Floors with each other are connected by monolithic stairs, which can be made with their own hands. The technology of work is simple, therefore the builder of low qualifications, which has experience with formwork, can very easily cope with the task.

Depending on the style of the interior, the shape of the ladder from concrete can be any: from classic to pop art.

The advantages of monolithic concrete stairs is that they do not creak, do not require constant color and withstand actually any load.

The disadvantage of such a design can be considered a greater massiveness, the consequence of this is a high consumption of material for erection. The design of the monolithic staircase can be varied - from the impressive to the aristocratic. The finish of handrails with wood or metal will give the originality of your work when building a staircase with your own hands. Strengthening the design is performed by steel reinforcement during the reinforcement of the concrete staircase.

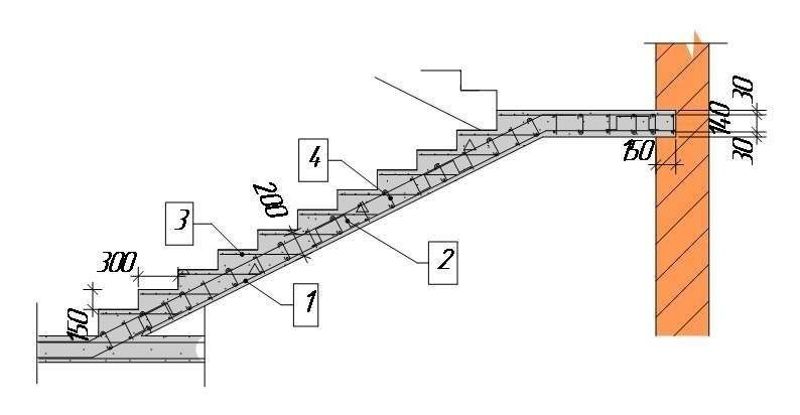

Before starting the work on the construction of the stairs, it is necessary to correctly calculate the design and mark up. When markup, the convenient location of the descents and lifts is determined. The recommended standard dimensions of the erected staircase can be attributed, mm:

- Height steps - 150;

- Width steps - 300;

- March width - 1000;

- The width of the staircase is 1100.

Designation in the Scheme: 1-longitudinal reinforcement, reinforcement O14 mm A400C; 2-retainer separation of the upper and lower reinforcement mesh; 3-reinforcement by degrees with a mesh from O4 mm BP-I; 4-vertical hooks from O4 mm BP-I.

When performing construction work for the landing in the wall of the masonry, leave a stroke for support. The most suitable option for working on the walls is considered tripartite. Opportion values \u200b\u200bare determined according to the building material building. If the brick wall is taken by 150 mm, when used in the construction of aerated concrete blocks, the support is 200 mm.

Tools and devices

For construction work on reinforcement, you need the following set of tools:

- Bulgarian or cutting metal for cutting reinforcement;

- Fixture for flexible reinforcement;

- Tools for mating rods;

- Nippers;

- Electrolovik or chain saw for cutting wooden boards, plywood, formwork shields;

- Screwdriver for assembling formwork;

- Concrete mixer for the preparation of the solution;

- Deep vibrator;

- Measuring devices (construction level, plumb or small).

Reinforcement technology

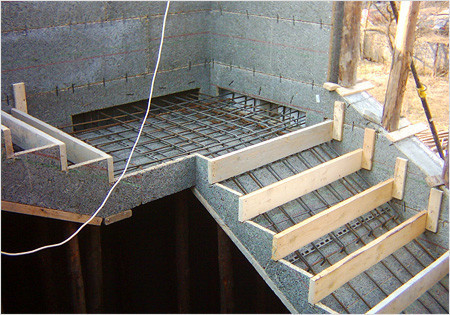

It is necessary to collect formwork using self-tapping screws: it is not recommended to use nails.

The reinforcement betrays the stiffness of the construction of a concrete monolithic staircase. The average height of the suburban floor, private houses is approximately 3 m. For reinforcement, consumables prepare. You will need:

- Armature with a diameter of 8 mm type A400C;

- Armature with a diameter of 14 mm type A40C;

- Steel wire with a diameter of 4 mm.

During the reinforcement of the landing and marches, a double grid is used. With the help of a special device intended for flexible reinforcement, a frame of a future staircase is created. For longitudinal reinforcement of the concrete staircase, the reinforcement with a diameter of 14 mm is used, and for transverse - reinforcement with a diameter of 8 mm. When making a frame try to withstand the following dimensions:

- At a distance of 0.8-0.9 m from the places of support on the platform or the foundation, the longitudinal reinforcement is located in 150 mm increments;

- The longitudinal rods of the staircase are placed in 200 mm increments;

- In the middle of the span, the longitudinal reinforcement is located in a step of 200 mm.

The grids of the reinforced ladder are installed at a distance relative to each other using special fixtures. Locks are made by reinforcement with a diameter of 8 mm. At the same time, the distance is kept in the range of 200 mm to create a thickness of the monolithic staircase. The stairs are reinforced with a flat mesh from a wire with a diameter of 4 mm.

You can remove the formwork after concreting in 3-4 weeks so that the concrete scored 80% strength.

At the end of the framework of the framework, the formwork is installed. It is recommended to use inventory formwork. Applying such a formwork, you can adjust the racks and get a high-quality design in a short period of time. Formwork shields are made of waterproof plywood. In the absence of inventory formwork, pick up a robust sheet material that can be easily put on wooden bars 140x80 mm. For the manufacture of formwork, do not skimp on the nails, the stops, soils. If the formwork is neat, then the result will be with a minimum number of defects. During the construction of the formwork, use the construction level and plumb. If the steps are curves, further finishing will become complicated.

Installation of formwork begin to spend from the staircase. After checking the horizontal structure, you can continue working on the construction of formwork for steps. When supporting a staircase march on the ground, it is recommended to use two columnal foundations.

The formwork is poured concrete class B20. Work on the pouring of concrete must be carried out in one day without a break. Improve the quality of the stairs and steps, you can speed up the concrete process using a deep vibrator. At the end of the fill, the formwork should be a week if the work is carried out in the cold season, the time to excerpt more.

In order for the edges of the steps to be destroyed, they are closed with a metal corner before conducting concreting. To make the concrete better with the metal, the "mustache" weld to the corners. Pulling the solution, they deepen into the crowd and hold motionless corners in one place.