If the construction project provides for the construction of several floors, then in any case it will have to decide the issue of an inter-storey message. The use of ready-made bribes in private architecture is not justified, because they are limited to the framework of standards. Therefore, many private developers prefer structures performed on their own technology.

Optimally organize an inter-storey message so that it is comfortable for everyone, competent calculations will help. Of course, the parameters can be determined by an experimental way, making measurements of the real object that is convenient for you. However, the best choice will be the proven methodology for calculations.

At the design stage, it is impossible to forget that reinforcement of the staircase monolithic and design drawings are indispensable to ensure the reliability of the finished product. In this case, the settlement process should consider:

- Compliance of the width and height of steps.

- Equipment of mortgage elements.

- Safe approach to the object.

- Convenient descent and lifting.

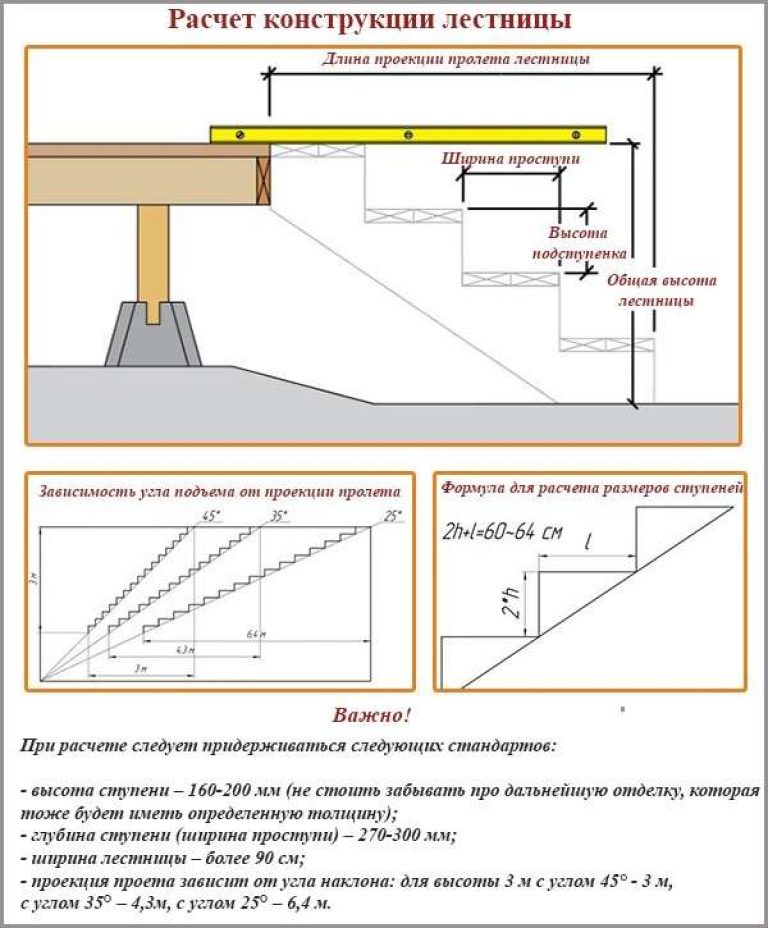

The plane of the stage, located horizontally, architects are referred to, and vertically - the riser. The width of the sticking should provide a support for the feet of at least 80% of its length. Comfortable are the steps with an expaying 300 mm wide, smaller values \u200b\u200bwill make the descent and the rise are inconvenient. The design of staircases is made taking into account the following points:

- For free passage, the width of the span is made at least 800 mm, and if the overall objects are expected - 1200 mm.

- The height of the riser depends on the width of the sticky. For example, for steps of a 300 mm width, a height of 150 mm will be optimal. When the monolithic staircase and the drawing is planned to do with steps on 10 mm wider, then it is necessary to reduce the risers and vice versa.

- Traditionally, the calculations takes into account that the sum of the sticking width and the double height of the riser corresponds to the human step in 400-600 mm. However, these figures are individual and depend on human growth. If there are children in the house, the tread is usually increased, and the width of each stage is reduced.

- Learn the number of steps is easy - the distance between the floors is divided into the height of the riser. Fractional residue from the result of division will be the height of the first frieze step.

- Alternating the number of steps to the width of the sticky, we obtain the length of the horizontal projection of the march. This will allow you to find whether the span will fit into a given space.

