Improving the strength of the structure and countering the deforming efforts of the primary shrinkage of the building - the function that the grid is performed for the reinforcement of the brick masonry, immersed in the cement sutures. Variable loads arising during operation, temperature fluctuations during the year contribute to the formation of cracks in ceramic and concrete masonry materials. To link a large massif of the walls to enhance the effort to the gap is intended to reinforce the masonry with a metal or basalt grid, wire, galvanized ribbon.

In the construction of bearing wall and internal partitions, the reinforcement is placed in various planes in order to harden the responsible places of masonry walls, columns, window and doorways, arched overlaps.

The horizontal and vertical reinforcement of the walls is applied depending on the nature of the existing loads. In a rather fragile hardened mass of the cement mortar, strong elements are laid throughout the length of masonry. They evenly distribute local loads on the entire design, preventing the appearance of cracks in the places of tension.

Given the possible directions of the action of critical over the magnitude of the forces, the reinforcement of brick walls is carried out in 2 planes:

- transverse (deep seam);

- longitudinal (on the surface or inside the masonry).

Additionally, the longitudinal amplification is divided by the method of orientation of the element relative to the surface of the walls to the vertical and horizontal location.

In certain places, it is important to perform proper reinforcement to maintain the integrity of the structure.

In certain places, it is important to perform proper reinforcement to maintain the integrity of the structure. What is the way to choose in a particular case and how to have reinforcing belts in the walls, after how many rows to lay them, depends on accounting in the project not only static weight loads, but also wind, snow, seismic components.

Compliance with the rules of the construction of walls and partitions refers to the creation of the conditions for the safe operation of buildings and structures, ensuring the service life of individual house-building not lower than the designed in the project.

Grid

Increase the carrier ability of the capital wall or a thinner partition, if you rein the brick masonry in the horizontal plane with a metal mesh or linked wire. This method also applies to ensure facing masonry with a plugged wall.

Construction standards so formulate the requirements for the reinforcement of brick masonry with a grid of horizontal seams:

The basalt reinforcing grid allows to reduce the amount of solution due to the thickness of the seam. In addition, it does not require additional anti-corrosion coating and thorough protection against the environment.

The basalt reinforcing grid allows to reduce the amount of solution due to the thickness of the seam. In addition, it does not require additional anti-corrosion coating and thorough protection against the environment.

It is easy to cut along the desired size of ordinary scissors. When choosing such a material, it should be borne in mind that the ratio of the strength characteristics of steel and composite 4: 1, therefore, for the same loads, the metal wire needs a smaller cross section than basalt.

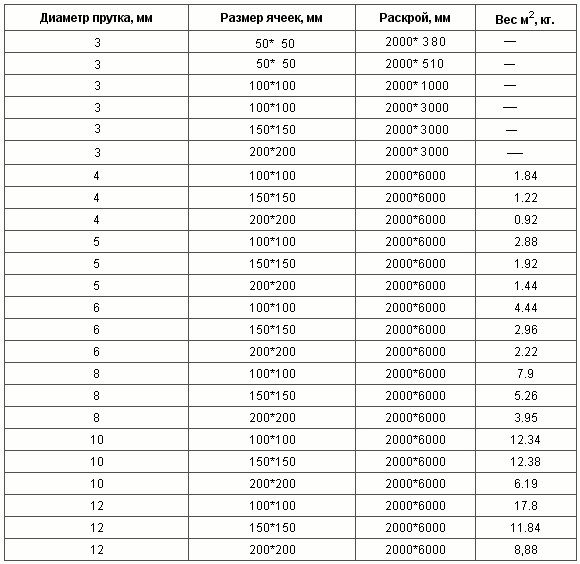

An industrial method from the steel bar is manufactured according to standard formats of cutting such options:

The best representative in its class for individual construction (where the large Ø rod is not required to ensure increased strength) is a real mesh for brickwork. It is produced in rolls, manually clipped according to the desired size, has an anti-corrosion coating, reduces the thickness of the seam compared to the wire.

Do it yourself

In small volumes, with a significant computational thickness of the reinforcement, the grid can be associated independently. It is not recommended to use regular electrical welding, as the rod loses its strength characteristics. In the factory setting, this operation is performed by the machines of point welding, which does not cause the metal ignition.

Alone, the masonry is reinforced if there is under hand such materials, the number of which is determined by the calculation + stock 10%:

- knitting wire;

- grid (steel, basalt);

- metal corner;

- steel strip;

- periodic fittings;

- steel rods;

- paint (for metal).

The need for materials of various Ø and profile is dictated by the fact that in the lower part (more loaded) deforming forces are of greater importance in all directions. Above the foundation, high resistance to bending (sizing) is achieved by laying rods of at least Ø 8 mm along the surface of the wall. With a decrease in the weight load, horizontal and inclined effects begin to prevail.

The need for materials of various Ø and profile is dictated by the fact that in the lower part (more loaded) deforming forces are of greater importance in all directions. Above the foundation, high resistance to bending (sizing) is achieved by laying rods of at least Ø 8 mm along the surface of the wall. With a decrease in the weight load, horizontal and inclined effects begin to prevail.

At the same time, the more Ø has fittings, the greater the height of the solution of the solution, which leads to a decrease in the strength of the brick masonry itself. Therefore, in most cases, a wire, a strip or a grid with a thickness of 3 to 6 mm is used.

Shape nets

In the construction of the reinforced brickwork of the bearing walls, columns, commonness is performed from the grid, which can have a different form of cells. The wire is fastened with a welding method in such a location:

- square;

- rectangle;

- zigzag.

Zigzag reinforcing laying is made only in the process of work at the construction site. Make it from the rodis from Ø 5 mm, the curvature is performed in increments of 5 - 10 cm. The size of the cell is taken from 3 to 10 cm, depending on the size of the rod, which reinforce the design.

Rectangular and square assemblies are made from wire with a thickness of 5 mm.

Important moments

In the usual operating conditions of the building, the grid is placed in the wall every 5 rows. When performing work, such basic rules are guided:

- In the case of using bricks with dimensions exceeding the usual, you can set 1 layer in 4 rows.

- Rod ends leave protruding from masonry by 2 - 3 mm to control the correctness of the finished wall. After the end of the work on the reinforcement of brick partitions, the protruding segments are removed, all seams in the location of the wire are closed with a solution of plaster or glue with tile cladding.

- In order to prevent corrosion from accessing wet air, the metal mesh is interinted into a cement solution at least 2 mm from all sides. The minimum distance between bricks will be about 14 mm, of which 5 mm on the thickness of the grid.

- For columns in areas with an increased seismic activity of loaded partitions (to reduce their thickness), vertical reinforcement of brick masonry is carried out by separate steel rods of class AI, AII, cross section 3 - 8 mm. The distance between them should not be more valve Ø: with external reinforcement - 15 times, with an internal version - 25 times.

Additional strength of the foundation of the poles is provided by a reinforcement frame or metal pillar. Brickwork is conducted around them. Building hollow support structures for construction standards are unacceptable. The strength of such empty pillars is very low, the violation of their integrity may adversely affect the strength of the whole building.

Reinforced vertical reinforcement of responsible structures is performed by reinforcement Ø 10 - 15 mm. For heavy buildings from several floors, the section may be greater than 30 mm. In this case, it is arranged a horizontal coverage of the steel corner.

You can familiarize yourself with how the fittings work in the masonry can be looking at the video: