We carried out all the preparatory work and installed the formwork for the pile-grillage foundation. In this same part we would like to tell you and show you our work on installing, assembling and tying the corner reinforcement and grillage piles into a single structure.

First, let's remember what a grillage is. This is the upper part of the pile foundation, distributing the load from the walls of the building onto the piles. The grillage combines separate structures into a single structure, so reinforcing the grillage is a very important and responsible process that must be approached wisely.

So, today our work began with the installation of previously manufactured elements of the grillage reinforcement frame. They had to be lifted onto the exposed formwork. It turned out that this is not such a simple task as expected. Individual elements were more than 11 meters. All parts of the frame had to fit into each other in such a way that they could then be connected correctly.

After thinking a little about how to do everything more conveniently, we took the following path. First of all, we pulled out all the formwork ties, and to be precise, the previously installed studs. With their help, placing pins along the entire perimeter of the formwork, we made a convenient base for the frame. Then, starting from the larger elements and moving on to the smaller ones, we carefully placed the entire frame on the formwork. Of course, it will be very difficult to cope alone, so it is better to think about helpers in advance.

After installation, we cut off the excess reinforcement that extended beyond the formwork and, using the most ordinary brush, removed all the dirt and rust that, unfortunately, appeared on our frame due to the vagaries of the weather, namely prolonged rainy days.

After all these manipulations, we moved on to the most important thing - tying knots or, in other words, creating rigidity of the joints. When making a grillage, special attention must be paid to them, since the strength of the entire structure depends on them.

To knit the knots of the general frame of the grillage, as before, we needed:

— chopped knitting wire 1.2x400mm (price 145 rubles per package, 1 kg)

- a screwdriver with a homemade tying hook inserted into it (bent reinforcement, diameter 6 mm)

— pliers for hard-to-reach places.

In one of our articles we have already told you how to knit reinforcement correctly, so we invite you to refresh your memory and watch this video or, if not relevant, move on.

And then we want to pay attention to the tying of the grillage nodes, namely the corners and intersections. Let us remind you that all construction of a house with your own hands is carried out on the basis of ours. So we work strictly according to it, although sometimes, to ease our conscience, we make our own additions that will not affect the overall design.

So, we were offered 2 reinforcement tying schemes.

The first diagram in the photo below represents typical units for reinforcing corners and intersections of a grillage using a P-piece reinforcement.

The second diagram, also shown in the photo below, represents typical units for reinforcing corners and intersections of a grillage using a reinforcement L-part.

The second method turned out to be closer to us, and we decided to use this particular option for tying reinforcement.

For each corner of the grillage we needed 6 L-shaped corners made of reinforcement. For each intersection we need 4 bent reinforcements. According to our design, the minimum length of the reinforcement from the bend should be 48 cm in each direction, and accordingly the total length should be at least 96 cm.

Regarding the angles. At the beginning of the work, we realized that it is better to insert the L-parts inside the frame, and then knit them. To do this, it was necessary to first move apart the longitudinal reinforcement, insert the required amount of L-parts, move them, and then tie them together using a tying wire and a screwdriver.

Thus, the corners and intersections of the grillage were reinforced. After that, we lowered the frame down into the formwork, starting from the middle and moving to the outer sides of the frame, and continued working. It was necessary to partially return the studs for screeding the formwork to their places, since according to our idea, the entire frame hung on the top row of studs.

After this, we needed to reinforce the site for the future brick shaft. Reinforcement of the widening under the chimney and ventilation shaft was additionally made with grids in the upper and lower positions from reinforcement with a diameter of 12 mm with a pitch of 200x200 mm. You can see how we did it in the photo below.

After knitting the corners, we completed the process by installing all the pins in their places.

In the process of work, we encountered the following nuances. Firstly, our piles, unfortunately, are not ideally located in all places due to the fact that when drilling in the ground we came across a lot of unpleasant foreign bodies, due to which we had to shift the location of the piles. Thus, we had places where the piles were quite close to the formwork and there was simply no room to install the grillage frame. In these places, we cut off the reinforcement and tied it together using U-shaped parts with elongated ends of at least 50 cm in different directions. Below in the photo you can see what it looks like in reality.

In one place, our pile sank quite a lot due to the floor slab in the ground, but since we ended up with 36 bored piles for the whole house, which, according to most, is considered more than enough, we didn’t worry too much. At the same time, all the piles for the load-bearing walls were in perfect order, which could not but rejoice.

Then came our initiative. This was exactly the moment when we acted for the good of our conscience and nervous system =) We decided, in addition to all the universal frame binding that had already been done, to strengthen the corners and reinforcement ties protruding from the piles with our grillage.