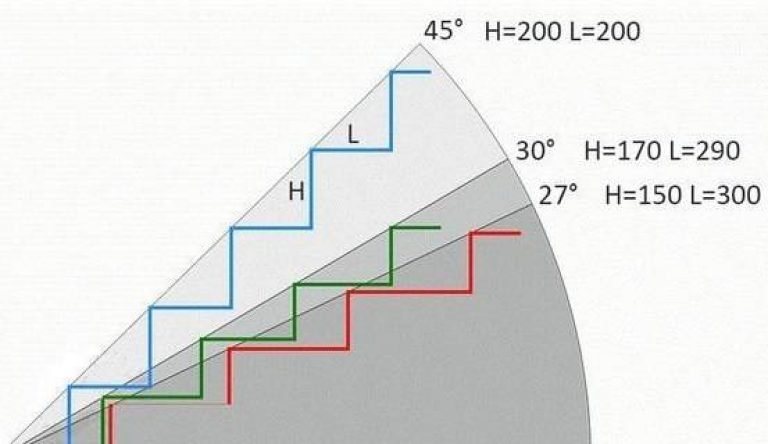

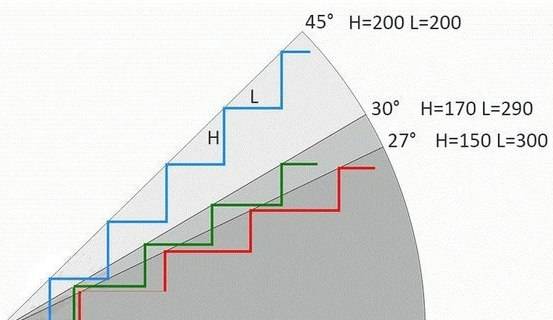

- In the case when the stair march does not fit, it is in short, increasing the angle of lifting. It is optimal to take an angle of 25-37 degrees, the coolest rise causes difficulties during the descent. Determine the angle allows the diagram of a rectangular triangle, where the costs are oppressed and coming. Dividing the height on the width of the step, and applying the tangent table of the angle, we obtain the angle of the shuttlefish.

The development of drawings and reinforcement of the monolithic concrete ladder implies the organization of fences and mortgage elements. On average, the weight of such a design is in the range of 2-2.5 tons, so it is important to consider the base device. Proven practice option -

and reinforced concrete beams.

Do not move away from the optimal size of the height and width of the steps, if you do not want to sacrifice comfort. It is better to organize a platform, dividing the span. Calculate 5-6 overall steps at the bottom of the span or make it spiral.

The screed on the soil is calculated so that the weight of the monolith does not give pressure exceeding 1 kg / cm². The weight of the finishing material is taken into account if the load exceeds the permissible norms, it makes sense to finish with lumber.

Principles of reinforcement of monolithic ladders from concrete and design drawings

Constructive staircase is a self-sustaining design. An additional support is necessary only in the case when the rotation of the march is more than 180 degrees. In other cases, it is necessary to compensate for loads in the form of columns or fastening to the walls.

Basic loads occur on the reinforcement, therefore its amount is about 2-3% of the cross section along the entire length of the span. Basically use the straits of the ST-5 brand, which are stacked along the march in increments:

- With a cross section of a rod 10 mm - 120 mm.

- When the diameter of the rod 12-14 mm is 160 mm.

- When the reinforcement section is 16 mm - 180 mm.

- With a diameter of more than 18 mm - 200 mm.

In lateral projection, the frame is collected in a step of 220-300 mm. Reinforce the platforms are needed in a step of 200 mm in all directions. The fixation of the reinforcement to the mortgage nodes is aimed at not only the acquisition of an additional support, but also preventing the cracking of monolith during shrinkage. However, any drawing of a monolithic inter-storey staircase must take into account its rigid mount to the overlap. For this, mortgage bars are produced by 70-80 mm.

Metal rods form a grid laid without a lumen and placed on special locks, which are installed with a layer of concrete 30-50 mm from the edge of the formwork. Usually two rows of the mesh are sufficient for spans to 18 steps, with an increase in length, the third row of longitudinal rods is mounted. They are located longitudinally and above the main grid by 50 mm.

The grid frame at the intersections of the rods is associated with steel wire or nylon clamps. For those who know The procedure does not represent much difficult. It is desirable that the fittings are solid over the entire length of the design. But this is not always done, so there are tolerances in the splicing of mortgage components:

- magnifying bits in 24 nominal sections;

- when inserted 12 diameters, welding with one-sided seam is allowed;

- fall in 6 diameters can be fixed with double-sided welding seam.

Important! It is not necessary to reinforce the steps, however, it is recommended to be prevented under a layer of concrete metal grid 4x50 mm under a layer of concrete.

Organization of formwork

To work, it will take moisture-proof plywood or OSB, of which the chute is assembled with vertical walls. The latter are fixed between themselves, one on the step. The role of the walls can perform the walls of the adjoining. Next steps are performed in the following order:

- On the inside of the walls, the height of the carrier surface of the span is noted, which, according to the drawing of reinforcement of the monolithic reinforced concrete staircase, corresponds to the thickness of the reinforcement frame and the protective layer of concrete.

- The line mark the vertical borders of the steps. On the radius march, a cord is used for a certain length. Under the Pythagore law, the length of the inclined segment is determined from the square root of the sum of the squares of the length and height of the steps.

- Conduct vertical lines for completed marks denoting the height of the steps.

- Patterns to install vertical formwork steps, strengthened them to the walls of the gutter. Nearby standing boards are fixed with struts with clins, one for every 800 mm width of the span.

- From the bottom, the formwork needs to be pushed with racks, their number is one thing for every 1.2 square meter of the plane of the ramp. For their reliable fixation on the bottom of the formwork from the outside, transverse bars are screwed.

Filling staircase concrete

The process must be performed in one stage. Independently make a high-quality solution difficult - this is not Floor. Therefore, it is necessary to calculate the volume of formwork and order a concrete in 30 or higher class with a reserve of 10% to provide losses during transportation.

Form filling starts with lower steps, gradually moving up as the formwork is filling with the solution. In the process of concrete you need to rub, and after the end of the fill to handle vibration. Drawers are eliminated immediately by the method of adding or the next day by grouting with a mixture of M300 on the basis of cement M500.

The design is gaining rigidity in two weeks. Whole this period, the surface must be moistened in order to prevent the appearance of cracks. After frozen, the formwork is dismantled and proceed to finishing the object.