberglass fittings

- What equipment to choose for the production of fiberglass fittings

- How much money is needed for the production of composite reinforcement

- Which OKVED must specify for business

- What documents are needed to launch a business project

- What taxation system to choose for the production of composite reinforcement

- Do I need permission to work

- Composite reinforcement production technology

Of course, today in the construction of materials, the mass of materials is used, on the release of which you can work well.

If we establish a business at the production of composite fittings for proper quality, with an appropriate organization of output and worked by the clientele, then you can return the primary costs in fairly short time and getting a clean revenue in the next 2-3 years after opening.

In essence, fiberglass or composite fittings are a bundle of solid glass fibers characterized by high strength. The deformity threads through a synthetic resin are connected to a durable rod.

Such products, as a rule, are used in the area of \u200b\u200bconstruction and finishing or in everyday life (for example, for the assembly of greenhouses). In addition, unlike metal reinforcement, fiberglass products are not welded, but is bonded by special fasteners (clamps).

Also, fiberglass (composite) fittings are known as "non-metallic".

Equipment for the production of composite reinforcement

How much money is needed for the start of the business for the production of composite reinforcement

The amount for starting attachments (opening business for the production of composite reinforcement) is approximately 1,400,000-1,700,000 rubles.

How to start a business for the production of fiberglass fittings

Evaluating business for the production of fittings from fiberglass, we can say the following:

- The richness of the market is still in the averaged stage and still has free niches to fill with newcomers by entrepreneurs.

- The complexity of the opening of a 10-point scale is equal to 6 points.

Of course, for promising development of the business, you must first of all acquire qualitative and warranty equipment. Having bought it, simulating and launching the production of products can be put on the market in demand for fiberglass (composite) fittings, both small private builders and major construction companies.

At the same time, even with a minor investment investment, the design of documents and the choice of the place of development of the workshop, for the successful development of cases on this field, it is necessary to carefully work out a business plan for the production of fiberglass fittings, in which the following items must be taken into account:

- analytical forecast of market development and competitive base in this area;

- product production technology;

- technical equipment of the premises of the workshop;

- financial rationale for the production of products from fiberglass fittings.

How much can you make money on the production of fiberglass fittings

For example, with an average productivity of 150 thousand s. The finished monthly product, its value in the large-scale market will be about 6-10 rubles for the temporon meter, with a revenue of 1.5 million rubles. At the same time, to reach the figure of net profit, it will be necessary to calculate the variable costs of the acquisition of raw materials, pay for taxes and wages to employees, as well as expenses for communication, transportation and utility deductions.

Of the practice it becomes obvious that the monthly net revenue of the enterprise will be about 100,000 rubles, that is, with such a well-fulfilling situation, the return on business will be 2-2.5 years.

All these indicators, with full production, must be calculated in the business plan. Since in this case it will be visible, whether production is cost-effective or not.

What equipment to choose for the production of fiberglass fittings

Since the production of fiberglass reinforcement uses special equipment to contain and operate under certain conditions, when opening a business, it is necessary to understand and know that it includes and which parameters of the premises content of the premises will be taken into account in the production of construction fiberglass material.

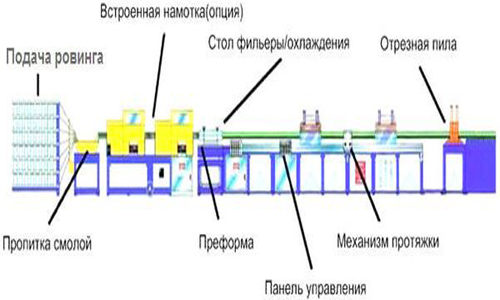

So, the equipment for the production of composite reinforcement includes the following list of nodal items:

- a tumbler, which is a machine for unwinding Roving (fiberglass filament or basaltolocular);

- impregnating device for impregnating the binding material of the threads;

- impregnating bath, in which there will be a special mixture based on epoxy resin;

- rib winding, device for forming a profile and twisting thread;

- thermal polymerization chamber;

- fixtures for cooling reinforcement;

- pulling fixture;

- fixture for winding reinforcement on the drum or cutting device;

- computerized line management system.

Such a line of technological production can be adjusted to one or two streams. At the same time, when delivery of the ordered equipment, it is recommended to purchase a set of technological and technical documentation, and the installation and commissioning of work with the launch of the trial batch, a selection of recipes and technological parameters for the production of composite reinforcement, taking into account the individual conditions for the production of products, the training personnel to include in the order price.

The conditions for the premises in the production of fiberglass fittings are as follows:

- The air temperature should be from +16 to + 20ºС.

- The room should be height from 250cm and above, with a minimum length and width - 25x4m.

- The production workshop must necessarily be equipped with an exhaust ventilation system and fire extinguishing, with access and water consumption of at least 0.5 m 3 / h.

When complying with all indicators, as well as the data specified in the business plan to implement composite reinforcement, designed for high profitability, under the conditions of one hundred percent sales of goods and the content of packets of documents in a proper order, open the production of fittings is quite real and profitable. Good luck!

How much money is needed for the production of composite reinforcement

The main costs of activity are:

- Rent of the workshop and its equipment in accordance with the norms - 100 thousand rubles;

- Purchase of a special production line - 1 million rubles;

- Acquisition of an additional tool - 200 thousand rubles;

- Purchase of raw materials - 400 thousand rubles;

- Registration and other expenses of economic activity - 100 thousand rubles.

Which OKVED must specify for business

When registering fittings from fiberglass, the OKVED code 23.14 is indicated.

What documents are needed to launch a business project

The optimal choice of legal form is the registration of a legal entity, namely LLC. It is worth providing an appropriate package of documents, which includes the company's charter and solving all founders to organize a production shop. Business is designed to cooperate with large construction companies that are more willing to cooperate with the legal entity than with IP.

What taxation system to choose for the production of composite reinforcement

Both for ITP and LLC is rational to use USN. The tax rate is selected individually: 6% or 15%. Accounting and the decision of legal issues should be entrusted to the company for the provision of accounting and legal services.

Do I need permission to work

Licensing Organization of the production workshop is not subject to. But it is necessary to obtain permission from fire inspection and other controls. The document is issued for compliance with the standards. Certificates should also be issued.

Composite reinforcement production technology

Composite reinforcement is a popular building material. But you should not count on superflores in the first months of work. Permanent customers appear with time. If we talk about the production process, then it is worth noting that it consists of several stages:

- Impregnation of filaments of fiberglass polymer resin;

- Giving raw materials rod;

- Polymerization;

- Winding and fastening profile.

The product from fiberglass is made on special equipment automatic method. With the help of a computer, management is managed by the entire manufacturing process.