How we strengthened the rigidity of the corners of the grillage. To create rigidity, we added reinforcing corners with sides of 40 cm each, 4 pieces, which can be seen below in the photo. We connected the corners with the reinforcement protruding from the piles and the grillage frame. They grabbed it in about 3 places. We also used 1 corner to fasten the outer part of the corner of the grillage. This can also be seen in the photo below.

The situation was identical with all the piles. We tied all 36 piles to the grillage using similar corners. We tried not to spare the knitting wire, as this is another reason to calm our conscience and be confident in the reliability of our grillage.

Using the methods listed above, we added greater strength to our structure, which is responsible for the reliability of the entire future home. We hope that our advice will help you in construction, and our video will answer any remaining questions.

By the way, don’t forget about the ones that need to be put on after the frame is completely made. This important little detail can save you from many unpleasant moments, which we covered in one of our articles.

And finally, about the most important thing. How much does a self-made grillage frame cost? We answer. According to our calculations, the price of our monolithic grillage frame was approximately 18,000 rubles. An excellent combination of optimal price and quality that you are confident in.

And, of course, if you are interested in our DIY home construction, subscribe to our YouTube channel and read our blog.

P.S. You can read the final part of the article about the grillage.

Best wishes,

Yana and Zhenya Shigorev.

Not a single modern house can now be imagined without a foundation. It is the foundation that collects all the loads from the supporting structures and transfers them to the soil. There are different types of foundations.

In some cases, it is appropriate to create monolithic strip foundations, while in others, solid monolithic structures are used. We will now talk about the features of a pile foundation, as well as such an important process as the reinforcement of all load-bearing structures of the foundation.

Features and design of a pile foundation

A pile foundation is one of the types of load-bearing supporting structures on which the rest of the structure is then mounted.

Just like other foundations, this type of foundation is designed and built using SNIP and other regulatory documentation. However, the drawing, calculation and type of specific elements will be slightly different from a strip or solid one, since its tasks are slightly different.

Unlike strip load-bearing structures, in pile foundations the load-bearing elements and main stress transmitters are the piles themselves.

They are great for use when it is necessary to install a house on soft soils. In such cases, the large base of strip foundation models is too expensive, but the creation of point piles is considered more appropriate.

When constructing such a structure, bored piles, driven piles and several other manufacturing technologies are used. Their calculation and standardization is regulated by the appropriate SNIP.

It is prohibited to create such important elements of a future structure without taking into account regulatory documentation, as this can lead to quite unpleasant consequences. Moreover, it does not matter what type of structure you have to build; in any case, SNIP will be a priority document.

In addition to a pile foundation consisting of several dozen elements, not a single pile foundation structure can do without a grillage. It is worth understanding that the type of pile foundation involves installing the piles directly at a distance of approximately 2-4 meters from each other.

The specific distance is regulated by the drawing, SNIP, type of foundation and several other parameters. But in any case, it will be quite impressive.

To put this whole structure together, they use the creation of a grillage tying belt or slab. Moreover, it does not matter whether a grillage is used for tying bored or driven piles. In any case, its presence is simply necessary.

The grillage itself is a consistent and rather impressive part of the pile foundation; it can consist of a large number of beams or a monolithic slab.

It is the grillage structure that bears the entire main load from the supporting structures of the house, and it, in turn, transfers it to the piles, which put pressure on the ground and distribute the load over the soil.

Pile foundations are characterized by the use of different types of piles (bored, driven) and different materials. In this case, we consider only the most durable, reliable and in need of reinforcement.

Reinforcement of piles and the entire pile foundation itself is an absolutely necessary process. Without reinforcement, although concrete performs its functions, it is not as good.

The fact is that concrete itself is a fairly strong material, but any SNIP, GOST or official research results indicate that, despite its strength, it does not work well in bending. Namely, bending loads put pressure on the structure of the grillage pile foundation.

If all these structures are not reinforced, there is a high risk of their destruction or serious damage. In this case, the entire house will have to be considered unsafe, since the foundation is perhaps its most important part.

To implement high-quality reinforcement, a specific calculation is used. It is also regulated by the current design drawing, as well as its type and regulatory documentation, which will give you all the additional information (SNIP, GOST, reference books, etc.).

For reinforcement, welded reinforcement frames are used in the form of a mesh with a certain pitch. The specific type of metal or, its length and all other parameters determine the design calculation. The type of reinforcement section determines how the welded mesh will be assembled.

Types and differences of grillage foundations

As we mentioned above, there are several types of grillage-type foundations, as well as grillage and pile structures. All of them are of quite serious importance, not only due to the features of their design, but also due to how the welded mesh will be used for their reinforcement.

It is quite obvious that a strip grillage differs in shape, dimensions and purpose from a solid grillage. This means that the welded mesh for reinforcement will be different.

This type of foundation starts from piles. Piles can be assembled and installed according to:

- Drilling technology;

- Hammering technology.

