Today, metal mesh is a popular material used in any construction work. The demand is due to the high performance and properties of the welded product, as well as a wide range of applications. The article will focus on the reinforcement mesh.

A bit of history

- The French began to reinforce building structures with metal rods in the second half of the 19th century. One gardener named Joseph was frustrated by the constant losses that resulted from the fragility of the flower pots.

- This fact led him to the idea that an iron skeleton could be inserted into the clay mass, and in 1867 he patented his invention. Although there is information that a few years earlier a plastering master from England built a house using the technology of reinforcement, but did not apply for a patent.

- The enterprising gardener did not stop at the achieved goals and continued experiments in the field of reinforcing various structures. As a result, he designed the authorship for bridges, slabs, beams, etc. Of course, those products cannot be compared in strength and other characteristics with modern structures, but, nevertheless, reinforcement began almost 150 years ago.

Reinforcement mesh classification

Reinforcement mesh is a set of perpendicularly spaced rods. The fixation of the reinforcement at the points of contact is carried out by spot welding. The main task of this product is to increase the structural strength of individual products or structures. It is subdivided according to the diameter and location of the wires, rods used and many other parameters.

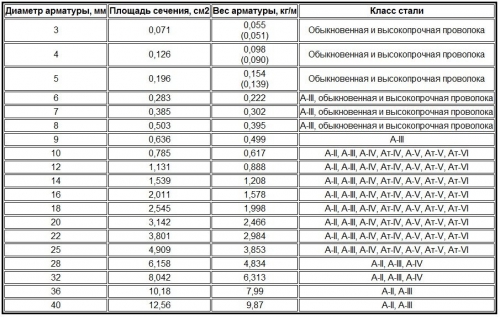

The diameter of the working reinforcement determines the mesh class:

- from 3 to 10 mm - lightweight (used in plastering works);

- from 12 to 40 mm - heavy (used for reinforcing concrete structures).

Depending on the size, the price of the reinforcing mesh varies from 4 to 200 rubles / m2.

The arrangement of the fittings can be:

- longitudinal, transverse or distribution (structural);

- longitudinal-transverse.

In most cases, the grid cells are square, rectangular, hexagonal, or some other shape. The dimensions of the cells of the reinforcing mesh can be either 5x5 mm or 200x200 mm. If the diameter of the wire is up to 5 mm, then the nets are supplied in rolls, and the rest of the products are produced in the form of a sheet (card).

The welding accuracy differs:

- usual accuracy;

- increased accuracy.

Depending on the purpose, it can be:

- masonry- it is used when pouring floors with concrete or sand-cement mixtures, for reinforcing brickwork, etc. Due to the small cross-section of the wire used, the mesh is made both in rolls and in cards. The width of the product is selected in accordance with the thickness of the brickwork, so for internal walls (partitions) the mesh size is 110-250 mm. For external walls, a mesh with a width of 380 to 640 mm is produced, which is suitable for laying one and a half, two and two and a half bricks. The length of the product is usually 1 or 2 meters;

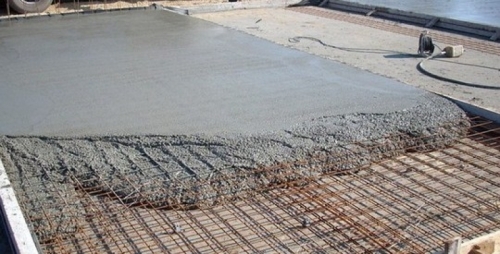

- reinforcement- provides increased strength and stability of each structural element. It is used in the manufacture of one-piece reinforced concrete structures, arrangement of the foundation. Also used on those facilities for which strict requirements are imposed. The width of the product is from 1 to 2 m, the length is up to 6 m;

- road- serves for the device of the roadbed, footpaths, access roads (both new and intended for reconstruction). It is widely used for reinforcing floors of industrial facilities. The size of the cells of the welded reinforcing mesh is in the range from 50 to 200 mm, you should know that the larger the step of the reinforcement, the lower the strength properties and resistance to mechanical loads of the finished object.

The main advantage of roll material over cards is flexibility. The wire mesh is easy to bend and cut, which allows you to give it any shape if necessary.

Many manufacturers produce meshes that not only correspond to standard standard sizes, but also manufacture products by changing the pitch and size of the cells, according to individual client requests.

Reinforcement mesh production

- For welding wire or fittings, special machines are used, which ensure high accuracy of the work performed. After all, the finished product must have the correct shape, sufficient strength and aesthetic appearance - visible deformations and irregularities are not allowed.

- The rebar welding machine is fully automated, controlled by a computer. The operator only monitors the compliance of all set parameters and welding modes.

- For welding wire with a cross section of 3 to 12 mm, a high-precision machine is used, which works by the method of resistance welding. The wire is straightened and cut to the required dimensions before being fed into the working area of the machine.

- Thanks to welding and the use of high-quality rods (without deviations in length and various contaminants), it is possible to achieve an impeccable result. Multi-electrode equipment allows for precise welding of rods without deformation, ensuring the flatness and strength of the finished product.

Steel for the production of reinforcing mesh

According to the requirements of the standard for the manufacture of meshes, the following types of assortment are used as working reinforcement:

- heavy nets- hot-rolled reinforcing steel of class A III, having increased strength characteristics, with a cross section of 12-40 mm, as well as steel of class Ab IIIC, hardened by heat treatment during rolling production.

