A monolithic staircase is a massive and durable concrete structure. A staircase made of concrete has the same risks of collapse as any other concrete structure. The strength of the concrete structure is ensured by the preliminary creation of its skeleton from metal reinforcement.

Exists 3 types of monolithic stairs, differing from each other in the scheme of their reinforcement:

- straight one-flight stairs without a landing;

- straight lines with a platform;

- spiral monolithic stairs.

Features of the reinforcement of a single-flight monolithic staircase without a platform

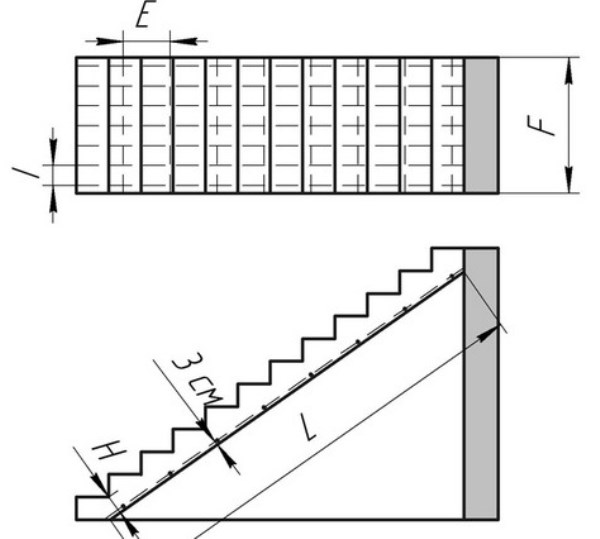

Reinforcement of a monolithic staircase, consisting of only one march, will be the simplest. The main load in such a structure will be in its lower part, therefore it is enough to reinforce such a ladder only along the lower edge. Power fittings, located along the staircase, are located 3 cm from the bottom surface of the staircase.

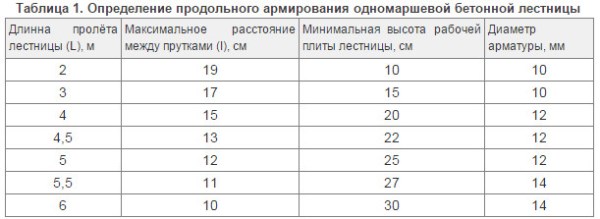

With a stairway length of 2m, the distance between the power rods is 19 cm.With an increase in the length of the flight, the distance between the rods decreases, as shown in Table 1.

The cross bars are positioned in 20 cm increments.

Reinforcement of a two-flight staircase

In this case, the reinforcement of the staircase passes into the reinforcement of the site. Since tensile forces will act on the top surface, it is reinforced at both the bottom and top edges. The upper landing reinforcement continues into the stair slab. The staircase itself also has double reinforcement.

For reliable holding of the platform, niches with a depth of 20 cm should be made at the level of its location in the walls. During the formation of the reinforcing skeleton, the rods are inserted into these niches, as a result of which the platform, after pouring the concrete, will turn out to be "inserted" into the wall. Such reinforced ends are called concrete crowns.

Reinforcement of non-standard monolithic stairs

Reinforcement of spiral monolithic staircases is a laborious process and requires strength calculation for each case separately. The reinforcement scheme in this case is calculated using special programs created for the design of reinforced concrete structures. Therefore, in this case, the calculation of the reinforcement scheme should be entrusted to a professional.

Important! To prevent crumbling of the upper layer of the steps, it is not necessary to reinforce them with a thin reinforcing mesh. To do this, it is enough to use high-quality cement for the preparation of concrete.

Reinforcing skeleton formation

Reinforcement begins after side assembly. The assembly of the formwork for the steps is carried out after the reinforcement has been laid, which should be located in accordance with the previously drawn up scheme, forming a grid with the same cells.

For concrete reinforcement, simple construction reinforcement of various thicknesses is used, which is selected in accordance with the table of the ratio of the span length and the size of the reinforcement itself. In order for the metal rods to retain their location in the thickness of the structure after pouring concrete, they are fastened together.

For fastening ordinary building reinforcement, both welding and tying the rods together with a special knitting wire are suitable. Due to the special heat treatment, such a wire is elastic and not brittle.

For speed and convenience of knitting, a hook inserted into a screwdriver is used.

Important! Welding is used only when connecting rods made of ordinary non-heated building reinforcement. If you use a hardened one, then its strength at the point of welding decreases, which will cause weak points in the structure.

It is necessary to maintain a distance of 3 cm between the reinforcement bars and the concrete surface. For these purposes, special clamps are used, which are placed under them at the intersection of the bars.

Usually, the reinforcement structure does not consist only of solid rods. Docking of the reinforcement rods is also done by welding or knitting. In the case of welding on one side, the overlap of the ends of the bars on top of each other must be at least 12 diameters of the reinforcement being connected, and in the case of a bundle, at least 50 diameters.

When fastening the reinforcement mesh of the staircase and platform, use a wire with a diameter of 6 mm.

Important! The joints of the power reinforcement should be alternated, avoiding the coincidence of the joints of two or more reinforcement in one place!

A concrete staircase with competent reinforcement is a durable structure that, after stylish finishing, will give any structure a solid and fundamental look.