Bored construction technology is characterized by the creation of piles with a powerful bottom cushion. They are formed using the technology of immersing special tools into the soil and displacing it, and then laying the reinforcing mesh and concreting the entire structure.

Calculation of grillage mesh reinforcement

Now let's move on to the most important point - the calculation of the reinforcing mesh (frame). The welded mesh for the grillage will differ primarily depending on its type.

The use of bored, driven or other types of piles will be of secondary importance, since in this case the piles are only required to release the connecting reinforcing pins to which the grillage mesh will be attached. But nothing more.

The calculation is performed according to the drawing of a specific grillage type. Thus, a linear grillage has the shape of a large beam. He ties all the piles, forming a kind of belt. Columns in load-bearing frame buildings are tied using the same scheme.

The lower part of the mesh will be assembled from thicker reinforcement with a diameter of 20 mm. The upper one will have a cross-section of 8-15 millimeters.

Since the main loads on surface bending will put pressure on the grillage tape only in places of contact with the piles, serious reinforcement should be done in the sections of the tape under the piles.

Moreover, it is enough to just stretch the reinforcement 1.5-2 meters from the center of the pile along the tape in both directions. In other places, making such powerful structures of the upper mesh is recommended, but not at all necessary.

In this case, the welded mesh frame is calculated quite easily. The width of the tape and its height are taken into account. The reinforcement of the lower level is laid in increments of 8-10 cm. As a rule, at least 4 rods go to the lower mesh of one of the grillage strips. The top one can take up to 6 rods.

This calculation applies to tapes 25 centimeters wide. If the tape is much wider, then you will have to spend more reinforcement on it. Also, the upper and lower mesh are tied and fastened to each other with persistent clamps made of durable reinforcement. This should also be taken into account.

Thus, by calculating the length and width of the grillage strips, as well as creating a drawing of its grid, you can perform a full calculation of the reinforcement, find out the amount of material needed, its cost and a bunch of other useful points.

For a solid grillage, since it is essentially an enlarged monolithic floor slab, the welded mesh will be slightly different. Firstly, it will cover the entire area of the house. Secondly, it must be very durable and reliable.

Here, in increments of 20-25 cm, it is necessary to lay reinforcement with a minimum diameter of 20-25 mm. The reinforcement is laid crosswise to create an extremely strong foundation.

But the upper mesh has interesting features. It is not always necessary to install it over the entire area. This is explained by the fact that the lower reinforcement mesh absorbs almost all loads.

Any upper mesh must absorb bending loads that come from the interaction of load-bearing structures and the upper elements of the building. This means that it needs to be installed only near the load-bearing elements that will be placed on top or the load-bearing elements that will support it.

In monolithic frame houses, the upper reinforcement mesh of the floors covers only areas of 2x2 or 3x3 square meters, with a center in each supporting column. All other places are either equipped with a safety net made of thin reinforcement, or are left without it altogether.

If you calculate the dimensions of a solid grillage, as well as its usable area, you can find out all the information you need in the same way.

Grillage reinforcement technology

It is quite easy to describe the reinforcement technology itself, since it is, in fact, almost identical in all cases.

Stages of work:

- We assemble the formwork and ensure its strength and reliability.

- We assemble the lower frame of the reinforcing mesh.

- We install clamps, supporting posts and other elements.

- We assemble the top one in the right places.

There are no similar entries.

A pile foundation is a universal foundation for the construction of brick (read about it separately), wood, aerated concrete (read about it separately) and foam concrete low-rise buildings in any ground conditions. Such bases are also used for other structures (for example, fences). The strength and reliability of the pile foundation directly depends on the grillage, the reinforcement technology of which we will talk about in this article.

You will learn why a pile-grillage foundation is needed, what materials are used for this and how the process itself is performed. Diagrams and drawings will be provided that explain all the nuances of reinforcement of a monolithic grillage.

1 What functions does the grillage perform and why is it reinforced?

The grillage is a strip structure (we read separately about how a regular grillage is reinforced), connecting free-standing piles to each other. By tying the supports, they receive additional spatial rigidity and resistance to overturning loads. The grillage also acts as a supporting surface on which the walls of the building are erected.

1.1 What and how to reinforce?

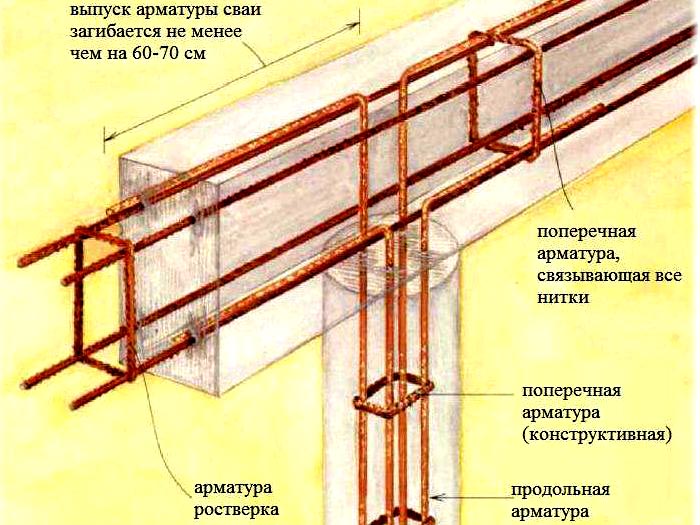

Reinforcement of the strip grillage is carried out using a spatial reinforcement frame, consisting of two longitudinal reinforcement belts (upper and lower), connected to each other by horizontal and vertical jumpers.