- light mesh and distribution fittings in heavy mesh- hot-rolled reinforcing steel of classes А I and А II.

- light mesh- wire of class Bp-I, as distribution (constructive) fittings B-I.

The use of a particular type of steel is based on design documentation (depending on the operating conditions of the mesh).

Corrugated mesh

- Separately, it is worth noting the canned type of nets, where the wire has structural bends. These meshes are characterized by increased strength and shock resistance. Therefore, they are used to reinforce building objects with abnormal loads, for example, in the mining industry or when erecting buildings in a seismic hazard zone.

- The wavy structure of the wire resists deformation, even with multidirectional forces. It should be noted that we are talking specifically about mechanical strength. Corrosion resistance and other properties depend entirely on the raw materials used (types of low carbon steel).

- Such a mesh is used for sifting rock material, reinforcing concrete structures, fencing land plots, making aviaries, etc. Modern types of protection against negative influences, such as PVC or zinc coating, turn the mesh into an almost eternal material.

Electroplated reinforcement mesh

The metal mesh is used to improve the strength characteristics of various structures and building materials. The mesh must firmly "endure" all unfavorable operating conditions (atmospheric phenomena, temperature changes, humid environment, chemical attack).

In this connection, it is produced with a zinc coating, which is applied by electroplating. The advantages of this material over non-galvanized wire meshes are as follows:

- longer service life;

- resists external influences;

- will be distinguished by high resistance to mechanical damage;

- not susceptibility to corrosive processes;

- has a high degree of strength;

- has an aesthetic appearance.

Galvanized mesh does not require special storage conditions and is easily transported.

Application of reinforcing construction mesh

The grids are widely used in the field of individual, industrial, agricultural and landscape construction. Depending on the required strength indicators for the structure, the type of mesh is determined. They can be used:

- for strengthening reinforced concrete products, walls made of bricks or porous blocks, roadways, tunnels;

- when erecting bridges and supports;

- in the manufacture of concrete slabs, panels and other products;

- when installing heat-insulating material;

- for reinforcing the plaster layer;

- when arranging underfloor heating, concrete floors, screeds;

- to strengthen foundations;

- to create a frame for greenhouses and greenhouses;

- for the construction of fences, animal enclosures and other fences;

- to strengthen the walls of ditches and pits.

- The calculation of the amount of reinforcement mesh is calculated individually for each case.

Using this product will allow:

- shorten the production cycle, due to the exact geometrical dimensions and the corresponding technical characteristics;

- save time (in comparison with hand-knitted reinforcement) and rolled metal (no waste);

- improve the quality of a structure or product due to the increased strength properties of the mesh;

- significantly reduce the installation time, since the product is completely ready for use.

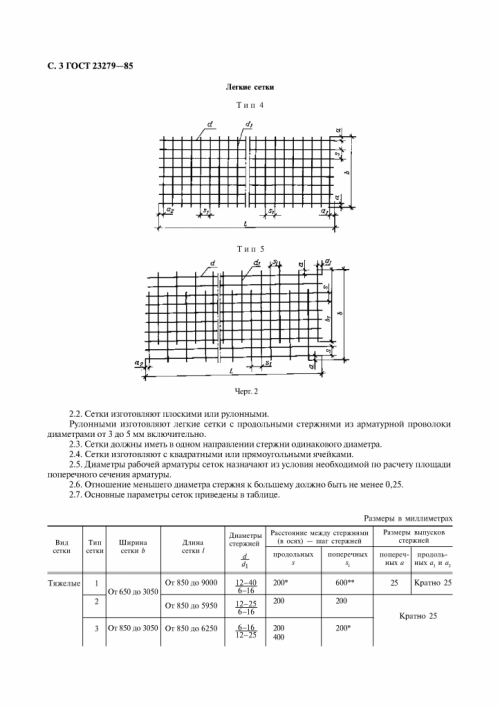

Standardization and verification of reinforcement meshes

- The production of meshes is carried out on the basis of the current interstate standardization system. GOST 23279-2012 applies to all types of meshes made from steel rods with a diameter of 3 to 40 mm inclusive. Some manufacturers produce products according to their own specifications, under which a deviation according to GOST is allowed.

- Each batch of meshes is tested for quality, which takes into account strength, size, core settlement, straightness of the structure, etc. So, to measure geometric dimensions, in particular length, width, a special tool is used: metal rulers and tape measures. The strength of the mesh is checked by free falling from a height onto a hard surface.

- Verification is carried out by random sampling of cards or rolls. If the sample taken does not correspond to any indicator, then another sample is taken. Upon confirmation of marriage, the batch is sent for recycling.

- Each package is accompanied by information, which indicates the weight, batch number, production date and brief information about the manufacturer. Also, the accompanying documents indicate technical characteristics that guarantee the quality of a particular type of reinforcing mesh.

Storage and transportation of reinforcing mesh

- For convenient transportation and movement of cards, they are packaged. The total weight of one package of reinforcing mesh usually does not exceed 3 tons. The cards are fixed to each other by means of soft wire at least in 4 points, as for the rolled mesh, it is tied in 3 places.

- The storage room for any kind of nets must be dry with normal temperature conditions. Storage of packages and rolls is carried out horizontally on wooden pallets.

- The height of the stack for cards should not exceed 2 meters, rolls are stored in no more than 3 tiers. When loading and transporting, it is necessary to act in accordance with safety regulations and observe safety measures.