Longitudinal belts are made from reinforcement bars of class A3 (hot-rolled corrugated profile), the diameter of which is 13-16 mm. It can be used, as confirmed by reviews of the successful operation of such pile-grillage foundations on specialized forums.

Connecting vertical and horizontal jumpers can be made in two versions - in the form of separate rods of reinforcement welded to the longitudinal chords (the diagram shows the configuration). In this case, it is necessary to use rods of the same standard size as when arranging the longitudinal belt.

The frame can also be connected by jumpers made of rectangular reinforcement bent into clamps (diagram below). With this approach, smooth rods of class A2 (diameter 8-10 mm) are used. Bent clamps are labor-intensive to install, but due to the smaller number of welds, they are more reliable and durable. Fiberglass reinforcement that cannot be bent is not used to create clamps.

According to the provisions SNiP No. 2.03.01 “Manual for the design and arrangement of pile-grillage foundations”, when installing the reinforced frame, it is necessary to observe the following step between the constituent elements:

- the number of rods in the longitudinal belts is at least 4, the distance between them is up to 10 cm;

- the pitch between the transverse jumpers of the longitudinal belt is 20-30 cm;

- the step between the vertical connecting jumpers is up to 40 cm;

- protective layer of concrete - at least 5 cm.

The protective layer is the distance between the outer contours of the reinforced frame and the walls of the concrete body of the monolithic grillage. If the protective layer does not have the required thickness, two problems will arise - the frame will not be able to correctly redistribute the loads acting on the grillage and the reinforcement will be excessively susceptible to corrosion under the influence of moisture penetrating into the micropores of the concrete.

To create a protective layer along the bottom edge of the grillage, special plastic mushroom stands are used, which lift the reinforcement above the formwork. The use of pieces of brick for these purposes is not permitted.

1.2 How to calculate the amount of reinforcement?

As an example, we give for a monolithic grillage with a perimeter of 8 * 6 m. We use the conventional dimensions of the strapping 40 * 40 cm. The reinforcement frame for such a strapping will consist of two longitudinal belts of 3 A3 rods with a diameter of 14 mm in each (the pitch between the rods is 10 cm, 5 cm on each side eats up the protective layer of concrete). The belts are connected by jumpers made of A1 reinforcement with a diameter of 11 mm, located in increments of 20 cm.

The calculation is performed using the following algorithm:

- We determine the total length of the rods in the upper longitudinal belt. To do this: a) determine the perimeter of the grillage: 8+8+6+6 = 30 m; b) we calculate the length of 3 rods: 3*30 = 90 m; c) calculate the length of reinforcement A3 for both belts: 90*2 = 180 m.

- To connect the rods of the longitudinal belt, we will need jumpers 30 cm long, which will be located in increments of 20 cm. We calculate their number for both contours of the grillage: 2*(30/0.2) = 300 pcs, after which we calculate the total length of the transverse jumpers: 300* 0.3 = 100 m.

- It remains to calculate the length of the vertical jumpers connecting the upper and lower contours of the frame to each other. But since in the example a rectangular grillage is calculated, their number and length will be identical to the transverse lintels. If a grillage of rectangular configuration is used, the calculation is performed according to the formula specified in point No. 2.

As a result, the calculation showed us that the grillage reinforcement requires 180 m of A3 class reinforcement and 200 m (100+100) A2 rods with a diameter of 11 mm. Calculations may also be required if you do not plan to use welding. It is carried out taking into account the fact that about 40 cm of material is required for one connection: we determine the number of connections: 4*(30/0.2) = 600 pcs; and calculate the material consumption - 600 * 0.4 = 240 m.

1.3 Features of grillage reinforcement (video)

2 Technology of reinforcement of a monolithic grillage

The amplification of the grillage begins after all the previous stages of arranging the pile foundation have been completed - installation of piles, their trimming and arrangement of formwork. You must have a ready-made formwork, inside which the reinforced frames of the piles protrude to a height equal to the cross-section of the framing.

When assembling the frame, the reinforcement can be tied together using wire or the rods can be connected by welding. There is no significant difference in the joining method - it is often argued that a welded frame, due to the lack of elasticity, resists deformation worse than a ductile structure, however, in industrial multi-story construction, the frames of pile-grillage foundations are always welded, so these fears are groundless. In addition, welding is a more practical and quicker method to implement.

Grillage reinforcement - step-by-step instructions:

Assembling the reinforced frame on straight sections of the grillage is quite simple to perform. Difficulties arise when reinforcing the corners, which must be further strengthened, since this part of the frame experiences maximum loads.

Corners and places where the internal walls of the frame meet the external ones cannot be reinforced with overlapping reinforcement. In these areas it is necessary to lay solid rods curved in an L or U-shaped configuration. A diagram of the correct reinforcement of the corners of a pile grillage is shown in the image.

A grillage is a device that evenly distributes the load of a house on the pillars or foundation piles.

There are 3 most popular types of grillage: strip, slab and pile. The grillage reinforcement must be carried out exactly according to the project, which must be drawn up in advance. It should make a preliminary calculation and analysis of the foundation of the future house. Because if you neglect this data, you can make a mistake in the basis, which will lead to undesirable and irreversible consequences.

The process of reinforcing slab and monolithic grillage

Scheme of reinforcement of the glass part of the grillage: 1 – transverse reinforcement mesh; 2 – spatial frame; 3 – meshes of indirect reinforcement.

When reinforcing a monolithic grillage, it is necessary to lay 2 layers of horizontal mesh, and make a protective layer between them. Reinforcing bars must be installed at a distance (step) of 200 mm. The joints themselves cannot be welded, because heating them leads to a loss of metal strength. Therefore, for reinforcing connections it is necessary to use knitting wire, which is tied with special hooks. The reinforcement frame should be made spatial; for this, “vertical distances” are used, which are made from cut pieces of reinforcement. These segments are not made very long so that the resulting connection has a sufficient margin of strength and stability.

The vertical outlet from the foundation piles must be connected to horizontal rods. This is also done using knitting wire. Reinforcement can be considered complete only when all the rods are placed in the formwork and they do not sag anywhere when pressure is applied to them. After this, it is necessary to check the protective layer in the lower sections of the connections.

Once you are convinced of the reliability of the structure, you can begin the process of concreting it.

Return to contents

The process of reinforcing a strip grillage

Reinforcement technology is practically no different and is similar to slab reinforcement. The differences will be in the formwork installed, because it will significantly limit the work area. Within the formwork itself, it is imperative to maintain layers of protection on all sides. This must also be done using a knitting wire. The rods must be overlapped. The amount of overlap should be equal to or slightly greater than 50 times the diameter of the rods used.

To do the reinforcement correctly, you must remember that the rods that will be laid horizontally should not sag. At the moment when the concrete pouring takes place, the rods must necessarily occupy the position specified in the project. In a strip foundation, you need to place the vertical rods correctly, because... they will ensure the rigidity of the rods. Therefore, their presence in the strip foundation is mandatory.

The main difference between slab and strip grillages is that in the first option, all the heads are connected at once. With the tape version, only adjacent structures are connected with a grillage.

If you are reinforcing a grillage with a pile foundation, this can be done from different materials. The material from which the piles are made is mainly concrete. The reinforcement process is quite simple. For a pile foundation, it is necessary to prepare reinforcing bars, the diameter of which should be 1.0-1.5 cm. In order to tie the piles, which can be 2 meters high, together, the reinforcement should be placed at a distance of 45-55 cm from each other. The frame made of reinforcement for the pile foundation must be made so that the protrusions of the vertical rods are 15-20 cm. It will be necessary to tie it to them.

Return to contents

Features of the work

The main problem that arises during the construction and calculation of the foundation is the choice of the cross-section of the grillage itself. It is necessary to take into account the fact that an air gap must be made under the strip grillage, the size of which must be at least 15 cm. Very often during construction there may be a desire to combine a slab and strip structure. This can lead to sad consequences in the future, namely: when the soil freezes in winter, the foundation strip will rise, and the slabs will prevent this. Which will lead to the rupture of the supports, and this will cause further destruction of the entire foundation, and then the destruction of the house.

To decide on the size of the transverse one, you first need to make a house design: decide on the thickness of the walls to be erected, and the appearance of the building itself (number of floors). You need to know the slope of the construction site and the type of soil. If a strip foundation is used, it must match the thickness of the house wall itself. In this case, it is necessary to take into account the insulation of the wall and its finishing. If there is a slope at the construction site, then you must immediately take into account that the strip foundation will have different heights along its entire length.

If the slope of the construction site is very large, then the grillage can be made of a stepped structure. In this case, the support rods must be deepened by no less than 20-25 cm. The support must be inserted into it by 5-7 cm. When choosing the height of the steps, it is necessary to determine the thickness of the wall masonry. The steps should not depend on the location of the supports themselves; their location should be free. When the wall is being built at the very place of the step, it is necessary to lay rods to prevent the appearance of cracks. The location of this reinforcement should be in the same plane with the building and only in the area of the steps.

Return to contents

Calculation of slab foundation reinforcement

To calculate the amount of reinforcement, you need to be guided by the type and shape of the foundation. They can be determined based on the load on the foundation and the bearing capacity of the soil. As an example, it can be done for a house whose size is 6x10 m and has 2 internal walls.

Rods that have a ribbed surface will be used. Class A3 fittings meet these requirements. took a diameter of 10 mm. You need to remember the fact that the thicker the rods, the stronger the foundation will be. The thickness of the reinforcing rod must be selected taking into account the weight of the house and the type of soil on which it is located. If the soil on which the future structure will be located is quite dense and its bearing capacity is high, then the deformation of the foundation will be less. When building a panel, frame or light wooden house, where there will be soil with good bearing capacity, it will be possible to use rods with a diameter of 10 mm. If a slab foundation and soil with weak bearing capacity are used, then in this case it is necessary to use reinforcement with a diameter of 14-16 mm. The mesh pitch of the reinforcement frame is 20 cm (0.2 m). The quantity calculation will look like this:

((10/0.2)+1) = 51 pcs. rods 10 m each.

((6/0.2)+1) = 31 pcs. rods 6 m each.

51 + 31 = 82 pcs. rods

Since the foundation is slab, it uses 2 reinforced belts: lower and upper. It needs to double the number of rods. It turns out 164 rods, of which 102 pcs. 10 m long and 62 pcs. 6 m long. The result is:

102 * 10 = 1020 m.

62 * 6 = 372 mm.

1020 + 372 = 1392 m.

The lower grid of rods must be connected to each other. Connections are made at the intersection of the transverse and longitudinal rods. The number of connections is calculated:

51 * 31 = 1581 connections.

If a slab is used, 200 mm thick. And the distance of the slab surface to the frame is 50 mm, then 200 – 50 – 50 = 100 mm or 0.1 m.

1581 * 0.1 = 158, m.

158.1 + 1392 = 1550.1 m - the required number of rods for a slab foundation.

The knitting wire is calculated:

51 * 31 * 2 = 3162 connections.

You need to connect with double folded tie wire. The length of a piece of wire is 15 cm. Multiplied by 2, the result is 30 cm. The number of ties at the joints is multiplied by the number of connections and the result is 6324 pieces.

6324 * 0.3 = 1897.2 m of wire.

We will send the material to you by e-mail

Before building a house and deciding which foundation to create - or a pile foundation, novice builders are faced with such a concept as a grillage. Below we will look at what a grillage is and its necessity when constructing the foundations of a building.

General view of the monolithic structure

A grillage is a horizontally located element of the pile foundation of a structure (a kind of belt or cushion), which takes on the entire load of the building and, evenly distributing it, transfers it to the support columns. This is achieved by tying the piles into a complete structure. Since a grillage on a pile foundation increases the strength of the building, it is necessary to ensure sufficient rigidity for all connection points.

The advantage of such a foundation for a building is its durability, strength and the ability to build on sandy and clay soils, as well as on quicksand. In addition, due to the insignificant amount of preparatory work and the concrete mortar used, such a house foundation design is considered a less expensive option compared to other types of foundations.

To better understand what a grillage is, you need to know its classification into the following types:

- at the place of arrangement;

- on the building materials used;

- by constructive solution.

By location:

- Shallow. This is the optimal type of construction to obtain reliable stability. Since the base of the belt is located directly on the ground, the entire future load from the structure will be distributed not only between the piles, but also over the entire foundation.

- Recessed. In this case, part of the structure with a sole width of 50 cm or more enters the ground. These are used for the construction of multi-story buildings on unstable soils.

Video: grillage device for a wooden house

Metal belt for foundation

Metal sheathing is made of channel, I-beam or square profile and has high strength and rigidity. As a rule, this design is used when constructing pile-screw foundations for. The channel is installed on the heads of the supports and fixed by means of a welding connection.

A metal belt is used mainly in a hanging version. However, recently such structures have been used very rarely, since due to the heaviness of the material, the use of special lifting equipment is required, which is not economically profitable. In addition, the metal is at risk of corrosion processes.

Types and purpose of grillages

Grillage structures vary in type and purpose. When choosing the required design, many factors are taken into account.

Strip foundations with grillages

For buildings, a fairly strong and reliable support is pile foundations with a strip grillage, for the construction of which two technologies are used. One of them is used when arranging foundations above ground level, and the second is used at the stage of creating a lattice structure that takes on part of the load.

A strip foundation is the best option for constructing a foundation on slopes and areas with complex terrain, since it does not require complex preparatory work to plan the site using special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation when building a house requires the following:

- Sand cushion, the thickness of which is 200-300 mm. It is created under a concrete frame and piles to protect them from the destructive effects of ground moisture.

- Waterproofing gratings and supports, for which polyethylene film, roofing felt or asbestos-cement pipes are used.

When arranging the foundation, it is necessary to carefully consider the strip grillage, as well as its thickness and other parameters.

For the fence

The installation of a grillage for fences is necessary for complete protection of the structure, which the plane of the fence cannot provide. The creation of the belt is due not only to provide protection from external factors, but also to ensure that, for example, pets cannot get out of the area. The reasons may be any, but the execution must always be of high quality, ensuring the strength and durability of the structure.

In principle, a grillage for a fence is practically no different from the belt used in arranging the foundations of houses. The same design and building materials are used here and similar functions are performed.

For pile foundation

The need to install a columnar foundation with a grillage is directly determined by the specific design of the building, its weight and the rigidity of the structure’s frame. To prevent the support columns from collapsing, they are bound with a monolithic reinforced concrete, metal or even wooden belt.

Several schemes for pile foundations of buildings are used in construction:

- Columns with a hanging belt are buried in the ground. This scheme is used in 90% of all pile foundations;

- The pillars rest on a crushed stone embankment without going deep into the ground. With this scheme, high rigidity of the base of the house is ensured, which makes it possible to minimize the likelihood of subsidence of the structure;

- No grillage. This option is used for the construction of small houses.

On a note! Supports for the columnar base of a building can be combined, for example, brickwork is combined with pouring concrete mortar or a base made of rubble. In principle, this does not change the properties of the foundation, but the arrangement process is greatly simplified and the cost is reduced.

Pile-grillage foundations

Grillage technology with bored piles

Arrangement of foundations with a grillage on bored piles is mandatory when constructing buildings on uneven terrain, slopes and unstable soils. These structures are the best option for the construction of both small houses and medium-sized permanent structures. Bored foundations with a grillage have a higher load-bearing capacity than monolithic and strip foundations, and they are cheaper.

Bored piles are able to withstand a load of about 1500 kg. To erect a medium-sized structure, you will need several dozen columns, the diameter of which can reach up to 150 cm and the length up to 40 m.

To arrange the base of the building, no major excavation work is required. Each pile is waterproofed with two layers of roofing felt or roofing felt and fixed in a non-freezing layer of soil. Waterproofing helps protect concrete from destruction and reduce soil pressure on supports.

Advantages of a foundation on bored supports:

The tops of the installed pillars are cut off at the same level, after which they are united by a common belt. A grillage on bored piles allows for uniform distribution of the load exerted by the weight of the structure throughout the entire base of the building. The construction of a pile-grillage foundation can be seen in the video below:

The disadvantage of this design is the fact that due to the presence of free space between the floor and the ground, a bored foundation with a grillage needs to be insulated. This leads to additional labor and material costs.

Grillage on screw piles

The advantage of foundations on screw piles is that their installation does not require excavation work, and they are usually used on clayey and heaving soils. After the supports are installed, their heads are cut to one level and a lattice belt is installed.

Monolithic reinforced concrete and concrete structures for screw piles are made extremely rarely, since this type of support is used for the construction of lightweight structures. Most often, a pile-screw grillage is made from a metal corner or channel.

Before installing the grillage on the heads, metal platforms are welded to them, the size of which should allow the axial displacement of the supports to be corrected. Next, all the piles are tied with a channel or angle, resulting in a strong and reliable structure.

Important! Before installing the foundation and grillage on screw piles, it is necessary to carry out anti-corrosion treatment of all metal structural elements. This will significantly increase the service life of the structure being built.

Main dimensions and dimensions

To create a strong and durable foundation, it is necessary to make the correct calculations. The shape and dimensions of the grillage used are determined by the design features of the building being constructed, the loads on the foundation, and the number and location of piles.

The grillage is created in the same way as the strip foundation structure. The height of the grillages for pile foundations directly depends on the level to which the structure should be raised from the ground, as well as on its weight. You can independently calculate a structure resting on the ground or slightly recessed. In the case of constructing a hanging belt, it is better to entrust the calculations to specialists, since they are very complex for a non-professional.

- B – minimum permissible height for belt support;

- M – weight of the structure of the structure without taking into account the supports used;

- L – belt length;

- R – soil strength at the surface of the earth.

Reinforcement frames for belts on a pile foundation are created in the same way as for construction on a strip foundation. The structure requires longitudinal (working), horizontal and vertical transverse reinforcement. The total cross-section of the longitudinal reinforcement must be at least 0.1% of the cross-section of the belt. To select the cross-section of each rod and their even number, an assortment of reinforcement is used.

Main manufacturers and standard series of pile grillages

For private or small buildings, you can make lattice belts yourself directly at the construction site, but when constructing industrial buildings, multi-story buildings, etc. use factory-produced designs. Among the main manufacturers of precast concrete grillages from 35 tons, the following companies can be distinguished:

- JSC APSC "Gulkevichsky" ;

- CJSC "OBD" ;

- JSC "T-Beton" ;

- LLC "LSR. Construction-Ural" ;

- LLC "ZKPD Tomsk House-Building Company" ;

- JSC "PZSP" .

| Series | Description | |

|---|---|---|

| Monolithic reinforced concrete grillages Series 1.411.1-1/89 | For the installation of foundations for prefabricated reinforced concrete columns of single- and multi-story industrial buildings of the II 20-1/70, II 20-2/70, II 20-3/70 series. | Structure supports of the II 20-1/70, II 20-2/70, II 20-3/70 series have a cross-section of 400*400 and 400*600 mm. and must be embedded into the foundation at 600 mm. |

| Series 1.011-6 | Made from heavy concrete class B 12.5 | Square piles 300*300 and 350*350 mm. |

| Series for metal grillage: 3.407.9-1581 | To operate the structure at temperatures: ● up to - 40˚C the grillage is made of carbon steel grade VSt 3, corresponding to GOST 380-71; ● below - 40˚C for the grillage, low-alloy steel grade 09G2S is used, which corresponds to GOST 19281-73 and 19282-73. |

|

The name used to designate typical grillages for pile foundations includes the mandatory letter indices RS and RB and serial numbers. Markings RS1 – RS5 are used on square supports, and RB – for rectangular piles.

Important! If it is necessary to order grillages from 50 tons, the concrete manufacturer must be chosen especially carefully to ensure the strength and durability of the entire structure.

Basic provisions for the design and calculation of a pile grillage

When installing a pile-grillage foundation, it is necessary to know the basic requirements for the grillage and carry out competent calculations of the entire structure. It is also necessary to have an as-built diagram for the grillages, which indicates all the main structural elements. An important point when designing the foundation of a building is the accurate calculation of the required number of supports for each specific type of structure. The calculations are based on the total weight of the structure and the bearing capacity of the soil. The mass of the house must be divided by the bearing capacity of the soil and we obtain the area of the designed foundation. To determine the safety factor, the foundation area should be increased by 30%. To calculate the required number of support columns, the area of the base must be divided by the volume of each pile, and the following conditions must be met:

- supports must be installed in all corners of the structure being constructed;

- piles are mounted at the intersection points of the building walls;

- According to SNIP, the distance between the piles in the grillage is 2-2.5 m.

The connection between the pile and the belt can be rigid or free. In the case of a loose connection, the heads of the supports enter the grillage to a depth of 50-100 mm. This type of fastening is suitable for centrally loaded support columns.

With a rigid connection, the pile head is broken and the reinforcement is exposed, after which it is embedded into a concrete or reinforced concrete grillage. This type of fastening is performed in cases where:

- the installation of pile foundations with grillages is carried out on unstable soils;

- horizontal loads are placed on the supports;

- combined or inclined supports are installed at the base;

- support columns work with pull-out loads.

Calculation example

Let's consider an example of calculating a pile foundation with grillages for a one-story brick house with a hip roof made of metal tiles. The building has two reinforced concrete floors with a thickness of 220 mm. The dimensions of the house in plan are 6*9 m, the thickness of the load-bearing walls is 380 mm. The total height of the floor is 3.15 m, from floor to ceiling – 2.8 m, and the total length of the partitions inside the building is 10 m (there are no internal walls in the rooms). The site contains a refractory mixture with a porosity of 0.5 and a depth of 3.1 m.

We pre-set the grillage width to 400 mm. and height 500 mm. The length of the support is 3 m, and the cross-section is 50 cm. We focus on the pitch of the support piles – 1.5 m. To determine the total number of piles, it is necessary to divide the length of the grillage by the pitch of the supports and add 1 (if necessary, round the resulting value down to the nearest whole number numbers – 30/1.5+1≈21).

- Support area, m 2 3,14*0,52/4 = 0,196

- Perimeter, m - 2*3,14*0,5 = 3,14

- Grillage weight, kg- 0.4 m.*0.5 m.*30 m.*2500kg/m 3 = 19500

- Weight of supports, kg- 21 * 3 m * 0.196 m 2 * 2500 kg/m 3 * 1.3 = 40131

- Weight of the building, t- Weight of supports + weight of grillage + sum from the table ≈ 224

To calculate the volume of the grillage and other parameters, it is necessary to determine the mass of the structure without foundation supports. As a result, we obtain M = 204 tons. The width of the salting is equal to M / (L * R) = 204/ (30*75) = 0.09 m. Such a belt cannot be used for construction, in this case, since the overhangs of brick walls should not be more than 40 mm. Therefore, we set the width to 400 mm, but the height remains 500 mm.

Article